Introduction

Dust might seem harmless, but in the construction industry, it represents a significant challenge that requires serious attention. Understanding OSHA construction dust control regulations is essential for maintaining safety and compliance on job sites. These regulations not only protect workers from health risks but also mitigate the potential for hazardous situations like dust explosion hazards.

Understanding OSHA Dust Regulations

The Occupational Safety and Health Administration (OSHA) has established a framework of dust control regulations aimed at minimizing exposure to harmful particulates in the workplace. These guidelines are designed to help employers implement effective strategies, such as selecting appropriate types of dust collection systems, to ensure a safer working environment. By adhering to these regulations, companies can significantly reduce the risk of incidents related to aluminum dust hazards and other dangerous materials.

Importance of Dust Control in Construction

Effective dust control is critical in construction settings where heavy machinery and various materials generate airborne particles that can harm workers' health. Implementing proper measures not only helps avoid respiratory issues but also enhances productivity by creating a cleaner work environment. Furthermore, understanding whether laser dust is harmful can aid in developing comprehensive safety protocols tailored to specific tasks and equipment used on-site.

Common Misconceptions About Dust Hazards

Many people underestimate the dangers associated with different types of dust found in construction environments, leading to misconceptions about their severity. For instance, some may believe that all dust is benign or that only visible particles pose risks; however, even fine particulate matter can have severe health implications over time. Additionally, misconceptions surrounding heavy equipment air filter cleaning can lead to inadequate maintenance practices that exacerbate exposure levels instead of reducing them.

Overview of OSHA Dust Regulations

Navigating the maze of OSHA dust regulations can feel like trying to find your way through a construction site blindfolded. Yet, understanding these regulations is crucial for maintaining a safe working environment, especially in industries where dust can pose significant hazards. From construction to aerospace, knowing the rules can help mitigate risks associated with dust exposure and potential dust explosion hazards.

Key Standards and Guidelines

OSHA has laid out specific standards and guidelines to address various types of dust hazards, ensuring that employers prioritize worker safety. One key regulation is the Respiratory Protection Standard (29 CFR 1910.134), which mandates protective measures when airborne contaminants exceed permissible exposure limits. Additionally, the General Duty Clause requires employers to provide a workplace free from recognized hazards, including those posed by aluminum dust hazards and other combustible particles.

Understanding these key standards helps organizations implement effective strategies for compliance with OSHA construction dust control regulations. By familiarizing themselves with these guidelines, companies can better protect their workforce from health risks associated with prolonged exposure to harmful dust particles. This proactive approach not only enhances safety but also fosters a culture of responsibility among employees.

OSHA Construction Dust Control Regulations Explained

The OSHA construction dust control regulations are designed specifically to tackle airborne contaminants generated during construction activities. These regulations outline best practices for controlling silica and other hazardous materials that are prevalent on job sites, such as concrete or wood dust. Employers must conduct regular assessments and implement appropriate controls—like employing various types of dust collection systems—to minimize exposure risks.

One common solution is the centralized dust collection system, which efficiently captures airborne particles at their source before they spread throughout the work area. This system significantly reduces the risk of creating an unsafe environment where workers could be exposed to harmful levels of particulate matter or face potential combustion events related to a dust explosion hazard. Compliance with these regulations not only safeguards workers but also aligns businesses with industry standards.

The Role of Compliance in Workplace Safety

Compliance with OSHA’s regulations plays an integral role in fostering workplace safety and health among employees across various industries—including aerospace manufacturing where specialized processes often generate significant amounts of debris and particulate matter requiring effective aerospace dust extraction systems. When companies adhere strictly to these guidelines, they reduce liability risks while enhancing productivity through improved worker morale.

Moreover, understanding whether laser cutting operations produce harmful particulates—such as “is laser dust harmful?”—is vital for ensuring comprehensive safety measures are in place within any organization’s operational framework. Regular training sessions focused on heavy equipment air filter cleaning techniques further empower workers by equipping them with knowledge about best practices for maintaining clean environments free from excessive dust accumulation.

By prioritizing compliance with OSHA construction dust control regulations and investing in appropriate technologies like centralized or localized ventilation systems, employers can create safer workplaces that ultimately lead to healthier outcomes for everyone involved.

Identifying Dust Explosion Hazards

Dust explosion hazards are a serious concern in various industries, particularly those involving construction and manufacturing. These hazards arise when fine dust particles accumulate and become airborne, creating an explosive atmosphere under the right conditions. Understanding what constitutes a dust explosion hazard is crucial for compliance with OSHA construction dust control regulations and ensuring workplace safety.

What Constitutes a Dust Explosion Hazard

A dust explosion hazard occurs when combustible dust particles are suspended in the air at sufficient concentrations, combined with an ignition source such as sparks or heat. The potential for an explosion increases significantly when these conditions align, making it essential to identify areas where such accumulations might occur. Industries must adhere to OSHA construction dust control regulations to mitigate these risks and maintain safe working environments.

To effectively manage these hazards, employers should conduct regular assessments of their facilities to identify areas prone to dust accumulation. Implementing effective types of dust collection systems can significantly reduce the likelihood of a dust explosion by capturing particles before they have a chance to become airborne. By understanding what constitutes a dust explosion hazard, organizations can take proactive steps towards compliance and safety.

Common Types of Dust Hazards in Industries

Various industries face unique challenges related to dust hazards, each requiring tailored approaches to address them effectively. In construction, common types of hazardous materials include wood, concrete, and metal shavings that can generate significant amounts of fine particulate matter during operations. Similarly, manufacturing sectors like food processing or pharmaceuticals encounter specific types of combustible dust that necessitate stringent controls under OSHA construction dust control regulations.

In addition to traditional materials, emerging technologies also present new risks; for instance, laser cutting processes may produce fine debris that raises questions about safety—many wonder: is laser dust harmful? Addressing this concern involves understanding how different materials behave when subjected to high-energy processes and ensuring proper ventilation systems are in place. By recognizing common types of industry-specific dust hazards, companies can better prepare their employees for safe practices.

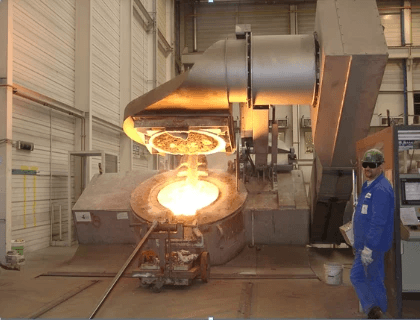

Aluminum Dust Hazards: A Special Case

Aluminum dust presents unique challenges due to its highly combustible nature and propensity for creating explosive atmospheres when finely divided. Industries that work with aluminum must be particularly vigilant about managing aluminum dust hazards through rigorous adherence to OSHA construction dust control regulations. This includes implementing specialized types of dust collection systems designed specifically for metallic powders.

The risk associated with aluminum powder is compounded by its widespread use across various sectors—especially aerospace—where precision manufacturing processes generate significant quantities of fine particles during machining operations. Heavy equipment air filter cleaning becomes paramount in environments where aluminum is processed; neglecting this maintenance can lead directly to dangerous accumulations that pose serious risks not only from explosions but also from respiratory issues among workers exposed over time.

As organizations continue navigating the complexities surrounding aluminum and other hazardous materials, awareness remains key; proactive measures like training workers on effective cleanup methods will help mitigate potential dangers associated with these specialized cases.

Types of Dust Collection Systems

Dust collection systems are essential for maintaining compliance with OSHA construction dust control regulations and ensuring a safe working environment. These systems help mitigate dust exposure risks, particularly in industries where dust explosion hazards are prevalent. Understanding the types of dust collection systems available can significantly impact workplace safety and efficiency.

Centralized Dust Collection System Explained

A centralized dust collection system is a comprehensive solution designed to manage dust from multiple sources across a facility. This system typically consists of ductwork, filters, and a central vacuum unit that collects airborne particles from various locations. By efficiently capturing dust at its source, centralized systems help reduce overall airborne contaminants and maintain compliance with OSHA construction dust control regulations.

These systems are particularly effective in larger operations where numerous machines generate significant amounts of dust, such as woodworking or metalworking shops. However, they require careful planning regarding layout and maintenance to ensure optimal performance. Regular inspections and heavy equipment air filter cleaning are crucial to keep these systems functioning effectively.

Benefits of Local Exhaust Ventilation

Local exhaust ventilation (LEV) is another popular type of dust collection system that targets specific sources of airborne contaminants directly at their origin. LEV systems utilize hoods or enclosures to capture harmful particles before they disperse into the workspace, making them an excellent choice for environments with high concentrations of hazardous materials like aluminum dust hazards.

One significant advantage of LEV is its ability to minimize worker exposure while still allowing for flexibility in work processes. Unlike centralized systems that may require extensive ductwork, LEV can be installed quickly and adjusted as needed based on workflow changes or new equipment introductions—ensuring ongoing compliance with OSHA construction dust control regulations.

Choosing the Right System for Your Needs

Selecting the right type of dust collection system involves assessing your specific operational needs, potential risks associated with various materials (like is laser dust harmful?), and regulatory requirements such as OSHA standards. Factors such as facility size, the nature of work being performed, and existing infrastructure will influence your choice between centralized systems or local exhaust ventilation.

Additionally, consider how your chosen system will address specific hazards like aluminum dust hazards or other combustible materials that pose a risk for explosions if not properly managed. Ultimately, investing time in evaluating your options will lead to better protection for workers while ensuring compliance with safety regulations—because when it comes to workplace safety, one size does not fit all!

Health Risks of Dust Exposure

Dust exposure in various industries, including construction and aerospace, poses significant health risks that can compromise worker safety. Compliance with OSHA construction dust control regulations is crucial to mitigate these dangers effectively. Understanding the different types of dust hazards, such as aluminum dust hazards and laser dust, helps in developing better control measures.

Is Laser Dust Harmful? Understanding Risks

When discussing the safety of laser operations, a common question arises: is laser dust harmful? Yes, it can be hazardous if proper precautions aren’t taken. Laser cutting processes generate fine particulate matter that can become airborne, leading to respiratory issues if inhaled over time—an essential consideration under OSHA construction dust control regulations.

In addition to respiratory concerns, exposure to laser-generated dust may also cause skin irritation or eye damage. Workers need to be informed about the specific risks associated with their tasks and provided with adequate protective equipment. Implementing effective types of dust collection systems tailored for laser applications can significantly reduce these risks.

Long-term Effects of Dust Exposure on Workers

The long-term effects of dust exposure on workers are alarming and often underestimated. Chronic inhalation of hazardous particles can lead to serious health conditions such as chronic obstructive pulmonary disease (COPD), lung cancer, and other respiratory illnesses. This emphasizes the importance of adhering strictly to OSHA construction dust control regulations in every work environment.

Moreover, certain types of dust, like aluminum dust hazards from metalworking processes, pose additional risks due to their potential for explosion—a danger that cannot be overlooked in any industrial setting. The cumulative impact on health from prolonged exposure is a reminder that preventive measures must be prioritized over reactive solutions after incidents occur. By understanding these long-term effects, employers can make informed decisions about investing in effective ventilation systems and employee training programs.

Preventing Respiratory Issues Through Effective Control

Preventing respiratory issues caused by dust exposure requires a multi-faceted approach involving proper training and robust systems for managing airborne particulates. Regular heavy equipment air filter cleaning is vital for maintaining optimal performance and minimizing emissions from machinery used on job sites or in manufacturing plants like aerospace facilities where specialized aerospace dust extraction is often required.

Employers should also invest in centralized dust collection systems that efficiently capture harmful particles at their source before they spread into the workplace environment. Training workers on safe practices related to handling materials known for generating harmful dust—including awareness about aluminum dust hazards—can further enhance safety measures implemented at worksites.

In conclusion, understanding the health risks associated with various forms of industrial dust is paramount for ensuring worker safety and compliance with OSHA standards. By prioritizing effective control measures and educating employees about potential hazards like laser-generated particulates or explosive aluminum particles, organizations can foster a safer working environment while adhering to regulatory requirements.

Best Practices for Dust Control

When it comes to maintaining a safe work environment, especially in construction settings, implementing effective dust control practices is essential. Not only do these practices help comply with OSHA construction dust control regulations, but they also minimize the risk of dust explosion hazards that can arise from various types of dust present on job sites. By focusing on advanced techniques and training, companies can significantly reduce the health risks associated with dust exposure.

Heavy Equipment Air Filter Cleaning Techniques

Heavy equipment air filters play a crucial role in preventing airborne particles from contaminating the workplace environment. Regular cleaning and maintenance of these filters are vital to ensure compliance with OSHA construction dust control regulations and to mitigate potential aluminum dust hazards that may arise during operations. Techniques such as using compressed air or specialized vacuum systems can effectively remove accumulated debris without damaging the filter material, promoting longer-lasting performance.

Moreover, establishing a routine cleaning schedule not only enhances equipment efficiency but also fosters a culture of safety among workers. Keeping heavy equipment in optimal condition reduces downtime and minimizes the risk of respiratory issues caused by inhaling harmful particles. Ultimately, investing time in proper air filter cleaning techniques pays off by ensuring both worker health and regulatory compliance.

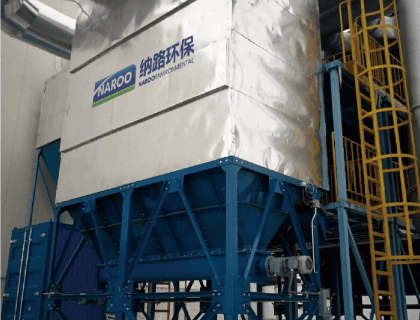

How NAROO Innovates Dust Removal Solutions

In the quest for effective dust control solutions, NAROO has emerged as a leader by developing innovative products tailored to diverse industries including aerospace dust extraction applications. Their cutting-edge designs focus on improving airflow while capturing fine particles that traditional systems might miss, addressing specific challenges like aluminum dust hazards commonly faced in manufacturing environments. This innovation not only helps businesses meet OSHA construction dust control regulations but also enhances overall worker safety.

NAROO's approach emphasizes adaptability; their solutions can be customized based on varying operational needs and space constraints found across different job sites. By integrating advanced filtration technologies into their systems, they provide robust protection against both visible and microscopic particles that pose health risks over time—because who wants to gamble with “is laser dust harmful?” when there’s an efficient solution at hand? With NAROO’s innovations, companies are equipped to tackle even the most stubborn types of dust collection systems challenges.

Training Workers on Safe Dust Management

Training workers is an often-overlooked yet critical aspect of effective dust management strategies within any organization dealing with potential hazards like aluminum or laser-generated dusts. Establishing comprehensive training programs ensures employees understand not just how to operate machinery safely but also how to recognize potential dangers associated with various types of dust exposure—especially those related to OSHA construction dust control regulations compliance requirements.

Regular workshops can cover topics ranging from identifying common sources of hazardous materials to implementing best practices for maintaining clean workspaces through proper use of centralized dust collection systems or local exhaust ventilation setups. Empowering workers with knowledge ultimately leads to enhanced vigilance against possible incidents such as explosions caused by flammable particulates—a serious concern when dealing with certain types of industrial operations.

In conclusion, fostering a culture centered around safe practices through diligent training creates an environment where everyone is aware and proactive about managing risks associated with airborne contaminants effectively.

Conclusion

In the realm of construction and various industries, adherence to OSHA construction dust control regulations is not just a bureaucratic formality; it’s a fundamental aspect of ensuring worker safety and health. These regulations help mitigate risks associated with dust exposure, including the potential for a dust explosion hazard that can lead to catastrophic outcomes. By prioritizing compliance, businesses not only protect their workforce but also enhance their operational integrity.

The Importance of Compliance with OSHA Regulations

Compliance with OSHA construction dust control regulations is essential for maintaining a safe working environment. These regulations provide clear guidelines on how to manage and minimize dust exposure, which can otherwise lead to severe health issues like respiratory problems or even explosions from combustible dusts such as aluminum dust hazards. Companies that take these regulations seriously are investing in the well-being of their employees while also safeguarding their business from legal repercussions.

Future Trends in Dust Control Technology

As we look toward the future, advancements in dust collection systems are set to revolutionize how industries approach air quality management. Innovations such as smart centralized dust collection systems will allow for more efficient monitoring and control of airborne particles, making compliance with OSHA construction dust control regulations simpler than ever. Furthermore, emerging technologies will address specific challenges like whether laser dust is harmful by providing real-time data on particulate sizes and concentrations.

Ensuring Safety in Construction and Beyond

Ensuring safety extends beyond just adhering to regulations; it involves fostering a culture of awareness around hazards such as aluminum dust hazards or other types of airborne contaminants. Training workers on heavy equipment air filter cleaning techniques and effective use of various types of dust collection systems will empower them to take an active role in maintaining workplace safety. As industries evolve, integrating aerospace dust extraction methods into standard practices could further enhance safety measures across all sectors, creating healthier work environments for everyone involved.