Introduction

In the world of industrial safety, combustible dust is a topic that often flies under the radar, yet it poses significant risks to workers and facilities alike. Among various types of combustible dust, combustible metals stand out due to their unique properties and the dangers they present. Understanding these materials and implementing effective dust collection strategies is essential for maintaining a safe working environment.

Understanding Combustible Dusts

Combustible dust refers to fine particles that can ignite and cause explosions when suspended in air at certain concentrations. These particles can originate from various sources, including metals, wood, plastics, and food products. When discussing combustible metals specifically, it's crucial to recognize that these materials can create hazardous situations if not properly managed.

Risks Associated with Combustible Metals

The risks associated with combustible metals are particularly alarming given their potential for rapid combustion and explosive reactions. Metals such as aluminum and magnesium are notorious for their flammability when reduced to fine dust particles; a seemingly innocuous accumulation can lead to catastrophic events if ignited. Therefore, understanding the specific risks tied to different combustible metals is vital for any industry handling these materials.

Importance of Effective Dust Collection

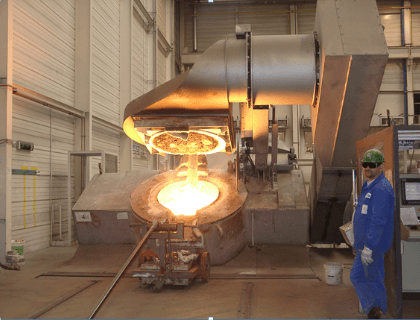

Effective dust collection systems are not just a regulatory checkbox; they are critical components in safeguarding lives and property within industrial settings. By implementing comprehensive dust collection solutions tailored for combustible metals, companies can significantly reduce the likelihood of fires or explosions caused by accumulated dust. Investing in robust systems not only ensures compliance with safety standards but also fosters a culture of safety awareness among employees.

Common Combustible Metals

When it comes to industrial safety, understanding combustible metals is crucial. Unlike your regular metals, these fiery materials can ignite and cause catastrophic explosions if not handled properly. A comprehensive grasp of the properties and risks associated with combustible metals can make all the difference in maintaining a safe work environment.

Overview of Combustible Metals

Combustible metals are those that can burn or explode when they are in a finely divided state, such as dust or powder form. The most commonly recognized combustible metals include aluminum, magnesium, titanium, and zirconium. Each of these metals has unique characteristics that contribute to their combustibility, making it essential for industries that handle them to implement stringent safety measures.

Examples like Aluminum and Magnesium

Aluminum is one of the most widely used combustible metals in various industries due to its lightweight nature and excellent corrosion resistance. However, when finely powdered or in dust form, aluminum poses significant fire hazards—especially when exposed to heat or sparks. Magnesium is another notorious example; while it’s known for its strength and lightness, its dust can ignite easily and burn with intense heat, creating a dangerous situation if not properly controlled.

Risks and Precautions

The risks associated with combustible metals cannot be overstated; even small accumulations of metal dust can lead to explosive reactions under certain conditions. To mitigate these dangers, facilities must implement rigorous housekeeping practices to prevent dust buildup and ensure proper ventilation systems are in place. Regular training sessions on handling combustible metals will also empower employees to recognize potential hazards before they escalate into serious incidents.

Wood Dust: A Sneaky Culprit

Wood dust may seem harmless, but it’s a hidden danger lurking in many workplaces. Unlike combustible metals, which are often recognized for their risks, wood dust can accumulate unnoticed until it's too late. Understanding why wood dust is combustible is crucial for ensuring safety in industries that handle this material.

What Makes Wood Dust Combustible

Wood dust becomes combustible due to its fine particles that can easily ignite when suspended in air. When these particles reach a certain concentration, they create an explosive atmosphere, similar to the risks posed by combustible metals like aluminum and magnesium. Additionally, the presence of volatile organic compounds (VOCs) in some types of wood further enhances its flammability.

Industries at Risk: Furniture and Construction

The furniture and construction industries are particularly susceptible to the dangers of wood dust. In furniture manufacturing, processes like sanding and cutting generate significant amounts of fine wood particles that can accumulate quickly. Similarly, construction sites produce substantial wood waste; if not managed properly, this can lead to hazardous conditions comparable to those involving combustible metals.

Best Practices for Dust Collection

To mitigate the risks associated with wood dust, implementing effective dust collection systems is essential. Regularly scheduled cleanings and using high-efficiency particulate air (HEPA) filters can significantly reduce the amount of airborne dust present in facilities. Moreover, educating employees about proper handling techniques and maintaining equipment will help keep workplaces safe from both wood dust hazards and those posed by combustible metals.

The Role of NAROO in Dust Management

When it comes to managing combustible dust, particularly from combustible metals, NAROO stands out with its innovative solutions tailored for various industries. Their approach integrates advanced technology and effective design to mitigate dust-related hazards effectively. By focusing on the unique properties of different combustible metals, NAROO ensures that their systems are not just efficient but also compliant with safety standards.

NAROO's Innovative Solutions

NAROO has developed a range of cutting-edge dust collection systems specifically designed to handle the challenges posed by combustible metals like aluminum and magnesium. Their equipment features high-efficiency filters and explosion-proof designs that significantly reduce the risk of ignition from accumulated dust. Additionally, these solutions are equipped with smart monitoring systems that provide real-time data on dust levels, allowing facilities to maintain optimal safety standards.

Case Studies of Successful Implementations

One notable case involved a manufacturing plant specializing in aluminum components that faced significant risks from combustible metal dust accumulation. After implementing NAROO's tailored dust collection system, the facility reported a 75% reduction in airborne particulate matter and a marked improvement in overall workplace safety. Another example is a woodworking company that integrated NAROO’s solutions for wood dust management, which not only enhanced their compliance with OSHA regulations but also improved employee health outcomes.

Environmental Benefits of Effective Dust Removal

Effective removal of combustible metals and wood dust doesn't just enhance safety; it also offers substantial environmental benefits. By minimizing airborne pollutants, companies can contribute to cleaner air quality both inside and outside their facilities, promoting better health for employees and surrounding communities alike. Furthermore, efficient dust management systems can lead to reduced waste generation by capturing reusable materials from the production process.

Identifying Combustible Dust in Your Facility

Identifying combustible dust in your facility is crucial for maintaining a safe working environment. Dust, especially from combustible metals, can pose significant risks if not properly managed. Understanding how to conduct a thorough analysis and recognize the signs of dust accumulation can help you mitigate these hazards effectively.

Conducting a Dust Hazard Analysis

A Dust Hazard Analysis (DHA) is your first line of defense against combustible metals and other hazardous materials lurking in your facility. This systematic approach involves identifying potential sources of dust generation, assessing the properties of the dust, and evaluating the effectiveness of existing control measures. Engaging a qualified team to perform this analysis ensures that you cover all bases and can tailor solutions to fit your specific operational needs.

During the DHA, it’s important to document findings meticulously, noting areas where combustible metals are likely to accumulate, such as machinery zones or storage areas. This documentation serves as a foundation for developing an action plan that addresses any identified risks associated with combustible dust. Remember, regular reviews and updates to this analysis are essential as processes and materials change over time.

Signs of Combustible Dust Accumulation

Recognizing the signs of combustible dust accumulation is vital for preventing catastrophic events in your facility. Look out for visible layers of dust on surfaces like machinery, floors, or ledges; this is often an indication that you may have a problem on your hands with combustible metals or other materials. Additionally, pay attention to changes in equipment performance—if machines seem to be running less efficiently or overheating more frequently, it could be due to excessive dust buildup.

Another red flag is when employees report respiratory issues or other health concerns related to air quality; this could signal hidden dangers from airborne particles including those from combustible metals. Regular inspections should become part of your routine operations—don’t wait until there’s a visible issue before taking action! By fostering an environment where safety concerns are openly discussed and addressed promptly, you create a culture that prioritizes hazard awareness.

Resources for Assessment

To assist in identifying and managing combustible dust risks effectively, several resources are available at your disposal. The National Fire Protection Association (NFPA) provides guidelines specifically addressing combustible metals and their management within various industries. In addition to NFPA standards, OSHA offers valuable resources that outline compliance requirements related to workplace safety concerning hazardous materials.

Investing time into training employees on recognizing potential hazards associated with combustible dust will go a long way toward creating a safer work environment overall. Online tools such as risk assessment checklists can streamline the evaluation process while ensuring no critical details slip through the cracks during assessments. By leveraging these resources effectively, you’ll enhance both safety protocols and employee awareness regarding the dangers posed by combustibles in their daily tasks.

Compliance and Safety Standards

When it comes to managing combustible dust, compliance with safety standards is not just a box to check; it's a necessity for protecting lives and property. The National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA) have established guidelines that provide a framework for identifying, assessing, and mitigating the risks associated with combustible metals. Understanding these standards is crucial for any facility handling materials that can ignite under certain conditions.

Overview of NFPA and OSHA Guidelines

The NFPA has specific codes, such as NFPA 652, which outlines the fundamental requirements for managing combustible dust in various industries. OSHA complements these regulations by enforcing workplace safety standards designed to minimize hazards from combustible metals through proper ventilation, housekeeping, and equipment maintenance practices. Together, these guidelines create a comprehensive approach that encourages facilities to proactively address the dangers posed by combustible dust.

How to Achieve Compliance

Achieving compliance with NFPA and OSHA guidelines involves several key steps: conducting regular hazard assessments, implementing effective dust collection systems, and providing employee training on safe practices. Facilities must also maintain thorough documentation of their dust management processes to demonstrate adherence during inspections or audits. By prioritizing compliance measures focused on combustible metals, organizations can significantly reduce their risk of accidents while fostering a culture of safety.

The Benefits of a Robust Dust Collection System

Investing in a robust dust collection system offers numerous benefits beyond mere compliance; it enhances workplace safety while improving operational efficiency. An effective system captures airborne particles before they settle into hazardous piles of combustible metals or wood dust, minimizing fire risks significantly. Moreover, maintaining clean workspaces can lead to increased productivity as employees can focus on their tasks without worrying about potential dangers lurking in the dust.

Conclusion

In conclusion, understanding the risks associated with combustible dust, especially combustible metals, is crucial for maintaining safety in various industries. The potential hazards posed by these materials can lead to catastrophic events if not properly managed. By implementing effective dust collection systems and adhering to safety standards, organizations can significantly mitigate these risks.

Key Takeaways on Combustible Dust

Combustible dust, including combustible metals like aluminum and magnesium, presents a serious threat in many workplaces. Awareness of the specific characteristics and dangers associated with these materials is essential for preventing accidents. Regular inspections and maintenance of dust collection systems are vital to ensure that facilities remain compliant and safe from the risks posed by combustible dust.

Enhancing Safety Through Awareness

Enhancing safety in facilities that handle combustible metals requires ongoing education and training for employees on the hazards of dust accumulation. By fostering a culture of awareness around combustible dust risks, companies can empower their workforce to take proactive measures in identifying potential hazards. This vigilance not only protects employees but also helps maintain compliance with safety regulations.

The Future of Dust Collection Technology

The future of dust collection technology looks promising as innovations continue to emerge to tackle the challenges posed by combustible metals and other hazardous materials. Advanced filtration systems, automated monitoring technologies, and eco-friendly solutions are paving the way for safer work environments. As industries evolve, investing in state-of-the-art dust management solutions will be paramount for ensuring long-term safety and sustainability.