Introduction

In the modern industrial landscape, the risks associated with combustible dust are often underestimated, leading to potentially catastrophic consequences. Understanding these hazards is essential for maintaining workplace safety and compliance with regulations. The Occupational Safety and Health Administration (OSHA) has established guidelines to mitigate these risks, emphasizing the importance of effective dust control strategies across various industries.

Understanding Combustible Dust Hazards

Combustible dust hazards arise from fine particles that can ignite under certain conditions, leading to explosions or fires. Materials like aluminum dust, wood flour, and sugar can create a perilous environment when accumulated in sufficient quantities. Recognizing the characteristics of combustible dust is crucial for implementing proper safety measures, including using explosion-proof dust collectors and ensuring that any dust collector baghouse is regularly maintained.

The Importance of OSHA Regulations

OSHA's regulations regarding combustible dust are designed to protect workers from the serious dangers posed by these materials. Compliance with OSHA combustible dust standards not only safeguards employees but also helps businesses avoid hefty fines and legal repercussions. By adhering to OSHA construction dust control regulations, companies can establish safer work environments while enhancing their operational efficiency through effective risk management.

Combustible Dust in Various Industries

From food processing plants to metal fabrication facilities, combustible dust is a concern across multiple sectors. Industries handling materials like aluminum dust or organic substances must be particularly vigilant in managing their specific risks associated with combustion. Implementing robust systems such as high-pressure dust collectors or strategically placing a dust collector outside can significantly reduce the likelihood of hazardous incidents while promoting a culture of safety within organizations.

What is Combustible Dust?

When we talk about combustible dust, we’re delving into a potentially explosive topic—literally! This fine particulate matter can ignite under the right conditions, leading to catastrophic explosions and fires. Understanding its definition and characteristics is crucial for maintaining safety in various industries.

Definition and Characteristics

Combustible dust refers to any finely divided solid material that can catch fire and explode when suspended in air. This includes a wide range of substances such as metal powders, wood particles, and agricultural grains. The key characteristic that makes dust combustible is its particle size; generally, particles smaller than 420 microns pose the highest risk due to their increased surface area-to-volume ratio, which enhances combustion potential.

Common Sources of Combustible Dust

You might be surprised at just how many everyday materials can create combustible dust! Industries like food processing, woodworking, pharmaceuticals, and metal fabrication often generate this hazardous byproduct. For instance, aluminum dust from machining processes or flour dust from milling operations are common sources that require diligent management under OSHA combustible dust regulations to ensure workplace safety.

The Science of Dust Combustion

The science behind dust combustion is fascinating yet alarming. When combustible dust particles are dispersed in the air and exposed to an ignition source—such as a spark or flame—they can ignite rapidly. This rapid combustion leads to an explosion if the conditions are right; factors like particle size, concentration in the air, and even humidity levels play crucial roles in determining whether an explosion will occur.

Health and Safety Risks

Understanding the health and safety risks associated with combustible dust is crucial for preventing catastrophic incidents in various industries. The potential for explosions and fires poses significant threats not only to property but also to the lives of workers. Moreover, long-term exposure to certain types of dust can lead to serious health complications, making it essential for companies to adhere to OSHA combustible dust regulations.

Explosions and Fire Hazards

Explosions caused by combustible dust can be devastating, leading to loss of life, injuries, and extensive property damage. Industries that handle materials such as aluminum dust are particularly vulnerable; a small spark can ignite a massive explosion if proper precautions aren't taken. Implementing an explosion-proof dust collector is vital in mitigating these risks by capturing dust before it has the chance to ignite.

In addition, facilities must consider where they place their dust collector outside or inside their operations. An improperly located high pressure dust collector may not effectively contain combustible particles, increasing the risk of an explosive environment. Regular maintenance and inspections are necessary to ensure these systems function correctly and remain compliant with OSHA standards.

Long-Term Health Effects

The long-term health effects of exposure to combustible dust can be severe and often go unnoticed until it's too late. Chronic inhalation of fine particles can lead to respiratory issues, cardiovascular diseases, and even cancers over time—conditions that could have been prevented with adequate safety measures in place. For instance, workers exposed to aluminum dust without proper protective equipment may suffer from lung diseases that significantly impair their quality of life.

Moreover, many workers may not realize they're at risk until symptoms arise years later; hence proactive measures are critical in maintaining workplace safety. Ensuring compliance with OSHA construction dust control regulations helps protect employees from these harmful effects while fostering a culture of safety within organizations. Employers should prioritize regular training sessions on recognizing hazards associated with combustible dust exposure.

OSHA’s Role in Combustible Dust Safety

OSHA plays a pivotal role in setting guidelines for managing combustible dust hazards across various industries. Their regulations outline specific requirements for identifying hazardous materials like aluminum dust and implementing effective control measures such as using specialized high pressure dust collectors or explosion-proof systems. By adhering strictly to OSHA's guidelines regarding combustibility risks, companies create safer working environments that minimize potential disasters.

Furthermore, OSHA provides resources aimed at educating employers about best practices for managing combustible substances effectively—not just focusing on compliance but also fostering a proactive approach towards safety culture within organizations. Companies must stay updated on evolving OSHA standards related to combustible dust management so they can adapt their practices accordingly—after all, staying ahead means ensuring everyone goes home safe at the end of the day.

Regulations and Standards

The landscape of regulations and standards surrounding combustible dust is critical for ensuring workplace safety. OSHA has established specific guidelines to mitigate the risks associated with combustible dust, particularly in industries that handle materials like aluminum dust. Understanding these standards is essential for companies aiming to comply with safety regulations while protecting their employees.

Overview of OSHA Combustible Dust Standards

OSHA's combustible dust standards focus on identifying and controlling hazards related to combustible dust in various industries. These regulations encompass a wide range of materials, including metals, wood, and organic substances that can create explosive atmospheres if not properly managed. By establishing clear guidelines, OSHA aims to minimize the risk of explosions and fires linked to combustible dust accumulation.

In addition to general industry standards, OSHA also addresses construction-specific regulations tailored for environments where construction dust control is paramount. Employers are required to assess their workplaces for potential combustible dust hazards and implement appropriate control measures accordingly. This proactive approach helps ensure that workers are safeguarded from the inherent dangers posed by inadequate dust management.

Key Compliance Requirements

To comply with OSHA's combustible dust standards, companies must first conduct thorough hazard assessments in their facilities. This involves identifying areas where combustible dust may accumulate and evaluating the potential risks associated with those materials—especially when dealing with fine particles like aluminum dust. Once hazards are identified, employers must implement effective control measures such as maintaining clean workspaces and utilizing explosion-proof equipment like high-pressure dust collectors.

Additionally, training employees on safe handling practices is crucial for compliance with OSHA construction dust control regulations. Workers should be educated about the risks associated with combustible dust and trained on how to recognize hazardous situations effectively. Regular inspections of equipment such as baghouses or outside-mounted dust collectors also play a vital role in maintaining compliance while ensuring ongoing safety.

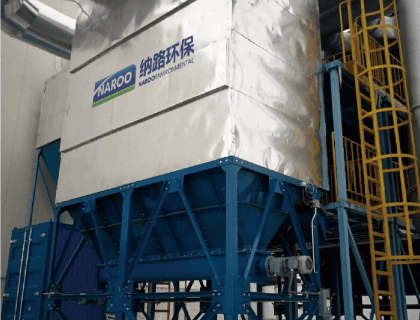

How NAROO Aligns with OSHA Guidelines

NAROO takes its commitment to workplace safety seriously by aligning its practices with OSHA’s guidelines concerning combustible dust management. The company provides innovative solutions designed specifically for industries at risk of combustion hazards, focusing on products like explosion-proof dust collectors that meet stringent safety requirements. By integrating advanced technology into their systems—such as high-pressure options tailored for demanding environments—NAROO ensures effective containment of potentially hazardous materials.

Moreover, NAROO emphasizes education as part of its strategy; they offer training programs that help organizations understand OSHA's requirements around managing aluminum dust effectively while using proper equipment like baghouses or outdoor collectors efficiently. This alignment not only promotes compliance but also fosters a culture of safety within workplaces prone to combustible hazards.

In summary, understanding the regulatory framework set forth by OSHA is essential for any organization dealing with combustible materials—especially those handling fine particles like aluminum or working in construction settings where effective control measures are paramount.

Effective Dust Management Strategies

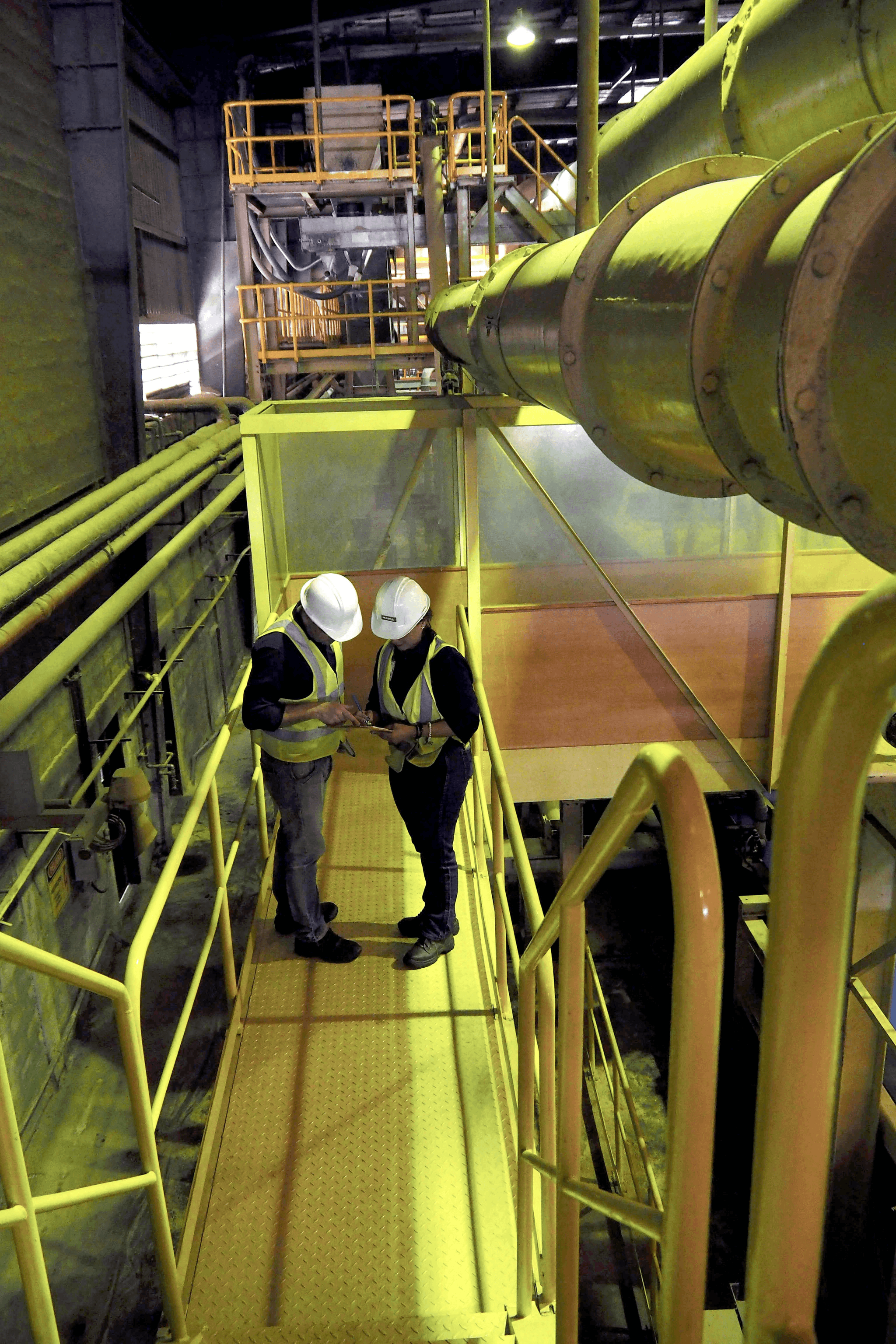

In the world of combustible dust, effective management strategies are crucial to prevent hazardous situations and ensure workplace safety. A proactive approach includes identifying high-risk areas, implementing robust control measures, and utilizing advanced solutions tailored to specific industry needs. By adhering to OSHA combustible dust guidelines, organizations can significantly reduce the risk of explosions and maintain a safer work environment.

Identifying High-Risk Areas

Identifying high-risk areas is the first step in managing combustible dust effectively. Facilities should conduct thorough assessments to pinpoint locations where dust accumulates, especially in industries handling materials like aluminum dust or wood particles. Areas like production floors, storage spaces, and equipment zones often harbor dangerous levels of dust that can lead to catastrophic events if not addressed.

Using tools such as thermal imaging cameras and air quality monitors can help detect hidden dust deposits that may not be visible during regular inspections. Furthermore, understanding the specific characteristics of different types of combustible dust is essential; for instance, aluminum dust requires different handling procedures compared to organic materials. By pinpointing these high-risk areas accurately, businesses can take targeted actions to mitigate potential hazards.

Implementing Control Measures

Once high-risk areas are identified, implementing control measures becomes paramount in ensuring compliance with OSHA construction dust control regulations. Effective solutions include installing explosion-proof dust collectors and utilizing baghouse systems designed specifically for managing fine particulate matter safely. These systems not only capture hazardous materials but also prevent them from accumulating in critical areas where they could ignite.

Regular maintenance of these systems is equally important; a well-maintained high-pressure dust collector ensures optimal performance and reduces the likelihood of malfunctions that could lead to explosive conditions. Additionally, training employees on proper housekeeping practices will help maintain clean workspaces free from excessive buildup of combustible materials like aluminum or wood dust. By establishing a culture of safety through diligent control measures, organizations can significantly enhance their overall risk management strategy.

Advanced Solutions from NAROO

NAROO offers cutting-edge solutions tailored specifically for effective combustible dust management that align with OSHA standards while addressing unique industry challenges. Their innovative products include state-of-the-art explosion-proof dust collectors designed for various industrial applications—ensuring safety without compromising productivity. With advanced filtration systems integrated into their equipment, NAROO helps companies efficiently manage both visible and invisible contaminants.

Moreover, NAROO provides customizable options for outdoor installations of their powerful dust collection units—ensuring that facilities can adapt based on space constraints or operational requirements without sacrificing safety standards set forth by OSHA combustible dust regulations. Their commitment extends beyond just providing equipment; they offer comprehensive support services including training on best practices for maintaining a safe working environment against explosive risks associated with combustible materials like aluminum or other fine particulates.

Case Studies and Real-World Examples

When it comes to understanding the dangers of combustible dust, real-world incidents provide invaluable lessons. Various industries have faced devastating explosions due to improper handling and management of combustible dust. These case studies not only highlight the risks but also underscore the importance of adhering to OSHA combustible dust regulations.

Industrial Incidents Involving Combustible Dust

One notable incident occurred at a food processing facility where flour dust accumulated in hidden areas, resulting in a catastrophic explosion that injured several workers. The lack of an explosion-proof dust collector contributed significantly to the disaster, as airborne particles ignited due to static electricity. Similarly, an aluminum dust explosion at a manufacturing plant demonstrated how even small amounts of fine particles can lead to massive destruction if not properly controlled with effective systems like high-pressure dust collectors.

Another alarming case involved a woodworking shop where sawdust accumulation led to an explosive fireball that engulfed the facility in seconds. The absence of adequate ventilation and failure to implement OSHA construction dust control regulations exacerbated the situation, showcasing how critical proper management is in preventing such tragedies. These incidents serve as stark reminders that neglecting combustible dust safety can have dire consequences for both personnel and property.

Lessons Learned from Past Events

From these industrial incidents, several key lessons emerge about managing combustible dust hazards effectively. First and foremost, regular inspections are essential; identifying high-risk areas before they become problematic is crucial for safety compliance with OSHA regulations. Additionally, investing in reliable equipment such as a properly designed dust collector baghouse can mitigate risks significantly by capturing hazardous particles before they have a chance to ignite.

Moreover, training employees on best practices for managing combustible materials cannot be overstated; awareness is half the battle when it comes to preventing accidents involving aluminum dust or other flammable substances. Lastly, companies must prioritize creating comprehensive emergency response plans tailored specifically for scenarios involving explosive environments created by accumulated combustible dust—because being prepared is always better than being sorry.

Success Stories in Combustible Dust Management

On a more positive note, there are numerous success stories demonstrating effective strategies for managing combustible dust hazards successfully. One manufacturing plant implemented advanced solutions from NAROO by installing state-of-the-art explosion-proof dust collectors that effectively minimized airborne particles while complying with OSHA standards. This proactive approach not only improved workplace safety but also enhanced overall operational efficiency—proving that investment pays off!

Another company specializing in metal fabrication adopted innovative control measures including outdoor placement of their high-pressure dust collector systems which significantly reduced indoor contamination levels while ensuring compliance with OSHA construction dust control regulations. Their commitment paid dividends as they reported zero incidents related to combustible dust since implementing these changes—a true testament that diligence leads directly toward safer work environments.

In conclusion, these cases illustrate both the perils associated with inadequate management of combustible materials and the triumphs achievable through diligent adherence to established safety protocols like those outlined by OSHA regarding combustible dust hazards.

Conclusion

In conclusion, the landscape of combustible dust safety is evolving, driven by increased awareness and stringent regulations. As industries recognize the potential hazards associated with combustible dust, adherence to OSHA combustible dust standards becomes paramount. The future promises not only enhanced safety protocols but also innovative technologies that will redefine how we approach dust management.

The Future of Combustible Dust Safety

Looking ahead, the future of combustible dust safety is likely to be shaped by ongoing advancements in regulation and technology. With OSHA construction dust control regulations becoming more rigorous, businesses will need to adapt quickly to comply with these standards. This shift will foster a culture of safety that prioritizes employee well-being and minimizes risks associated with aluminum dust and other hazardous materials.

Innovations in Dust Control Technology

Innovations in dust control technology are paving the way for safer industrial environments. For instance, explosion proof dust collectors are becoming essential tools for managing combustible dust effectively while ensuring compliance with OSHA guidelines. Additionally, high pressure dust collectors provide enhanced filtration capabilities that can significantly reduce airborne particles, making workplaces safer for everyone involved.

NAROO’s Commitment to a Safer Environment

NAROO remains steadfast in its commitment to a safer environment through proactive measures and cutting-edge solutions for managing combustible dust risks. By aligning our products with OSHA combustible dust standards, we ensure that our clients have access to effective tools like the robust dust collector baghouse and outdoor systems designed specifically for high-risk areas. Together, we can create workplaces where safety is not just a priority but an ingrained value.