Introduction

In the bustling world of industrial environments, the management of dust is not just a matter of cleanliness; it’s a critical aspect that directly impacts safety and efficiency. Enter the wet dust collection system, an innovative solution designed to tackle the challenges posed by airborne particles. By utilizing water in conjunction with advanced filtration techniques, these systems provide a comprehensive approach to dust control, ensuring that workplaces remain safe and operational.

Understanding Wet Dust Collection Systems

Wet dust collection systems serve as an essential tool in the fight against hazardous dust accumulation. Unlike traditional dry collectors that may simply recirculate particles back into the air, a wet dust collection system captures and neutralizes harmful dust using moisture, effectively preventing it from becoming airborne again. This method not only enhances the overall effectiveness of an industrial dust collector but also ensures that contaminants are managed more sustainably.

Importance of Safety in Industrial Environments

Safety in industrial settings cannot be overstated; it is paramount for both workers and operational integrity. The presence of fine particulate matter poses significant risks, including respiratory issues and potential fire hazards if left unchecked. Implementing a robust dust collection system is essential for maintaining compliance with safety regulations while fostering a healthier work environment for everyone involved.

How Dust Controls Enhance Efficiency

Dust controls are more than just safety measures; they are integral to enhancing operational efficiency within manufacturing processes. An effective industrial dust removal system minimizes downtime caused by equipment malfunctions due to accumulated debris while also improving air quality for workers on the floor. By investing in advanced solutions like wet dust filtration systems, companies can optimize productivity while safeguarding employee well-being.

The Mechanics of a Wet Dust Collection System

Understanding the inner workings of a wet dust collection system is essential for grasping its efficiency and safety benefits in industrial environments. These systems utilize water to capture and filter harmful dust particles, ensuring cleaner air quality and reducing health risks for workers. By examining how these systems function in real-time, we can appreciate their role in modern industrial dust management.

How It Works in Real-time

A wet dust collection system operates by drawing contaminated air through a series of filters or scrubbers where water is introduced to the airflow. As the air passes through, dust particles collide with water droplets, causing them to adhere and form larger aggregates that are easier to capture. This process not only removes harmful particulates but also cools the air, creating a more comfortable environment for workers.

In real-time operations, these systems continuously cycle water and air, ensuring efficient filtration while minimizing downtime for maintenance. The collected dust settles into a reservoir where it can be safely disposed of or processed further. This dynamic interaction between airflow and water is what sets wet collectors apart from traditional dry methods.

Comparing with Traditional Dust Collection Methods

When comparing wet dust collection systems to traditional dry collectors, several key differences emerge that highlight their advantages. Traditional industrial dust collectors often rely on fabric filters or baghouses that can become clogged with fine particulate matter, leading to reduced efficiency over time. In contrast, wet systems maintain consistent performance by utilizing water as a medium for capturing even the smallest particles.

Moreover, traditional methods may generate airborne dust during filter changes or maintenance activities; this is significantly reduced with an industrial dust removal system that employs moisture as part of its operation. While both systems aim to achieve effective dust filtration, wet methods offer superior safety benefits by minimizing fire hazards associated with combustible dusts often found in dry collection processes.

The Role of Water in Dust Filtration

Water plays a crucial role in enhancing the efficacy of any wet dust collection system by acting as both a binding agent and a cooling medium during filtration processes. When combined with mechanical forces within the collector, water droplets effectively trap airborne particles before they can escape back into the workspace atmosphere. This unique approach not only improves overall filtration efficiency but also ensures compliance with stringent environmental regulations regarding airborne pollutants.

Additionally, the use of water helps mitigate common issues faced by dry collectors such as static electricity buildup and filter degradation due to excessive heat generated during operation. As such, incorporating an industrial dust collection system that leverages water not only promotes cleaner workspaces but also contributes significantly to worker safety and health standards within various industries.

Safety Benefits of Wet Dust Collection

In the realm of industrial operations, safety is paramount, and a wet dust collection system offers numerous advantages that enhance worker protection. By effectively managing dust particles, these systems not only improve air quality but also contribute to a safer working environment. Let’s explore how a wet dust collection system can significantly reduce hazards associated with dust accumulation.

Reducing Fire and Explosion Risks

One of the most compelling reasons to implement an industrial dust collection system is its role in mitigating fire and explosion risks. Dust particles can ignite when exposed to heat or sparks, leading to catastrophic incidents in industrial settings. A wet dust collection system minimizes this risk by using water to suppress combustible dust, ensuring that any potentially hazardous materials are contained and safely removed from the workspace.

Moreover, traditional dry collectors may not be as effective at controlling fine particles that can become airborne during operations. In contrast, the water used in a wet dust collector provides an additional layer of safety by dampening these particles before they have a chance to ignite. By investing in an industrial dust removal system equipped with wet filtration technology, companies can create a safer environment for their employees while also protecting valuable equipment and infrastructure.

Minimizing Respiratory Hazards for Workers

Another significant advantage of employing a wet dust collection system is its ability to minimize respiratory hazards for workers exposed to harmful airborne particles. Many industries generate fine particulate matter that can lead to chronic health issues if inhaled over time—think along the lines of silica or wood dust! The efficient filtration capabilities of an industrial dust collector help capture these particulates before they enter the workplace atmosphere.

In addition, using water in the filtration process helps maintain humidity levels within acceptable ranges, further reducing airborne contaminants that could affect worker health. This proactive approach not only safeguards employees’ well-being but also promotes higher productivity levels as workers feel more comfortable in cleaner air environments. Ultimately, adopting an industrial dust collection system enhances overall workplace morale while minimizing health-related absenteeism.

Keeping Workspaces Safer and Cleaner

A clean workspace is synonymous with safety; it reduces accidents caused by slips or falls due to accumulated debris or clutter from uncollected dust particles. Implementing an effective wet dust collection system ensures that workplaces remain tidy by continuously removing unwanted materials during operations—no more sweeping dirt into corners! This ongoing maintenance prevents buildup and keeps work areas organized.

Moreover, regular use of an industrial dust removal system contributes positively toward compliance with industry regulations regarding cleanliness and safety standards set forth by organizations like OSHA and EPA. When facilities prioritize cleanliness through effective filtration methods such as those found in wet collectors, they foster environments where employees can focus on their tasks without distraction or concern about potential hazards lurking beneath layers of accumulated debris.

In summary, investing in advanced technologies like a wet dust collection system not only improves operational efficiency but also enhances overall safety within industrial environments—making it a win-win situation for all involved!

NAROO’s Innovative Solutions

In the realm of industrial dust management, NAROO stands out with its cutting-edge technologies designed to revolutionize wet dust collection systems. By focusing on efficiency and safety, NAROO has developed a suite of solutions that enhance the performance of dust collection systems across various industries. These innovations not only improve dust filtration but also ensure compliance with stringent safety regulations.

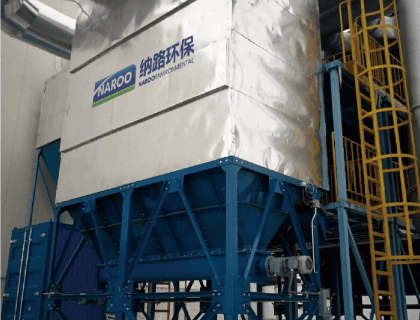

Overview of NAROO’s Technologies

NAROO's technologies are engineered to optimize the effectiveness of industrial dust collectors while minimizing environmental impact. Their wet dust collection system employs advanced filtration techniques that capture fine particles and prevent them from becoming airborne, thus enhancing workplace safety. This innovative approach ensures that every collector dust particle is effectively managed, resulting in cleaner air and a healthier work environment.

The integration of smart technology into their industrial dust removal system allows for real-time monitoring and adjustments, ensuring optimal performance at all times. This means that facility managers can focus on production without worrying about the efficiency of their dust collection system. With these innovative solutions, NAROO is not just keeping up with industry standards; they are setting them.

Case Studies of NAROO Implementations

Numerous case studies highlight the successful implementation of NAROO's technologies in various settings, showcasing significant improvements in air quality and operational efficiency. For instance, a leading manufacturing plant adopted NAROO's wet dust collection system and reported a 50% reduction in airborne particulate matter within just weeks of installation. This transformation resulted in fewer health-related absences among employees and an overall increase in productivity.

Another notable example involves a woodworking facility that struggled with excessive wood dust accumulation impacting both safety and equipment performance. After integrating NAROO’s industrial dust collector solutions, they experienced enhanced dust filtration capabilities and reduced fire hazards associated with dry wood chips igniting spontaneously. Such case studies illustrate how effective an industrial dust removal system can be when leveraging advanced technologies like those offered by NAROO.

How NAROO Enhances Dust Removal Systems

NAROO enhances traditional industrial dust collection systems by incorporating features that address common challenges faced by facilities today. Their approach includes using high-efficiency filters designed specifically for wet applications, which significantly increases the lifespan of both filters and equipment while reducing maintenance costs over time. With better durability comes less downtime—a crucial factor for any production-oriented business looking to maximize output.

Moreover, their systems are designed to be modular, allowing companies to customize their setup according to specific needs without extensive overhauls or additional investments in new equipment later on. This adaptability makes it easier for businesses to scale operations while maintaining robust dust filtration processes as they grow or change focus over time. Ultimately, through continuous innovation and commitment to excellence, NAROO ensures that every element of its wet dust collection system contributes positively to workplace safety and operational efficiency.

Compliance and Regulatory Standards

In the world of industrial operations, compliance with regulatory standards is not just a box to check; it's a vital aspect of maintaining a safe and efficient workplace. A wet dust collection system plays a crucial role in meeting the stringent guidelines set by organizations like OSHA (Occupational Safety and Health Administration) and the EPA (Environmental Protection Agency). These regulations are designed to protect workers from hazardous dust exposure while ensuring that industrial dust collectors operate effectively within legal limits.

Meeting OSHA and EPA Guidelines

To comply with OSHA and EPA guidelines, businesses must implement effective dust management strategies, including the installation of an industrial dust collection system. These systems are engineered to capture harmful particles before they can escape into the air, thus safeguarding employees' health. By utilizing a wet dust collection system, companies can significantly reduce airborne contaminants while adhering to safety standards that govern permissible exposure levels.

Moreover, these regulations often dictate specific performance metrics for collector dust systems, such as filtration efficiency and emissions limits. A well-designed wet dust filtration unit not only meets but can exceed these requirements, providing an additional layer of assurance for employers concerned about compliance risks. Ultimately, staying ahead of these guidelines enhances overall workplace safety and minimizes potential liabilities.

Importance of a Dust Collection System for Compliance

The importance of having an effective dust collection system cannot be overstated when it comes to regulatory compliance. An industrial dust removal system is essential in industries where fine particulate matter poses significant health risks to workers. Without such a system in place, companies may face hefty fines or even shutdowns due to non-compliance with established safety regulations.

Furthermore, implementing a robust industrial dust collector not only helps meet legal obligations but also fosters a culture of safety within the organization. Employees are more likely to feel secure in their work environment when they see that their employer prioritizes protection against harmful exposure through effective systems like wet dust collection units. This proactive approach can enhance morale while reducing turnover rates associated with unsafe working conditions.

Benefits of Staying Ahead of Regulations

Staying ahead of compliance regulations offers numerous benefits beyond mere avoidance of penalties; it positions companies as industry leaders committed to best practices in worker safety and environmental stewardship. By investing in advanced technologies like wet dust collection systems, organizations can improve operational efficiency while demonstrating corporate responsibility toward employee welfare and environmental impact reduction.

Additionally, being proactive about compliance allows businesses to anticipate changes in regulations before they become mandatory requirements—an advantage that can save time and resources in the long run. Companies equipped with modern industrial dust collectors are often better prepared for audits or inspections since they have already integrated necessary adjustments into their operations ahead of time.

Lastly, exceeding regulatory expectations enhances brand reputation among clients and stakeholders alike; it signals reliability and dedication to quality standards that resonate well within competitive markets. In essence, investing in compliant solutions today prepares businesses for sustainable growth tomorrow.

Best Practices for Implementing a Wet Dust Collection System

Implementing a wet dust collection system effectively requires careful planning and consideration of various factors. By following best practices, facilities can optimize their industrial dust collection systems for safety and efficiency. This ensures that the collector dust is managed properly while minimizing risks associated with airborne particles.

Assessing Your Facility’s Needs

Before diving into the installation of a wet dust collection system, it's crucial to assess your facility's unique requirements. Each industrial environment produces different types of dust, which affects the choice of an appropriate industrial dust collector. A thorough evaluation will help determine the volume and nature of the dust being generated, ensuring that the selected dust collection system is tailored to meet those specific needs.

Another essential factor during this assessment phase is understanding local regulations regarding air quality and emissions. Knowing these guidelines helps in selecting an industrial dust removal system that not only meets operational demands but also adheres to compliance standards set by authorities like OSHA and EPA. Ultimately, a well-planned approach leads to more effective filtration and cleaner workspaces.

Regular Maintenance for Optimal Performance

Once your wet dust collection system is up and running, regular maintenance becomes paramount for optimal performance. Just like any other machinery in your facility, an industrial dust collection system requires routine checks to ensure it operates efficiently over time. Neglecting maintenance can lead to decreased performance in capturing collector dust, increasing the risk of hazardous conditions.

Scheduled inspections should include checking water levels, cleaning filters, and ensuring that all components are functioning correctly within the system. By adhering to a maintenance schedule, you can prolong the lifespan of your equipment while enhancing its effectiveness in controlling airborne pollutants through efficient dust filtration methods. Remember: a well-maintained system not only improves safety but also boosts productivity across your operations.

Training Employees on Safety Protocols

An often-overlooked aspect when implementing a wet dust collection system is training employees on proper safety protocols associated with its use. It’s vital that workers understand how to operate both the industrial dust collector effectively and safely handle any potential hazards related to collected materials or water exposure during operation. Comprehensive training sessions should cover everything from basic operation principles to emergency procedures if something goes awry.

Regular refresher courses can help keep safety top-of-mind among employees while fostering a culture of accountability regarding workplace cleanliness and safety standards associated with an industrial dust removal system. Empowered employees who are knowledgeable about their equipment contribute significantly toward maintaining an efficient environment where health risks are minimized through effective use of wet systems for controlling collector dust levels throughout operations.

Conclusion

In the ever-evolving landscape of industrial operations, maximizing worker safety with effective dust control measures is not just a regulatory requirement; it's a moral imperative. A wet dust collection system stands out as a reliable solution that not only captures harmful particles but also minimizes fire risks and respiratory hazards. By investing in robust dust filtration systems, industries can create safer work environments that enhance productivity and employee well-being.

Maximizing Worker Safety with Dust Control

Implementing an industrial dust collector is essential for safeguarding employees from the perils of airborne contaminants. A well-designed dust collection system ensures that harmful particles are effectively captured and neutralized, thus promoting a healthier workplace atmosphere. With advancements in technology, modern wet dust collection systems are becoming increasingly efficient at removing hazardous substances while keeping the workspace cleaner.

The Future of Industrial Dust Collection Systems

The future of industrial dust removal systems is undoubtedly bright, with innovations continuously shaping how we approach air quality management in manufacturing environments. As industries evolve, so too do the technologies that underpin these systems, paving the way for smarter and more efficient solutions like advanced wet dust collection systems. The integration of automation and real-time monitoring will further enhance the effectiveness of these collectors, ensuring compliance and optimal performance.

Investing in Reliable Solutions for Sustainability

Sustainability should be at the forefront when considering an industrial dust collection system for your facility. By investing in reliable wet dust collection systems, companies not only comply with OSHA and EPA regulations but also contribute to environmental preservation by minimizing waste emissions. Moreover, embracing cutting-edge technologies ensures that organizations remain competitive while fostering a culture of safety and responsibility among their workforce.