Introduction

In the bustling world of industrial operations, maintaining cleanliness and safety is paramount. Enter the industrial vacuum cleaning machine—a vital tool designed to tackle everything from everyday debris to hazardous combustible dust. As industries evolve, so do the technologies and features of these machines, making it essential for businesses to stay informed about their options.

Understanding Industrial Vacuum Cleaning Machines

Industrial vacuum cleaning machines are not your average household cleaners; they are robust, specialized units built to handle heavy-duty tasks in various environments. These machines vary widely in design and function, catering to specific needs such as combustible dust cleaning or managing aluminum dust in manufacturing settings. Understanding their capabilities allows businesses to select a model that aligns perfectly with their operational requirements.

The Importance of Choosing Wisely

Choosing the right industrial vacuum cleaning machine can significantly impact workplace efficiency and safety. A well-suited machine not only enhances productivity but also ensures compliance with health regulations concerning airborne contaminants like combustible metals and dust. Making an informed choice means considering factors like filtration systems—particularly those equipped with industrial HEPA filters—which are crucial for maintaining air quality in industrial spaces.

Key Features to Consider

When selecting an industrial vacuum cleaning machine, several key features should be top of mind. First, consider the type of debris you'll be dealing with; machines designed for combustible dust cleaning often come equipped with specialized filters and safety mechanisms tailored for such materials. Additionally, look for models that offer versatility—capable of handling both aluminum dust and general debris—while ensuring ease of maintenance and operation.

The Diverse World of Industrial Vacuum Cleaning Machines

In the realm of industrial cleaning, vacuum machines come in various shapes and sizes, tailored to meet the specific needs of different industries. The right industrial vacuum cleaning machine can make all the difference in efficiency and safety, especially when dealing with hazardous materials like combustible dust. Understanding the types available is crucial for selecting a machine that suits your operational requirements.

Types of Machines for Various Industries

Industrial vacuum cleaning machines are designed to handle a range of tasks across diverse sectors, from manufacturing to food processing. For instance, some models are specifically engineered for heavy-duty applications, featuring robust motors and enhanced suction capabilities ideal for construction sites or factories. Others may focus on lighter tasks but come equipped with specialized attachments to tackle unique challenges faced in environments like laboratories or clean rooms.

Moreover, there are variations that cater specifically to wet and dry applications, ensuring versatility in handling different types of debris. These machines often have interchangeable filters and collection systems, allowing users to switch between tasks without hassle. Ultimately, understanding these distinctions helps businesses choose an industrial vacuum cleaning service that aligns perfectly with their operational needs.

Applications in Combustible Dust Cleaning

Industries such as woodworking and metalworking generate fine particles that can pose serious fire hazards if not managed properly. Specialized vacuums designed for combustible dust ensure efficient collection while minimizing risks associated with ignition.

These machines typically feature advanced filtration systems like industrial HEPA filters that capture even the smallest particles effectively. Additionally, they are built with anti-static features to prevent sparks during operation—a critical consideration when dealing with combustible metals or other flammable materials. By investing in an appropriate machine for combustible dust cleaning, companies not only protect their workers but also enhance productivity by maintaining cleaner work environments.

Specialized Models for Aluminum Dust

Aluminum dust presents unique challenges due to its lightweight nature and potential explosiveness when airborne; thus requiring specialized models within the realm of industrial vacuum cleaning machines. These vacuums are specifically designed to handle aluminum dust safely while complying with industry regulations regarding combustible materials. They often employ high-efficiency particulate air (HEPA) filters tailored for metal particulates.

Furthermore, many models include features such as spark-resistant construction and explosion-proof designs which greatly reduce risks associated with aluminum dust accumulation during manufacturing processes or machining operations. Utilizing an industrial vacuum cleaning service equipped with these specialized models ensures effective removal of aluminum debris while safeguarding against potential hazards inherent in handling combustible metals.

Assessing Your Cleaning Needs

Every work environment presents unique challenges, from the type of debris generated to the safety regulations that must be adhered to. A tailored approach ensures that you invest in an industrial vacuum cleaning service that meets your operational demands effectively.

Evaluating Work Environments

The first step in assessing your cleaning needs is evaluating your work environment. Different industries—such as manufacturing, construction, and food processing—generate various types of debris, including combustible dust and aluminum dust. By identifying the specific conditions of your workspace, you can select an industrial vacuum cleaning machine designed for those particular challenges.

For instance, environments where combustible metals are present require specialized machines equipped with features to manage these hazards safely. Factors like floor space, accessibility, and potential hazards should all influence your choice of equipment. Ultimately, a thorough evaluation will lead you to a more efficient and effective cleaning solution.

Determining the Volume of Debris

Next on the checklist is determining the volume of debris you'll be dealing with on a regular basis. This isn't just about how much dust accumulates; it's also about understanding what kind of materials are being cleaned up by your industrial vacuum cleaning services. High volumes of combustible dust necessitate robust machinery capable of handling significant loads without compromising performance or safety.

Understanding Industrial HEPA Filter Requirements

Finally, don’t overlook the importance of understanding industrial HEPA filter requirements when choosing an industrial vacuum cleaning machine. These filters play a critical role in ensuring that harmful particles are captured and not released back into the air during cleanup operations—a vital consideration when working with combustible metals or fine aluminum dust.

Selecting an appropriate HEPA filter means considering both its efficiency in trapping particulates and its compatibility with your chosen machine’s design and specifications. Regular maintenance and timely replacement are essential for keeping these filters functioning optimally; otherwise, they could become a liability rather than an asset in maintaining workplace safety standards.

In summary, assessing your specific cleaning needs involves evaluating work environments carefully, determining debris volumes accurately, and understanding HEPA filter requirements thoroughly—all crucial steps toward making an informed purchase decision for your industrial vacuum cleaning services.

The Role of Safety Standards

Compliance with regulations ensures that the machines operate within safe parameters, reducing the risk of accidents in environments where combustible dust is prevalent. Ignoring these standards can lead to severe consequences, including costly fines and hazardous working conditions.

Importance of Compliance with Regulations

Adhering to safety regulations is crucial for any business using industrial vacuum cleaning services, especially those dealing with combustible dust or metals. These regulations are designed to minimize risks associated with fire and explosion hazards, which can be prevalent in industries handling materials like aluminum dust. By ensuring compliance, companies not only protect their employees but also enhance their reputation as responsible operators in their respective fields.

Ensuring Safe Handling of Combustible Metals

Handling combustible metals requires specialized attention when using an industrial vacuum cleaning machine. These machines must be equipped to effectively manage aluminum dust and other similar materials without risking ignition or explosion. Proper training in the use of these machines further ensures that employees understand the importance of maintaining a safe environment while conducting combustible dust cleaning operations.

Choosing Machines with Built-In Safety Features

Investing in an industrial vacuum cleaning machine that includes built-in safety features is a wise choice for any organization focused on worker safety and compliance. Look for models equipped with advanced filtration systems, such as industrial HEPA filters, that capture fine particles and prevent them from escaping back into the air. Additionally, features like automatic shut-off mechanisms can provide extra layers of protection against potential hazards when dealing with combustible materials.

Exploring Brand Reputation

A trusted brand not only provides superior products but also guarantees ongoing support and service, which is essential for maintaining efficiency in industrial vacuum cleaning services. As industries increasingly demand specialized solutions for combustible dust cleaning and other applications, the choice of manufacturer can significantly impact operational success.

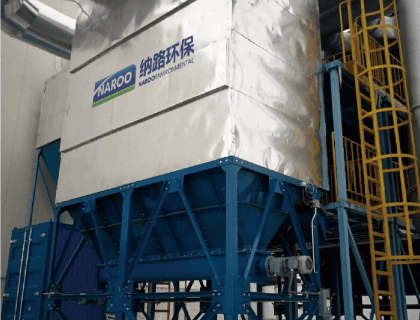

Why NAROO Leads the Industry

NAROO has established itself as a frontrunner in the realm of industrial vacuum cleaning machines due to its unwavering commitment to innovation and quality. Their machines are engineered with advanced technology, ensuring optimal performance when dealing with challenging materials like aluminum dust and combustible metals. Moreover, NAROO’s focus on incorporating high-performance industrial HEPA filters sets them apart by enhancing air quality while effectively capturing harmful particles.

Recognizing Other Trusted Manufacturers

While NAROO stands out, several other manufacturers have earned their stripes in the field of industrial vacuum cleaning services. Brands such as Nilfisk, Kärcher, and Dustcontrol have developed robust reputations for producing reliable machines that cater to various industry needs. These companies also prioritize safety features and compliance with regulations critical for environments that handle combustible dust or metals, providing peace of mind alongside effective cleaning solutions.

Benefits of Established Brands in Industrial Vacuum Cleaning Services

Choosing an established brand for your industrial vacuum cleaning machine comes with a host of advantages that extend beyond just product reliability. These brands often invest significantly in research and development, resulting in cutting-edge technologies that enhance efficiency during tasks like combustible dust cleaning or managing aluminum dust. Additionally, reputable manufacturers usually offer comprehensive customer support services that ensure your equipment is well-maintained and any issues are swiftly resolved—keeping your operations running smoothly.

Maintenance and Support Considerations

Regular upkeep ensures that these machines operate at peak efficiency, especially when dealing with challenging tasks like combustible dust cleaning or aluminum dust removal. Neglecting maintenance can lead to performance issues, increased downtime, and even safety hazards in environments dealing with combustible metals.

Importance of Regular Maintenance

Regular maintenance of your industrial vacuum cleaning machine is crucial for extending its lifespan and ensuring optimal performance. This includes routine checks on the industrial HEPA filter, which plays a vital role in trapping fine particles and preventing them from re-entering the air. By keeping up with maintenance schedules, you not only enhance the machine's efficiency but also reduce the risk of accidents related to combustible dust accumulation.

Moreover, a well-maintained industrial vacuum cleaning machine can save your business money in the long run by minimizing repair costs and avoiding premature replacements. Ensuring that all components are functioning correctly allows for smooth operations in demanding environments where combustible metals are present. In summary, regular maintenance is integral to maintaining safety standards while maximizing productivity.

Evaluating Customer Support Services

Choosing an industrial vacuum cleaning machine means considering not only the product itself but also the level of customer support available post-purchase. Reliable customer support services can make all the difference when you encounter issues or need guidance on using your machine effectively for tasks such as combustible dust cleaning or aluminum dust management. Look for manufacturers that offer comprehensive warranties, responsive helplines, and accessible online resources.

Additionally, consider whether they provide training sessions or tutorials on maintaining your industrial vacuum cleaning machine properly. A company that invests in customer education demonstrates its commitment to ensuring customers get the most out of their investment—whether through regular servicing tips or troubleshooting advice. Ultimately, strong customer support can help you navigate any challenges that arise during operation.

Knowing When to Upgrade Your Machine

Understanding when it's time to upgrade your industrial vacuum cleaning machine is essential for keeping pace with evolving industry demands and safety standards. If you find yourself frequently repairing older models or if they struggle to handle increasing volumes of debris—especially hazardous materials like combustible metals—it may be time for an upgrade. Newer models often come equipped with advanced features designed specifically for efficient combustible dust cleaning and improved filtration systems.

Furthermore, advancements in technology mean that modern machines are more energy-efficient and effective at capturing fine particles compared to their predecessors equipped only with standard filters instead of specialized industrial HEPA filters. Upgrading not only enhances operational efficiency but also strengthens workplace safety by reducing potential risks associated with outdated equipment handling hazardous materials like aluminum dust.

In conclusion, prioritizing maintenance while evaluating customer support services will ensure your investment in an industrial vacuum cleaning machine pays off long-term; knowing when to upgrade keeps you ahead of potential pitfalls associated with aging machinery.

Conclusion

In the rapidly evolving world of industrial vacuum cleaning machines, making informed decisions is crucial for maximizing efficiency and safety. With a myriad of options available, understanding key features and applications can significantly impact your cleaning operations. By considering factors such as compliance with safety standards and the specific needs of your environment, you can select the right equipment that meets both performance and regulatory requirements.

Key Takeaways for Smart Purchasing

When investing in an industrial vacuum cleaning machine, prioritize understanding your specific cleaning needs—this includes evaluating work environments and the types of debris you'll encounter. For instance, if you're dealing with combustible dust cleaning or aluminum dust, ensure that the machine is equipped with an industrial HEPA filter to capture fine particles effectively. Additionally, consider the reputation of manufacturers like NAROO; established brands often provide reliable support and maintenance services that are invaluable in keeping your operations running smoothly.

Future Trends in Industrial Vacuum Technology

The future of industrial vacuum technology promises exciting advancements aimed at enhancing efficiency and safety in various industries. Innovations such as smart sensors for real-time monitoring will allow operators to optimize performance while ensuring compliance with safety standards related to combustible metals. Furthermore, developments in eco-friendly designs will lead to more sustainable options for industrial vacuum cleaning services, catering to an increasingly environmentally conscious market.

Partnering with Experts like NAROO

Choosing a trusted partner like NAROO can make all the difference when navigating the complex landscape of industrial vacuum cleaning machines. Their expertise not only ensures access to high-quality equipment but also provides valuable insights into best practices for managing combustible dust cleaning and other specialized applications. By collaborating with industry leaders, you position your business at the forefront of innovation while ensuring that you meet all necessary safety regulations effectively.