Introduction

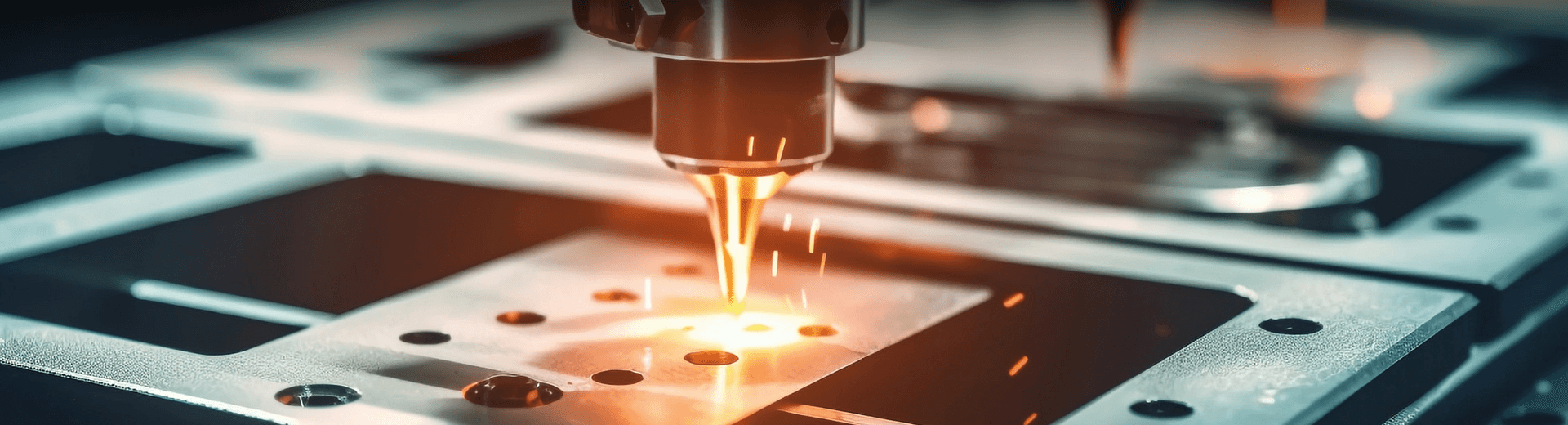

In the world of laser cutting, dust collection is not just an afterthought; it’s a crucial aspect that can significantly impact both efficiency and safety. Understanding the importance of dust collection systems is essential for maintaining optimal performance while ensuring a safe working environment. With various types of dust collection systems available, from centralized to localized solutions, selecting the right one can make all the difference in managing harmful particles.

Understanding the Importance of Dust Collection

Dust generated during laser cutting processes can lead to a myriad of complications if not properly managed. Not only does it affect the quality of cuts and equipment longevity, but it also poses significant health risks to operators. The right dust collection system helps in mitigating these issues, ensuring that workspaces remain clean and safe while enhancing productivity.

How Dust Affects Laser Cutting Processes

When discussing whether is laser dust harmful, it's important to note that even minimal amounts can interfere with precision cutting and lead to expensive reworks or equipment failure. Accumulations of aluminum dust hazards are particularly concerning as they can ignite under certain conditions, posing fire risks alongside health concerns. Properly addressing these challenges through effective dust management strategies is vital for maintaining high standards in laser cutting operations.

Addressing Health Risks of Laser Dust

Operators must be aware that exposure to laser-generated dust can have serious health implications over time; hence understanding whether is laser dust harmful should be a priority for every workplace. This includes recognizing different types of dust generated during cutting processes—like aluminum dust extraction—which may require specialized handling techniques due to their unique properties and potential hazards. By investing in efficient dust collection systems and adhering to best practices for heavy equipment air filter cleaning, businesses can significantly reduce health risks associated with laser cutting environments.

The Hazards of Laser Dust

Laser cutting is an intricate process that creates not only precise designs but also a significant amount of dust. This dust, often overlooked, can pose serious hazards to operators and the environment. Understanding whether laser dust is harmful is crucial for maintaining a safe workplace.

Is Laser Dust Harmful to Operators?

The answer to whether laser dust is harmful hinges on various factors, including the type of material being cut and the effectiveness of the dust collection systems in place. When operators inhale fine particles generated during laser cutting, they may experience respiratory issues or other health complications over time. Therefore, investing in a robust centralized dust collection system can significantly mitigate these risks by capturing harmful particles before they become airborne.

In addition to respiratory concerns, prolonged exposure to certain types of dust can lead to skin irritations and other allergic reactions. Operators should be aware that not all materials produce the same level of hazardous dust; thus, understanding specific risks associated with different materials is essential. Ultimately, ensuring a safe working environment involves both effective equipment and operator awareness about whether laser dust is harmful.

Aluminum Dust Hazards and Health Concerns

Aluminum dust hazards are particularly noteworthy in industries utilizing laser cutting technology for aluminum materials. When aluminum is cut or ground, it produces fine particles that can ignite easily if not properly managed—this makes aluminum dust extraction a critical aspect of safety protocols in any workshop dealing with this metal. Inhalation or skin contact with aluminum particulates could lead to serious health concerns such as lung disease or dermatitis.

Moreover, when discussing aluminum dust hazards, it's essential to consider how these particles interact with other substances present in the workshop environment. For example, mixing aluminum with certain chemicals may create explosive conditions if adequate precautions are not taken during heavy equipment air filter cleaning processes. Thus, understanding and managing these specific hazards becomes imperative for operators working with aluminum using laser cutting techniques.

Recognizing Types of Dust in Laser Cutting

Recognizing types of dust in laser cutting extends beyond simply identifying visible particles; it requires an understanding of their composition and potential effects on health and safety. Common types include metallic debris from steel or aluminum cuts as well as non-metallic particulates from plastics or wood materials—each presenting unique challenges for effective aerospace dust extraction strategies.

Different materials produce varying sizes and densities of particles which can affect how they are collected by different types of dust collection systems—be it centralized or localized systems designed for specific applications within a workshop setting. Understanding these distinctions allows operators to select appropriate filtering solutions tailored for their specific needs while ensuring compliance with industry regulations regarding health risks associated with airborne particulates.

An Overview of Dust Collection Systems

Dust collection systems play a vital role in ensuring a safe and efficient laser cutting environment. Understanding the various types of dust collection systems can significantly impact not only the quality of the cut but also the health of operators. With concerns around whether is laser dust harmful, it’s crucial to explore both centralized and localized solutions to effectively manage aluminum dust hazards.

Understanding Centralized Dust Collection Systems

Centralized dust collection systems are designed to serve multiple machines from a single location, creating an efficient network for handling various types of dust generated during operations. This system typically involves ductwork that connects individual workstations to a central collector, which captures and filters airborne particles before they can become a health hazard. While centralized systems can effectively manage large volumes of aluminum dust extraction, they may require significant initial investment and space.

The efficiency of centralized systems in dealing with heavy equipment air filter cleaning is notable; however, these setups can sometimes lead to longer distances for dust transport, which may reduce overall effectiveness if not properly designed. Operators need to ensure that their centralized system is well-maintained to prevent issues such as clogs or leaks that could exacerbate aluminum dust hazards. Ultimately, understanding how these systems operate is essential for maximizing safety and productivity in laser cutting environments.

Advantages of Localized Dust Collection Systems

Localized dust collection systems focus on capturing dust at its source, providing targeted solutions directly at individual workstations or machines. This approach minimizes the distance that airborne particles travel before being filtered out, making it particularly effective for managing specific types of dust generated during laser cutting processes. By addressing concerns about whether is laser dust harmful right at the source, localized systems contribute significantly to healthier working conditions.

One major advantage of localized systems is their ability to be installed with less complexity compared to centralized setups; they often require fewer resources and less space while still delivering effective results in aluminum dust extraction. Furthermore, localized units can be easily moved or adjusted as production needs change, offering flexibility that larger centralized options may lack. Overall, this adaptability makes them ideal for smaller workshops or facilities where space is at a premium.

Key Features of Effective Dust Extractors

When selecting an effective dust extractor for laser cutting operations, several key features should be considered to ensure optimal performance against both general and specific types of dust hazards like aluminum particles. First and foremost is airflow capacity: an extractor must have sufficient power to capture debris without becoming overwhelmed by high volumes produced during intense cutting sessions. Additionally, look for models equipped with HEPA filters or specialized filtration technology tailored specifically for capturing fine particulates.

Another important aspect involves ease of maintenance; heavy equipment air filter cleaning should be straightforward so operators can regularly check filters and replace them as needed without disrupting workflow excessively. Moreover, noise levels should also be taken into account since quieter models promote better working conditions without compromising on efficiency during operation—especially vital when considering long hours spent in proximity to machinery generating hazardous materials like aluminum dust.

Finally, consider any additional features such as automatic shutoff functions when no activity is detected or integrated monitoring systems that alert users about filter status—these innovations enhance usability while ensuring compliance with safety standards related to aerospace dust extraction requirements as well as general workplace regulations.

Top Dust Collection Solutions for Laser Cutting

In the realm of laser cutting, selecting the right dust collection system is crucial not just for efficiency, but also for health and safety. With various types of dust collection systems available, operators must navigate choices that best fit their specific needs. This section delves into some of the top solutions currently available on the market.

NAROO's Innovative Dust Collection Technology

NAROO has emerged as a frontrunner in developing advanced dust collection technology tailored specifically for laser cutting applications. Their systems are designed to effectively capture a wide variety of dust particles, including aluminum dust hazards that can pose serious health risks if left unchecked. By utilizing a centralized dust collection system, NAROO ensures that even the finest laser dust is efficiently extracted from the workspace, enhancing both safety and productivity.

One standout feature of NAROO's technology is its ability to adapt to different operational scales, making it suitable for everything from small workshops to large manufacturing plants. The integration of smart sensors allows for real-time monitoring and automatic adjustments based on workload demands. This innovation not only maximizes efficiency but also minimizes energy consumption—an essential consideration in today’s eco-conscious landscape.

Selecting the Right Equipment for Your Setup

Choosing the right equipment involves assessing various factors such as workspace size, type of materials processed, and specific health risks associated with laser cutting operations—like whether is laser dust harmful to operators in your environment? For instance, if you’re primarily working with aluminum materials, investing in specialized aluminium dust extraction systems will ensure you're adequately protected against potential health hazards linked to metal particulates.

Consideration should also be given to maintenance requirements; systems that facilitate easy heavy equipment air filter cleaning can save time and reduce downtime significantly over time. Additionally, understanding whether a localized or centralized approach suits your operation better will impact both performance and budget allocation dramatically. Remember: an informed choice today leads to safer work conditions tomorrow!

Maintaining Your Dust Collection System

Maintaining your dust collection system is crucial for ensuring safety and efficiency in laser cutting operations. Regular maintenance not only prolongs the life of your equipment but also minimizes the health risks associated with laser dust, including aluminum dust hazards. By understanding the importance of routine checks and proper cleaning techniques, you can optimize your centralized dust collection system or any other types of dust collection systems you may use.

Importance of Regular System Checks

Regular system checks are essential to ensure that your dust collection system operates at peak performance. Neglecting these checks can lead to a buildup of harmful materials, which raises the question: is laser dust harmful? Over time, accumulated aluminum dust can create a hazardous environment for operators and compromise the effectiveness of your equipment.

By conducting routine inspections, you can identify potential issues before they escalate into costly repairs or safety violations. Checking filters, ducts, and connections allows you to maintain airflow efficiency while reducing exposure to dangerous particles. Ultimately, consistent maintenance keeps both operators and machinery safe from the adverse effects associated with aluminum dust hazards.

Heavy Equipment Air Filter Cleaning Techniques

Cleaning heavy equipment air filters is a vital aspect of maintaining any effective dust extraction system. Filters are often the first line of defense against harmful particles; therefore, knowing how to clean them properly can extend their lifespan significantly. One recommended technique involves using compressed air to blow out trapped debris without damaging the filter itself.

Another method includes soaking reusable filters in warm soapy water followed by thorough rinsing and drying before reinstalling them in your centralized dust collection system or localized setups. Regularly scheduled cleaning ensures that air quality remains high while reducing wear on your equipment due to clogging from various types of dust generated during laser cutting processes.

Tips for Extending the Life of Your Dust Collector

To maximize the lifespan of your dust collector, consider implementing a few simple yet effective practices tailored for both centralized and localized systems. First off, avoid overloading your collector by adhering to recommended usage guidelines; this will help prevent unnecessary strain on motors and filters alike—keeping those pesky aluminum dust hazards at bay!

Moreover, invest in quality replacement parts when needed; opting for original manufacturer components ensures compatibility and reliability over time—especially important in aerospace applications where precision matters most in aerospace dust extraction efforts! Lastly, establish a regular maintenance schedule that incorporates thorough cleanings along with timely inspections—because an ounce of prevention truly is worth a pound (or more) when it comes down to protecting both operators' health and machinery longevity.

Aerospace Industry and Dust Extraction Requirements

The aerospace industry presents unique challenges when it comes to dust extraction, particularly due to the diverse materials used in manufacturing. From aluminum components to composite materials, the types of dust generated can vary significantly, each posing distinct hazards. Furthermore, the precision required in aerospace manufacturing means that even small amounts of dust can compromise quality, making effective dust collection systems essential.

Unique Challenges in Aerospace Dust Extraction

In aerospace manufacturing, operators often encounter various types of dust collection systems tailored to specific applications. The challenge lies in effectively managing aluminum dust hazards while ensuring compliance with stringent safety standards. Additionally, many processes produce fine particulate matter that can easily become airborne, necessitating advanced centralized dust collection systems designed for high efficiency.

The variability in materials also complicates matters; different substances may require specialized filtration methods to capture harmful particles effectively. For instance, is laser dust harmful? This question looms large as laser cutting operations generate fine debris that may contain toxic elements if not properly managed. Thus, a comprehensive understanding of aerospace dust extraction techniques is critical for maintaining a safe working environment.

Regulations for Dust Control in Aerospace Manufacturing

Regulatory bodies impose strict guidelines on dust control in aerospace manufacturing to protect workers and ensure product integrity. These regulations often specify acceptable levels of airborne contaminants and mandate the use of effective aluminum dust extraction systems to minimize exposure risks. Companies must stay informed about local and international standards related to heavy equipment air filter cleaning protocols as part of their compliance efforts.

Moreover, failure to adhere to these regulations can result in substantial fines or operational shutdowns, making it imperative for manufacturers to implement robust safety measures proactively. Regular audits and assessments are necessary not only for compliance but also for optimizing existing centralized dust collection systems or localized solutions based on the specific needs of their operations. By prioritizing adherence to these regulations, companies can foster a safer workplace while enhancing productivity.

Best Practices for Safe Dust Management

Effective management of aerospace dust extraction requires implementing best practices tailored specifically for this industry’s complexities. First and foremost is regular maintenance of heavy equipment air filter cleaning; filters should be checked frequently and replaced as needed to ensure optimal performance against aluminum dust hazards. Additionally, training employees on recognizing different types of dust generated during operations empowers them with knowledge about potential risks associated with is laser dust harmful?

Another key practice involves conducting routine risk assessments that evaluate existing processes and identify areas where improvements can be made regarding safety protocols or equipment upgrades—such as transitioning from outdated localized solutions to more efficient centralized systems when necessary. Finally, fostering an organizational culture focused on continuous improvement ensures that all employees are engaged in maintaining a clean work environment while remaining vigilant about potential hazards linked with various types of industrial processes.

Conclusion

In the world of laser cutting, ensuring safety is paramount. The potential hazards posed by laser dust, particularly aluminum dust hazards, can have serious implications for operators if not managed properly. By understanding the types of dust generated during these processes and implementing effective dust collection systems, businesses can create a safer working environment.

Ensuring Safety in Laser Cutting Operations

Operators often wonder, Is laser dust harmful? The answer is a resounding yes if proper precautions are not taken. Exposure to various types of dust can lead to respiratory issues and other health concerns over time, making it critical to prioritize safety measures in laser cutting operations.

It’s essential to recognize that aluminum dust hazards are particularly concerning due to their flammable nature and potential for creating explosive atmospheres. Therefore, implementing robust safety protocols and using efficient centralized dust collection systems can significantly mitigate these risks. Regular training for operators on recognizing the dangers of laser dust will also enhance workplace safety.

Investing in Quality Dust Collection Systems

Investing in high-quality dust collection systems is not just a choice; it's a necessity for any serious operation involved in laser cutting or aluminum dust extraction. With various types of dust collection systems available—ranging from localized setups to centralized solutions—businesses must carefully evaluate their needs before making a decision.

A well-designed centralized dust collection system can effectively handle large volumes of particulate matter while ensuring that the workspace remains clean and safe for operators. Moreover, regular maintenance practices such as heavy equipment air filter cleaning are crucial to prolonging the life and efficiency of these systems. Ultimately, quality investments lead to long-term benefits in both productivity and worker health.

The Future of Dust Extraction Technology

The future of dust extraction technology looks promising with advancements aimed at enhancing efficiency and safety in industries like aerospace manufacturing where specific regulations for aerospace dust extraction apply. Innovations are focusing on smart technologies that monitor air quality in real-time, providing immediate feedback on harmful particle levels including those from aluminum cutting processes.

As industries grow more aware of the importance of managing aluminum dust hazards effectively, we can expect an increase in research dedicated to developing better filtration methods and more compact designs for centralized systems. This evolution will ensure that businesses remain compliant with regulations while safeguarding their most valuable asset—their workforce.