Introduction

In the world of industrial air filtration, dust collector troubleshooting can often feel like navigating a maze. With numerous challenges and potential pitfalls, understanding the intricacies of dust collection systems is crucial for maintaining optimal performance. This guide will delve into common issues encountered in air filtration, such as low suction power, particulate bypassing filters, and consistently clogged filters, while emphasizing the importance of proper maintenance to keep your systems running smoothly.

Understanding Dust Collector Challenges

Dust collectors are essential for ensuring clean air in industrial environments, but they come with their own set of challenges. Problems like Industrial Air Filter Systems With Little or No Suction can lead to inefficiencies that compromise air quality and operational productivity. Recognizing these challenges is the first step toward effective dust collector troubleshooting; knowing what to look for helps prevent minor issues from escalating into major headaches.

Common Issues Encountered in Air Filtration

When it comes to air filtration systems, several common issues frequently arise that can hinder performance. From zero-pressure differential readings from the air filtration system to signs of a particulate bypassing air filter, these problems can significantly impact both safety and efficiency. By familiarizing yourself with these typical concerns, you empower yourself to tackle them head-on before they spiral out of control.

Importance of Proper Maintenance

Proper maintenance is not just a suggestion; it's an absolute necessity for any effective dust collector system. Regular check-ups and timely interventions can prevent consistently clogged filters and ensure that your air filtration system is not pulsing as it should be. In this guide, we’ll explore best practices that will help you maintain efficient air filtration systems while minimizing downtime and costly repairs.

Industrial Air Filter Systems With Little or No Suction

When dealing with industrial air filter systems, low suction power can be a significant headache. This issue often leads to inefficient dust collection and compromises air quality, making it crucial to address promptly. In this section of our dust collector troubleshooting guide, we will explore the causes of low suction power, identify affected components, and offer solutions for restoring airflow.

Causes of Low Suction Power

Low suction power in industrial air filter systems can arise from various factors that hinder optimal performance. One common culprit is a clogged or dirty filter, which can lead to restricted airflow and decreased efficiency in dust collection. Additionally, leaks in ductwork or improper installation can contribute to diminished suction power, allowing particulates to bypass the air filter and negatively impact overall system function.

Another reason for low suction may be related to fan issues; if the fan is malfunctioning or not operating at the required speed, it won't generate adequate airflow. Equipment wear and tear over time can also lead to reduced performance levels that affect suction capabilities. Understanding these causes is essential for effective troubleshooting in your dust collector system.

Identifying System Components Affected

To tackle low suction effectively, it's important first to identify which components of your air filtration system are affected by this issue. Start by checking the filters; if they are consistently clogged or dirty, they could be preventing proper airflow through the system. Next, inspect ductwork for any leaks or obstructions that may be diverting airflow away from intended areas.

The fan is another critical component worth examining—ensure it operates smoothly without any unusual noises that might indicate mechanical failure. Lastly, consider evaluating any dampers or valves within the system; if they're not functioning correctly, they could disrupt proper airflow and exacerbate low suction problems. By pinpointing these affected components early on, you can streamline your troubleshooting efforts.

Solutions for Restoring Airflow

Once you've identified the sources of low suction power in your industrial air filter systems with little or no suction, it's time to implement effective solutions aimed at restoring airflow. Start by replacing clogged filters with new ones designed specifically for your equipment; regular maintenance checks will help prevent future clogs from occurring as well as ensure optimal performance.

Next up: seal any leaks found in ductwork using appropriate materials such as mastic sealant or metal tape—this simple fix can significantly improve your system's efficiency! If fan issues persist even after maintenance checks and adjustments have been made, consider consulting a professional technician who specializes in dust collector troubleshooting guide practices tailored specifically for industrial settings.

Lastly, don't overlook the importance of routine inspections and cleaning schedules; staying proactive about maintaining your filtration system will help avoid recurring problems like consistently clogged filters or zero-pressure differential readings from the air filtration system down the line!

Particulate Bypassing Air Filter

When it comes to maintaining effective air quality in industrial settings, one of the most pressing issues is the phenomenon of particulate bypassing the air filter. This occurs when dust and other particulates manage to slip past the filter, leading not only to compromised air quality but also potential operational inefficiencies. Understanding how to identify and fix this issue is crucial for anyone relying on a robust dust collector troubleshooting guide.

Signs of a Bypassing Filter

Recognizing a bypassing filter can save you from larger problems down the line. Common signs include visible dust accumulation in areas that should be clean, unusual spikes in equipment wear, or unexpected increases in maintenance costs. If your air filtration system is not pulsing as it should or if you’re noticing zero-pressure differential readings from the air filtration system, these could all indicate that particulates are making their way through undetected.

Impact on Air Quality and Operations

The impact of a bypassing filter extends far beyond aesthetics; it can significantly affect both air quality and overall operations. Poor air quality can lead to health risks for employees and environmental compliance issues for your facility. Moreover, if your industrial air filter systems with little or no suction are allowing particulates to escape, you may find yourself facing increased downtime due to equipment malfunctions or even costly repairs.

Fixing the Bypass Problem

To tackle the bypass problem effectively, start by inspecting your filters for any signs of damage or improper installation—these are often culprits in allowing particles to escape unnoticed. Regular maintenance practices like cleaning clogged filters can help maintain optimal airflow and prevent future issues with consistently clogged filters. Additionally, consider upgrading your filtration technology; modern solutions designed specifically for high-efficiency particulate matter (HEPA) capture can make a world of difference in ensuring that your dust collector troubleshooting guide remains effective.

Consistently Clogged Filters

Consistently clogged filters can be a persistent headache for any facility relying on effective air filtration systems. This issue not only hampers the efficiency of dust collectors but also compromises air quality, leading to potential operational disruptions. Understanding why filters clog repeatedly is crucial in implementing a dust collector troubleshooting guide that addresses the root causes and enhances overall performance.

Why Filters Clog Repeatedly

There are several reasons why filters in industrial air filter systems may clog consistently, often leading to low suction power and reduced airflow. One common culprit is the presence of high levels of particulate matter in the environment, which overwhelms the filter's capacity to capture contaminants effectively. Additionally, inadequate maintenance routines or using filters not suited for specific applications can exacerbate this problem, leading to frequent blockages.

Another factor contributing to repeated clogging is improper installation or configuration of the air filtration system itself. If components such as ductwork aren't optimized for airflow, it can create turbulence that forces particles into the filter more aggressively than intended. Lastly, environmental conditions like humidity and temperature fluctuations can affect filter performance; moisture can cause particles to clump together, making them harder to capture and increasing clogging rates.

Maintenance Best Practices

To combat consistently clogged filters effectively, adopting robust maintenance best practices is essential for any facility utilizing an air filtration system. Regular inspections should be scheduled to assess filter conditions and identify early signs of wear or blockage before they escalate into bigger issues—this proactive approach aligns with your dust collector troubleshooting guide's recommendations. Additionally, ensuring proper sealing around filters will help maintain optimal airflow and reduce bypassing issues associated with particulate bypassing air filters.

It's also vital to establish a cleaning schedule based on your facility’s unique operating conditions—frequent cleaning may be necessary in environments with high dust levels while less frequent cleaning might suffice elsewhere. Using appropriate tools such as compressed air or specialized vacuum systems designed for filter maintenance will enhance cleaning effectiveness without damaging delicate media structures within your filters.

Finally, training staff on proper handling techniques during maintenance activities ensures that everyone understands how crucial their role is in maintaining efficient operations within industrial air filter systems with little or no suction power due to clogged filters.

Techniques for Effective Cleaning

Effective cleaning techniques are paramount when dealing with consistently clogged filters in your air filtration system—after all, a clean filter is a happy filter! One popular method involves backwashing or reverse pulse jet cleaning; this technique uses bursts of compressed air directed against the filter media to dislodge accumulated particulates without physically removing it from its housing—a real time-saver!

Another effective approach includes using vibration-based cleaners that shake off debris from the surface of the filter material; this method works wonders when combined with regular inspections outlined in your dust collector troubleshooting guide since it allows you to address issues before they become problematic. Moreover, consider investing in automated monitoring systems that continually assess pressure differentials across your filtration units—these smart solutions help alert you when clogging occurs so you can act swiftly before zero-pressure differential readings from the air filtration system become an issue.

Lastly, don’t underestimate good old-fashioned manual cleaning! Utilizing soft brushes or cloths specifically designed for filtering material will keep surfaces free from stubborn deposits while extending their lifespan significantly—because nobody wants another frustrating day dealing with clogged filters!

Zero-Pressure Differential Reading From The Air Filtration System

When it comes to dust collector troubleshooting, one of the most perplexing issues is a zero-pressure differential reading from the air filtration system. This condition indicates that there is no pressure difference between the inlet and outlet of the filter, which can lead to inadequate airflow and reduced efficiency in dust collection. Understanding why this happens is crucial for maintaining optimal performance in industrial air filter systems.

Understanding Pressure Differential Importance

The pressure differential is a key indicator of how well your air filtration system is performing. It helps assess whether your filters are functioning correctly and if there’s enough suction to capture particulate matter effectively. Low or zero-pressure readings can signal issues like clogged filters or leaks, which could lead to problems such as particulate bypassing air filters and inconsistent suction power.

Monitoring the pressure differential regularly can save time and money by preventing larger issues down the road. If you notice a significant drop in pressure, it’s time to take action before your dust collector becomes less effective at its job. Remember, a well-functioning industrial air filter system relies on maintaining an appropriate pressure differential for optimal operation.

Diagnosing Pressure Issues

Diagnosing why you have a zero-pressure differential reading involves several steps that require careful observation and analysis. Start by checking all components of your air filtration system; look for any signs of leaks, blockages, or damaged parts that could disrupt airflow. Additionally, ensure that your filters aren’t consistently clogged—this could be due to poor maintenance practices or using incorrect filter types for your application.

Another common culprit behind pressure issues is improper installation of components within the system itself; even slight misalignments can create significant airflow problems. Utilize tools such as manometers or digital gauges to measure pressure accurately at various points in the system for a thorough diagnosis. If you detect inconsistencies during this assessment, it may be time to consult a dust collector troubleshooting guide for further insights.

Corrective Actions for Pressure Problems

Once you've diagnosed the root cause of zero-pressure differential readings, it's essential to implement corrective actions promptly to restore proper function in your air filtration system. Begin with replacing or cleaning any consistently clogged filters; this simple step often resolves many airflow issues while enhancing overall efficiency in dust collection processes. Additionally, inspect ductwork and connections thoroughly—tightening loose fittings or sealing leaks can significantly improve suction power.

If you discover that certain components are damaged beyond repair, replacing them may be necessary to prevent future problems related to low suction power or inefficient particulate capture capabilities. Regular maintenance should also include scheduled inspections as part of best practices outlined in comprehensive dust collector troubleshooting guides available online or through industry resources like NAROO experts specializing in these systems.

By taking these corrective actions seriously and adhering closely to maintenance schedules, you'll not only enhance performance but also extend the lifespan of your industrial air filter systems with little or no suction.

Air Filtration System Is Not Pulsing

When an air filtration system fails to pulse, it can lead to significant issues in dust collection efficiency and overall air quality. This lack of pulsing action is often a symptom of underlying problems that require immediate attention. Understanding the reasons behind this malfunction is crucial for effective dust collector troubleshooting.

Reasons for Lack of Pulsing Action

Several factors can contribute to an air filtration system not pulsing as it should. One common culprit is a malfunctioning solenoid valve, which controls the airflow and timing of the pulses; if it's stuck or damaged, you might find your system in a state of limbo. Additionally, issues such as low-pressure differentials or electrical problems within the control panel can disrupt the normal operation, leading to stagnant filtration processes.

Another reason could be related to particulate bypassing air filters; when filters are saturated with dust, they may not allow for proper airflow dynamics necessary for pulsing action. If you’ve been dealing with consistently clogged filters in your system, this could also impact the ability to generate sufficient pressure needed for effective pulsing. Ultimately, recognizing these indicators early on can save time and money when addressing these industrial air filter systems with little or no suction.

Effects on Dust Collection Efficiency

The absence of pulsing in an air filtration system directly impacts its dust collection efficiency, leading to subpar performance and potentially hazardous working conditions. Without proper pulsation, accumulated dust can remain trapped in filters longer than necessary, causing increased resistance and reduced airflow through the system over time. This scenario not only diminishes overall operational effectiveness but also leads to higher energy consumption as fans work harder against clogged pathways.

Moreover, inadequate cleaning cycles due to non-pulsing action contribute to particulate bypassing air filters; this means that particles escape into the environment instead of being captured effectively by the filtration system. Consequently, businesses may face compliance issues regarding air quality standards while exposing employees to harmful airborne contaminants—definitely not ideal! In summary, ensuring that your filtration system pulses correctly is vital for maintaining high levels of efficiency and safety.

Steps to Restore Normal Function

To restore normal function in an air filtration system that isn't pulsing properly requires a systematic approach involving thorough inspection and maintenance practices outlined in any comprehensive dust collector troubleshooting guide. Start by examining the solenoid valve—check if it's functioning correctly or needs replacement; sometimes a simple cleaning might do wonders! Next up is assessing electrical connections; loose wires or faulty controls could easily be behind your troubles.

If those checks don’t yield results, consider evaluating pressure differentials across your filters using tools designed for zero-pressure differential readings from the air filtration system—this will help pinpoint any blockages or leaks affecting performance. Lastly, regular maintenance practices should be implemented moving forward; ensure that filter replacements occur timely and that cleaning schedules are adhered to avoid recurrent issues like consistently clogged filters down the line! By following these steps diligently, you’ll have your industrial air filter systems back on track before you know it.

Conclusion

In the world of industrial air filtration, a well-maintained dust collector is essential for optimal performance and air quality. This dust collector troubleshooting guide has highlighted common issues such as low suction power, particulate bypassing filters, consistently clogged filters, zero-pressure differential readings, and non-pulsing systems. By recognizing these problems early and implementing effective solutions, you can ensure your air filtration systems operate at peak efficiency.

Key Takeaways from Dust Collector Troubleshooting

Understanding the nuances of dust collector troubleshooting is crucial for maintaining an efficient system. From identifying causes of low suction in Industrial Air Filter Systems With Little or No Suction to recognizing the signs of a Particulate Bypassing Air Filter, being proactive can save both time and money. Remember that consistently clogged filters not only hinder performance but also compromise air quality; addressing these issues promptly is key to successful operations.

Maintaining Efficient Air Filtration Systems

Regular maintenance is the backbone of any reliable air filtration system. Implementing best practices helps prevent issues like zero-pressure differential readings from the air filtration system and ensures that your equipment remains functional over time. Techniques for effective cleaning are vital in combating challenges such as consistently clogged filters and ensuring that your Air Filtration System Is Not Pulsing when it should be.

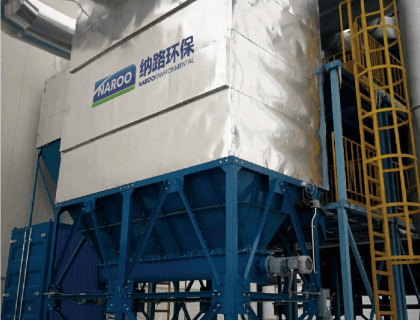

Working with NAROO for Reliable Solutions

When faced with persistent challenges in dust collection, partnering with experts like NAROO can provide invaluable support. Their expertise ensures that you receive tailored solutions to address specific problems outlined in this dust collector troubleshooting guide, whether it’s restoring suction power or fixing bypass issues effectively. Trusting professionals who understand the intricacies of industrial air filter systems will help maintain optimal performance and extend the lifespan of your equipment.