Introduction

In the world of industrial operations, managing dust and particulate matter is not just a matter of cleanliness; it’s essential for safety and efficiency. This is where the cartridge dust collector filter comes into play, serving as a pivotal component in modern dust collection systems. With their ability to capture fine particles effectively, these filters are transforming dust collection industrial practices, ensuring compliance with health regulations while enhancing productivity.

The Importance of Cartridge Dust Collector Filters

Cartridge dust collector filters are vital in maintaining air quality within industrial environments. Unlike traditional filter bag dust collectors, cartridge filters provide superior filtration efficiency and require less space for installation. Their compact design allows for easier maintenance and replacement, making them an indispensable asset in any facility focused on optimizing their dust collection systems.

Benefits of Effective Dust Collection Systems

Implementing an effective dust collection system using industrial cartridge filters offers numerous benefits beyond just cleaner air. These systems help reduce workplace hazards by minimizing airborne contaminants that can lead to respiratory issues among workers. Moreover, effective filtration translates into lower operational costs by reducing equipment wear and tear while increasing overall system efficiency—making it a win-win for both employees and employers.

How to Choose the Right Industrial Filters

Choosing the right industrial filters is crucial for achieving optimal performance in your dust collection system. Factors such as particle size, airflow requirements, and specific industry needs should guide your selection process when considering a cartridge with filter options or even specialty filters designed for unique applications. By understanding these elements and consulting with experts, you can ensure that your facility is equipped with the most suitable cartridge dust collector filter to meet its operational demands.

Understanding Cartridge Dust Collector Filters

Cartridge dust collector filters are a vital component of effective dust collection systems in industrial settings. These filters are designed to capture and contain airborne particles generated during manufacturing processes, ensuring cleaner air and compliance with health regulations. By understanding how cartridge filters work and their advantages over traditional systems, businesses can make informed decisions about their dust collection strategies.

What Are Cartridge Filters?

Cartridge filters are cylindrical filtration devices that utilize a pleated design to increase surface area, enhancing their dust-holding capacity. Unlike traditional filter bag dust collectors, which use larger fabric bags to trap particles, cartridge filters provide a more compact solution without compromising performance. This design allows for efficient airflow while effectively capturing fine particulates common in various industrial applications.

How They Operate in Dust Collection

In a typical dust collection industrial setup, the cartridge filter is positioned within the collector unit where it plays a crucial role in separating dust from the air stream. As contaminated air passes through the cartridge with filter media, particles adhere to the surface of the filter while clean air is released back into the environment. Periodic cleaning methods such as pulse jet or shaker systems help maintain optimal performance by dislodging accumulated dust from the filter surface.

Advantages Over Traditional Filter Bag Dust Collectors

One of the primary advantages of using industrial cartridge filters over traditional filter bag dust collectors is their superior efficiency and effectiveness at capturing smaller particles. Cartridge filters typically require less space due to their compact design, making them ideal for facilities with limited room for equipment installation. Additionally, they often have lower maintenance costs since they can be cleaned and reused multiple times before needing replacement, ultimately saving businesses money over time on both labor and materials associated with maintaining their filtration systems.

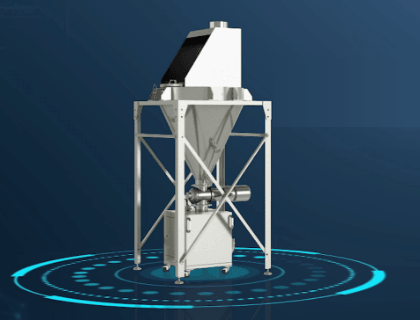

NAROO: A Leader in Dust Collection Solutions

With years of experience under its belt, the company has honed its expertise in delivering high-quality cartridge dust collector filters that cater to various industrial needs. Their commitment to innovation and customer satisfaction positions them as a trusted partner for businesses looking to enhance their filtration systems.

Overview of NAROO’s Expertise

NAROO has established itself as a leader in the field of industrial filters, specializing in cartridge dust collector filter technology. Their team comprises seasoned professionals who understand the intricacies of dust collection systems and are dedicated to providing tailored solutions for diverse industries. By focusing on quality and performance, NAROO ensures that their customers receive filters industrial products that not only meet but exceed expectations.

Innovative Technologies in Cartridge Filters

Innovation is at the heart of NAROO's approach to developing advanced cartridge with filter technologies. They leverage cutting-edge materials and engineering techniques to create industrial cartridge filters that offer superior filtration efficiency and durability compared to traditional filter bag dust collectors. With features like enhanced surface area and optimized airflow design, these innovative filters help businesses achieve cleaner environments while reducing maintenance costs.

Case Studies of Successful Implementations

NAROO’s track record speaks volumes about their expertise in implementing effective dust collection solutions across various sectors. For instance, one notable case involved a manufacturing facility struggling with excessive airborne particulates; after installing NAROO's specialized cartridge dust collector filter system, they reported a 95% reduction in particulate matter within just weeks. Another example includes an automotive plant that integrated NAROO's innovative filtration technology into its existing setup, resulting in significant operational efficiencies and compliance with environmental regulations.

Types of Cartridge Filters Available

When it comes to cartridge dust collector filters, choosing the right type can significantly impact the efficiency of your dust collection industrial systems. Understanding the various options available is essential in ensuring optimal performance and longevity. This section will delve into pleated cartridge filters, specialty filters for specific industries, and how to select the best filter for your needs.

Pleated Cartridge Filters vs. Standard Cartridges

Pleated cartridge filters offer a larger surface area compared to standard cartridges, making them a popular choice in many industrial applications. This increased surface area allows for more efficient dust capture, reducing the frequency of filter changes and maintenance costs associated with traditional filter bag dust collectors. Furthermore, pleated cartridges typically have a higher dirt-holding capacity, meaning they can handle heavier loads without compromising airflow or performance.

On the other hand, standard cartridges may be suitable for less demanding environments where dust levels are manageable. They often come at a lower initial cost but can lead to increased operational expenses over time due to more frequent replacements and reduced efficiency. Ultimately, while both types serve their purpose, pleated cartridge filters generally provide better value in high-performance settings.

Specialty Filters for Specific Industries

Different industries have unique requirements when it comes to filtration needs; hence specialty filters are designed to cater specifically to these demands. For instance, food processing facilities may require HEPA-rated cartridge dust collector filters that meet stringent hygiene standards while effectively capturing fine particles and allergens. Similarly, pharmaceutical manufacturers often utilize specialized industrial cartridge filters engineered to trap contaminants without risking product integrity.

Additionally, industries like woodworking or metal fabrication benefit from filters designed specifically for fine wood dust or metal shavings—ensuring compliance with safety regulations while enhancing workplace air quality. Choosing these tailored solutions not only improves operational efficiency but also helps maintain industry-specific compliance standards that protect both workers and products alike.

Choosing the Right Filter for Your Needs

Selecting the appropriate filter from an array of industrial filters can feel overwhelming; however, there are key factors that simplify this decision-making process. First and foremost is understanding your specific application: what type of materials are being processed? What is the volume of dust generated? Answering these questions helps narrow down options between pleated cartridge filters and specialty designs tailored for your industry.

Next is considering aspects such as filter media composition—some materials may offer better chemical resistance or higher filtration efficiencies than others based on your operational environment. Additionally, think about maintenance requirements; some cartridges may require more frequent replacement or cleaning than others which could influence long-term costs associated with your dust collection system.

In summary, taking time to evaluate your needs against available options will lead you toward selecting a cartridge with filter that maximizes performance while minimizing costs—ultimately enhancing your overall productivity in any industrial setting.

Maintenance Tips for Industrial Cartridge Filters

Maintaining your cartridge dust collector filter is crucial for optimal performance and longevity. Regular upkeep not only enhances the efficiency of your dust collection industrial system but also saves you money on replacements and repairs. By following a few simple maintenance tips, you can ensure that your industrial filters remain in top-notch condition.

Regular Inspection and Cleaning Routines

To keep your cartridge with filter functioning effectively, establish a routine inspection schedule. Regularly checking for dust accumulation and wear will help you catch potential issues before they escalate. Cleaning routines can include backwashing or using compressed air to dislodge trapped particles, ensuring your industrial cartridge filters operate at peak efficiency.

Additionally, monitor the pressure drop across the filter; an increase may indicate that it's time for a thorough cleaning or replacement. Make it a habit to inspect seals and gaskets as well, as these components are essential for maintaining an airtight system. By staying proactive with inspections and cleaning, you'll extend the life of your cartridge dust collector filter significantly.

Common Signs Your Filter Needs Replacement

Knowing when to replace your cartridge dust collector filter is vital for maintaining optimal performance in any dust collection industrial application. Some common signs include excessive pressure drops, visible damage to the filter media, or an unusual increase in emissions from the exhaust system. If you notice these symptoms, it’s likely time to consider replacing your filters industrial.

Another telltale sign is a sudden spike in energy costs; if your system is working harder than usual due to clogged filters, it can lead to increased operational expenses. Additionally, if you find yourself cleaning the filters more frequently without substantial improvement in performance, this could indicate that they have reached their end of life cycle. Recognizing these signs early will save you from costly downtime and ensure efficient operation.

Cost-Effective Strategies for Longevity

Investing in proper maintenance strategies can significantly enhance the longevity of your industrial cartridge filters while keeping costs down over time. One effective approach is implementing a preventive maintenance program that includes regular inspections and timely replacements based on usage patterns rather than waiting until problems arise with your cartridge with filter systems.

Utilizing high-quality pre-filters can also help extend the life of your primary cartridges by capturing larger particles before they reach the main filtration stage—this reduces strain on both types of filters used in dust collection systems like traditional filter bag dust collectors as well as modern cartridges. Lastly, training staff on proper handling procedures during installation or replacement can prevent damage caused by mishandling or improper sealing techniques.

By adopting these cost-effective strategies, you'll not only prolong the lifespan of your equipment but also maintain efficiency in managing airborne particulates effectively throughout various industries.

Enhancing Efficiency with Advanced Filtration Technology

In the ever-evolving world of dust collection industrial solutions, enhancing efficiency is paramount. Advanced filtration technology, particularly in cartridge dust collector filters, plays a significant role in optimizing performance and reducing operational costs. As industries strive for cleaner air and better compliance with environmental regulations, integrating smart technologies becomes essential.

Role of Smart Sensors in Monitoring Performance

Smart sensors are revolutionizing how we monitor the efficacy of industrial filters. These devices provide real-time data on filter performance, allowing operators to identify issues before they escalate into costly problems. By integrating smart sensors into cartridge dust collector filter systems, businesses can ensure optimal airflow and maintain peak efficiency throughout the lifespan of their industrial cartridge filters.

Moreover, these sensors can alert users to changes in pressure differentials or airflow patterns that indicate when maintenance is required. This proactive approach not only extends the life of your cartridge with filter systems but also enhances overall workplace safety by minimizing airborne contaminants. With smart sensors at play, companies can move from reactive to proactive maintenance strategies, ultimately saving time and money.

The Future of Industrial Cartridge Filters

The future looks bright for industrial cartridge filters as innovations continue to emerge in filtration technology. Manufacturers are focusing on creating more durable materials that enhance filtration efficiency while reducing resistance to airflow—key factors for any effective dust collection system. As industries become more aware of sustainability and environmental impacts, we can expect a surge in demand for eco-friendly filters industrial solutions.

Additionally, advancements such as nanofiber technology promise even finer filtration capabilities without sacrificing airflow rates—perfect for applications where particulate matter is particularly hazardous. The integration of artificial intelligence (AI) will also play a crucial role in predicting filter lifespan and optimizing cleaning cycles based on real-time data analytics from smart sensors installed within the systems. This combination ensures that businesses remain compliant while maintaining operational excellence.

Integration with Existing Dust Collection Systems

Integrating advanced filtration technologies with existing dust collection systems doesn't have to be daunting; it can be quite seamless! Many modern cartridge dust collector filters are designed to fit into pre-existing setups without requiring extensive modifications or overhauls. This adaptability means that businesses can upgrade their current filter bag dust collector systems without incurring significant downtime or costs.

Furthermore, retrofitting existing units with advanced sensors or smarter control panels allows companies to gain insights into their operations like never before—leading to improved decision-making processes regarding maintenance schedules and filter replacements. By leveraging both new technologies and established systems effectively, organizations can achieve enhanced productivity levels while ensuring cleaner air quality throughout their facilities.

Conclusion

In wrapping up our exploration of cartridge dust collector filters, it's clear that effective dust collection systems are essential for maintaining a safe and efficient industrial environment. The right industrial filters not only enhance air quality but also improve operational efficiency, making them a smart investment for any facility. As we've seen, choosing the appropriate filter can significantly impact your dust collection industrial processes.

Key Takeaways in Dust Collection Systems

Cartridge filters offer superior filtration efficiency and require less maintenance than their bag counterparts, making them an attractive option for many industries. Additionally, regular inspection and timely replacement of industrial cartridge filters can lead to cost savings and prolonged equipment lifespan.

Future Trends in Cartridge Dust Collector Filters

The future of cartridge dust collector filters is looking bright with advancements in technology driving innovation in filtration solutions. Smart sensors are becoming increasingly integrated into these systems, allowing for real-time monitoring of filter performance and air quality metrics. As industries continue to prioritize sustainability and efficiency, we can expect more specialized industrial filters tailored to specific applications, further enhancing the effectiveness of dust collection systems.

Why NAROO is Your Go-To for Filters Industrial Solutions

NAROO stands out as a leader in providing top-notch filtration solutions tailored to meet the diverse needs of various industries. Their commitment to innovation ensures that you receive cutting-edge cartridge with filter technology designed for optimal performance and reliability.