Introduction

In the world of manufacturing and construction, dust extraction systems play a pivotal role in maintaining a safe and efficient workspace. Grinding dust extraction is not just about cleanliness; it’s essential for protecting workers' health and ensuring compliance with safety regulations. As industries evolve, so do the technologies behind dust extraction, leading to more effective solutions that benefit both workers and productivity.

The Importance of Dust Extraction Systems

Dust extraction systems are crucial in mitigating the hazards associated with airborne particles generated during grinding operations. Without proper grinding dust extraction, harmful particles can accumulate, posing serious risks such as respiratory issues and decreased visibility in work areas. Implementing effective dust extraction not only safeguards employee health but also enhances overall operational efficiency by reducing downtime caused by cleanup efforts.

Benefits of Effective Grinding Dust Extraction

The benefits of effective grinding dust extraction extend beyond mere cleanliness; they encompass improved air quality, increased worker morale, and enhanced equipment longevity. By utilizing a reliable dust extraction grinder, companies can significantly reduce the volume of harmful particulates in the air, creating a healthier environment for employees. Furthermore, cleaner workspaces lead to less wear on machinery and tools, ultimately saving costs related to maintenance and replacement.

Key Features of Modern Dust Filtration Systems

Modern dust filtration systems boast several key features designed to maximize efficiency while minimizing environmental impact. Advanced technologies like HEPA filters ensure that even the tiniest particles are captured during grinding operations, which is essential for maintaining air quality standards. Additionally, many contemporary systems offer portability options and user-friendly interfaces that make them suitable for various applications—from stationary setups to mobile units used alongside cutting grinders.

Understanding Grinding Dust Extraction

Grinding dust, often generated from materials like metal, wood, or plastic, can pose serious health risks if not properly managed. Effective dust extraction systems are designed to capture these harmful particles before they can infiltrate the air we breathe.

What is Grinding Dust?

Grinding dust refers to the fine particles produced during the grinding process when materials are abraded or cut away. These particles can vary in size and composition depending on the material being worked on—metal shavings from a cutting grinder, wood chips from sanding, or even concrete dust from masonry work. Given their microscopic nature, these particles can easily become airborne and contribute to respiratory issues if inhaled over time.

The Role of Dust Extraction in Safety

The role of dust extraction in safety cannot be overstated; it serves as a frontline defense against occupational hazards associated with airborne particulates. Without an effective dust extraction system in place, workers may face health risks such as lung disease or other respiratory conditions due to prolonged exposure to grinding dust. By implementing a robust dust extraction grinder system, businesses not only comply with safety regulations but also promote a healthier work environment for their employees.

Types of Grinding Dust Extraction Systems

There are various types of grinding dust extraction systems available on the market today, each tailored for specific applications and environments. Portable systems offer flexibility for small workshops or job sites where mobility is key; they allow users to easily transport their cutting grinder setups without sacrificing performance. On the other hand, stationary systems provide powerful suction capabilities ideal for larger production facilities where high-volume grinding occurs regularly—ensuring that no harmful particles escape into the air.

Choosing the Right Dust Extraction Grinder

Selecting the right dust extraction grinder is pivotal to maintaining a clean and safe workspace. With various options available, understanding the specific features that enhance grinding dust extraction can make all the difference. This section will guide you through essential features, compare portable and stationary systems, and recommend trusted brands for quality equipment.

Features to Look for in a Cutting Grinder

First off, look for grinders equipped with powerful suction capabilities; this ensures that most of the grinding dust is captured before it can settle into your workspace. Additionally, consider grinders with built-in filtration systems—these dust filtration systems help trap fine particles that standard filters might miss, keeping your air cleaner.

Another important feature is ease of maintenance; a grinder with accessible components makes regular cleaning a breeze, prolonging its lifespan and efficiency. Furthermore, noise levels should also be taken into account; quieter models contribute to a more pleasant working environment without sacrificing power or efficiency. Lastly, ergonomic designs can enhance user comfort during extended use—a crucial factor when you're grinding away all day.

Comparing Portable vs. Stationary Systems

When choosing between portable and stationary dust extraction systems, each has its unique advantages tailored to different needs in grinding operations. Portable models are ideal for those who require mobility; they allow users to move from one job site to another while ensuring effective grinding dust extraction wherever they go. These systems often come with compact designs but may sacrifice some suction power compared to their stationary counterparts.

On the other hand, stationary systems typically offer superior suction capabilities and larger capacity for collecting grinding dust over extended periods. They are perfect for workshops where space is dedicated solely to cutting tasks; their robust design allows them to handle heavy-duty applications without breaking a sweat. Ultimately, your choice should depend on your specific needs—whether you prioritize mobility or maximum performance in one location.

Recommended Brands for Quality Equipment

With so many options available in the market today, finding reliable brands that specialize in cutting grinders can save you time and frustration down the line. Some top contenders include Festool and Makita—both known for their innovative designs and exceptional performance in dust extraction grinders that effectively capture fine particles during operation. Another brand worth mentioning is DeWalt; they have consistently delivered high-quality tools equipped with advanced dust filtration systems.

For those on a budget yet still seeking reliable equipment, consider brands like Bosch or Ryobi—they offer solid performance at more accessible price points without compromising on essential features like efficient grinding dust extraction capabilities. Additionally, check out reviews from other users before making a purchase; real-world feedback often highlights strengths and weaknesses you might not have considered initially.

Exploring Advanced Dust Filtration Systems

In the realm of grinding dust extraction, advanced dust filtration systems play a pivotal role in ensuring clean air and a safe working environment. These systems are designed to capture and filter out harmful particles generated during grinding processes, significantly improving air quality. With the right dust extraction systems, you can not only enhance productivity but also safeguard the health of everyone in your workshop.

How Dust Filtration Works

Dust filtration works through a systematic approach that combines several technologies to effectively remove particles from the air. Initially, air laden with grinding dust is drawn into the system using powerful fans, where it passes through various filters designed to trap different sizes of particles. The filtered air is then recirculated back into the workspace or expelled outside, ensuring that harmful contaminants are kept at bay while maintaining optimal airflow for your cutting grinder operations.

Importance of Air Quality in Workshops

Maintaining high air quality in workshops is crucial for both health and productivity. Poor air quality due to excessive grinding dust can lead to respiratory issues, decreased worker efficiency, and potential long-term health risks. By investing in reliable dust extraction grinders equipped with advanced filtration systems, businesses can create a safer environment that promotes better concentration and overall well-being among employees.

Top Filtration Technologies on the Market

The market offers a variety of cutting-edge filtration technologies tailored for effective grinding dust extraction. HEPA filters are renowned for their ability to capture 99.97% of particles as small as 0.3 microns, making them ideal for workshops dealing with fine dust. Additionally, electrostatic precipitators and cyclonic separators are gaining popularity due to their efficiency in removing larger particles while reducing maintenance needs—perfect companions for any robust dust extraction system.

Maintenance Tips for Dust Extraction Systems

Maintaining your dust extraction systems is crucial for ensuring they operate efficiently and effectively. Regular upkeep not only prolongs the life of your equipment but also enhances safety in the workplace by minimizing exposure to harmful grinding dust. By following a few simple maintenance tips, you can keep your dust extraction grinder performing at its best.

Regular Cleaning and Upkeep

Regular cleaning is essential for any dust extraction system, especially those used for grinding operations. Dust can accumulate quickly in filters and ducts, reducing airflow and efficiency, which compromises the effectiveness of your grinding dust extraction efforts. Schedule routine inspections to clean or replace filters, empty collection bags, and check for any blockages that might hinder performance.

Additionally, don't forget about the exterior components of your dust filtration systems; keeping them clean helps prevent any accidental hazards caused by debris buildup. Use appropriate cleaning supplies that won't damage sensitive parts while ensuring all surfaces are free from accumulated grime. A little proactive care goes a long way in maintaining optimal function and safety.

Troubleshooting Common Issues

Even the best dust extraction grinders can encounter issues from time to time, so knowing how to troubleshoot common problems is vital. If you notice decreased suction or increased noise levels during operation, it may indicate a clogged filter or an issue with the motor itself. Start by checking for blockages in hoses or ducts; often, a simple cleaning can restore functionality.

Another common issue is excessive wear on components due to prolonged use without proper maintenance; be vigilant about replacing worn parts before they cause more significant problems down the line. Keep an eye on warning signs such as unusual vibrations or overheating—these could indicate serious malfunctions that require immediate attention to avoid costly repairs later on.

When to Seek Professional Help

While many maintenance tasks can be handled independently, there are times when seeking professional help becomes necessary—especially with complex dust extraction systems like those used in industrial settings. If you find yourself facing persistent issues that basic troubleshooting hasn’t resolved, it’s wise to call in an expert who specializes in grinding dust extraction systems.

Professional technicians have the experience and tools needed to diagnose deeper problems that may not be immediately apparent during regular maintenance checks. Additionally, if you're considering upgrades or modifications to enhance your existing setup—like integrating advanced dust filtration technologies—consulting with professionals ensures you make informed decisions tailored to your specific needs.

Case Studies: Success Stories in Dust Extraction

In the world of manufacturing and workshops, effective dust extraction systems can make or break the efficiency and safety of operations. This section dives into real-life examples that showcase how companies have transformed their processes through advanced grinding dust extraction solutions. From increased productivity to enhanced worker safety, these case studies illustrate the undeniable benefits of investing in quality dust filtration systems.

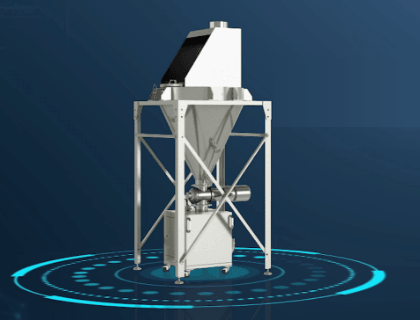

Kiant Machinery's Impact on Efficiency

Kiant Machinery is a prime example of how modern dust extraction systems can revolutionize manufacturing processes. By integrating a state-of-the-art dust extraction grinder, they significantly reduced the amount of grinding dust released into the air, which led to a cleaner workspace and improved efficiency. The results were staggering; not only did production times decrease, but maintenance costs also plummeted due to less frequent equipment cleaning and repairs.

Their cutting grinder was equipped with advanced filtration technology that captured over 99% of airborne particles, allowing for safer working conditions and compliance with health regulations. Employees reported feeling more energized and focused without the constant irritation caused by airborne dust particles. This success story highlights that investing in effective grinding dust extraction is not just about compliance—it's about cultivating a healthier work environment that ultimately boosts productivity.

Real-World Examples of Improved Safety

Safety is paramount in any workshop setting, especially when dealing with hazardous materials like grinding dust. One notable case involved a small woodworking shop that struggled with respiratory issues among its workers due to inadequate dust extraction systems. After implementing an upgraded cutting grinder paired with superior dust filtration systems, they experienced an immediate reduction in airborne particulates.

Workers reported fewer health complaints and an overall improvement in morale as they felt safer on the job. The shop's owner noted a marked decrease in sick days taken by employees, which translated into higher productivity levels and greater job satisfaction across the board. This case exemplifies how prioritizing effective grinding dust extraction can lead to significant improvements not just for individual health but for overall business performance.

Lessons Learned from Industry Leaders

Industry leaders have long recognized the critical role that efficient dust extraction plays in operational success. One key takeaway from various successful implementations is the importance of selecting the right equipment tailored to specific needs—whether that's portable or stationary systems for different applications within workshops. Companies learned that investing upfront in high-quality dust extraction grinders pays off tremendously over time through reduced health risks and lower maintenance costs.

Moreover, continuous training on maintaining these systems ensures longevity and optimal performance; regular upkeep prevents common issues such as clogging or inefficient filtration from arising unexpectedly. These lessons emphasize that adopting modern technologies is essential for staying competitive while safeguarding worker well-being—proof that smart investments lead to sustainable practices across industries.

[Image description=workers operating machinery with visible grinding processes, efficient ductwork connected to machines capturing fine particles, clean workspace highlighting effective use of dust extraction systems, focus on safety measures like masks], Image name=kiant_machinery_dust_extraction_success, Alt tag=grinding dust extraction system enhancing workplace safety at Kiant Machinery

Conclusion

In the realm of industrial operations, effective dust extraction systems are not just a luxury; they are a necessity. The importance of grinding dust extraction cannot be overstated, as it directly contributes to a safer and healthier working environment. By investing in high-quality dust filtration systems, businesses can significantly reduce health risks associated with airborne particulates while enhancing overall productivity.

Enhancing Safety with Dust Extraction

Dust extraction plays a pivotal role in maintaining safety standards across various industries that involve grinding processes. The presence of fine particles can lead to respiratory issues and other health hazards, making efficient dust extraction essential for worker wellbeing. Implementing advanced dust extraction systems ensures that harmful particles are captured and filtered out, leading to improved air quality and reduced risk of accidents.

Choosing the Best Equipment for Your Needs

Selecting the right equipment is crucial when it comes to optimizing your dust extraction strategy. A cutting grinder equipped with an efficient dust extraction grinder can make all the difference in maintaining cleanliness and safety on the shop floor. It's vital to assess your specific needs—considering factors like portability versus stationary options—as well as comparing brands known for their reliable dust filtration systems before making an investment.

Future Trends in Dust Extraction Systems

The landscape of dust extraction technology is continually evolving, with exciting trends on the horizon that promise even better efficiency and effectiveness. Innovations such as smart sensors and automated cleaning mechanisms are becoming increasingly common in modern dust filtration systems, allowing for real-time monitoring and maintenance alerts. As industries strive for sustainability, we can expect future advancements to focus on eco-friendly materials and energy-efficient designs that enhance both performance and environmental responsibility.