Introduction

In the realm of industrial dust collection, understanding cyclone separators is pivotal. These ingenious devices are engineered to efficiently separate particulate matter from air or gas streams, making them essential in various industries. By harnessing the power of centrifugal force, an industrial cyclone separator can significantly enhance operational efficiency and air quality.

Understanding Cyclone Separators

So, what is a cyclone separator used in industry? Essentially, it's a mechanical device that employs a swirling motion to segregate dust and other particles from airflow. This process not only streamlines production but also ensures compliance with health and environmental regulations, showcasing the versatility of these remarkable machines.

Benefits for Industrial Dust Collection

The benefits of using an industrial cyclone for dust collection are manifold. For starters, they offer high efficiency in capturing airborne particles while minimizing energy consumption. Moreover, industries such as food and pharmaceuticals rely on cyclone separators to maintain cleanliness and safety standards—vital for product integrity and consumer health.

NAROO's Role in the Industry

NAROO has positioned itself as a key player in the cyclone separator market with its innovative Cyclone Dust Separator Kit. This kit exemplifies cutting-edge technology tailored to meet diverse industrial needs—from enhancing productivity to ensuring environmental compliance. With case studies showcasing successful implementations across sectors like food processing and pharmaceuticals, NAROO is redefining what it means to invest in sustainable industrial practices.

What is a Cyclone Separator?

When it comes to dust collection in various industries, the industrial cyclone separator stands out as a robust solution. This device utilizes centrifugal force to separate particles from air or gas streams, making it an essential component in maintaining clean working environments. But what exactly is a cyclone separator used in industry? Let’s dive into its definition, types, and applications.

Definition and Function

At its core, a cyclone separator is a mechanical device designed to remove particulate matter from an air or gas stream through the process of cyclonic separation. The basic function involves drawing in air laden with dust and debris, which then spirals through the separator. As the airflow changes direction within the chamber, heavier particles are thrown against the walls and fall into a collection bin while cleaner air exits through the top—this is the cyclone separator working principle that makes it so effective.

Types of Cyclone Separators

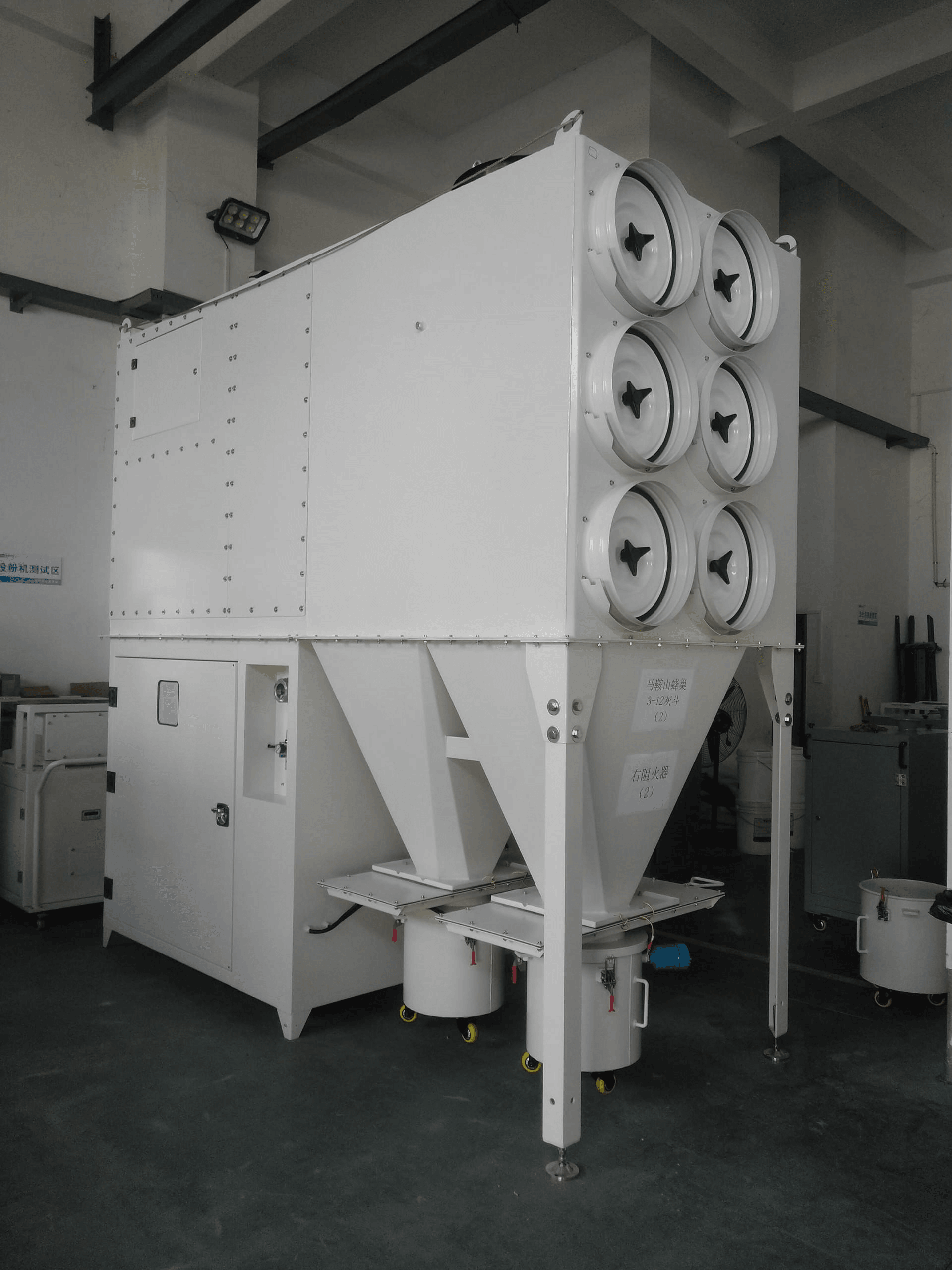

There are several types of cyclone separators tailored for specific industrial needs, including single-cyclone units and multi-cyclone configurations. Single-cyclone separators are typically used for smaller operations where space is limited but still require efficient dust removal. On the other hand, multi-cyclone separators can handle larger volumes of air and are often employed in heavy-duty applications across various sectors such as food processing or pharmaceuticals.

Common Applications

Cyclone separators find their way into many industries due to their versatility and efficiency. In the food industry, for instance, they help maintain product purity by removing contaminants from processed air streams—what is a cyclone separator in the food industry if not an essential safeguard? Similarly, in pharmaceutical settings, these devices ensure that airborne particulates do not compromise product quality; what are cyclone separators used in the pharmaceutical industry for if not protecting health standards? Overall, whether it's food production or chemical processing, industrial cyclone separators play a crucial role across diverse applications.

Cyclone Separator Working Principle

Understanding the working principle of an industrial cyclone separator is crucial for grasping its effectiveness in various applications. At its core, a cyclone separator utilizes the force of centrifugal motion to separate particles from a gas or liquid stream. This method is not only efficient but also versatile, making it an essential component in industries ranging from food processing to pharmaceuticals.

How Airflow Influences Separation

Airflow plays a pivotal role in the separation process within an industrial cyclone separator. The design of the separator allows air to enter at a specific angle, creating a swirling motion that helps to separate heavier particles from lighter ones. The speed and direction of this airflow dictate how effectively dust and debris are collected, which is why understanding airflow dynamics is key to optimizing performance.

In many applications, such as those found in the food industry, controlling airflow can mean the difference between effective dust collection and inefficient operation. When properly tuned, this airflow not only enhances separation efficiency but also reduces wear on equipment—leading to longer service life and lower maintenance costs. So whether you’re asking What is a cyclone separator used in industry? or looking for solutions like the Cyclone Dust Separator Kit, remember that mastering airflow is fundamental.

The Science Behind Cyclonic Action

The science behind cyclonic action involves principles of physics that govern how particles behave when subjected to rapid spinning motions. As air enters an industrial cyclone at high velocity, it creates a vortex that forces heavier particles outward toward the walls of the separator while allowing lighter particles to pass through more easily. This phenomenon results in effective particle separation without needing complex filtration systems.

In industries such as pharmaceuticals, where cleanliness and precision are paramount, understanding cyclonic action becomes even more critical. Cyclone separators can efficiently remove contaminants without introducing additional complexities into the system—making them ideal for maintaining stringent quality standards. Thus, when considering What are cyclone separators used in the pharmaceutical industry for?, it's clear they play an essential role in ensuring product integrity.

Key Components in Operation

An industrial cyclone separator consists of several key components that work together seamlessly during operation. These include an inlet duct where air enters, a cylindrical body where separation occurs, and a cone-shaped bottom where collected materials accumulate before being discharged. Each component must be designed with care to ensure optimal performance and longevity.

Additionally, auxiliary features like dust hoppers or discharge valves may be included depending on specific applications—such as those seen with What is a cyclone separator in the food industry? Here too, design considerations ensure that food safety standards are met while maximizing efficiency during production processes. Understanding these components provides insights into why investing in solutions like NAROO's Cyclone Dust Separator Kit can lead to significant improvements across various sectors.

Cyclone Separators in Various Industries

Cyclone separators are versatile tools that find applications across multiple sectors, each benefiting from their unique design and efficiency. Understanding how these industrial cyclone separators operate can illuminate their critical roles in diverse industries, from food processing to pharmaceuticals and heavy manufacturing. Let’s explore the specific uses of cyclone separators in these fields.

Food Industry Applications

In the food industry, what is a cyclone separator used for? These devices are essential for maintaining hygiene and product quality by efficiently collecting dust and contaminants during processing. For instance, they can separate flour dust from air in milling operations or remove excess powder from ingredients in snack production lines, ensuring compliance with health regulations.

The cyclone separator working principle relies on centrifugal force to separate particles from the airflow, making it an ideal choice for handling dry materials without compromising their integrity. Additionally, what is a cyclone separator in the food industry? It helps prevent contamination and ensures that products meet safety standards while optimizing operational efficiency.

With NAROO's Cyclone Dust Separator Kit specifically designed for food applications, manufacturers can enhance cleanliness and productivity simultaneously. This kit not only boosts dust collection but also contributes to a safer working environment by minimizing airborne particles that could affect both workers and products.

Pharmaceutical Industry Utilization

In the pharmaceutical sector, maintaining stringent quality control is paramount; hence, what are cyclone separators used in the pharmaceutical industry for? They serve as effective solutions for collecting fine powders during drug formulation processes while ensuring that no harmful contaminants enter the final product. Their ability to operate without additional moving parts reduces contamination risk significantly.

The industrial cyclone separator’s efficiency aligns perfectly with Good Manufacturing Practices (GMP), which require clean environments free of particulate matter. By employing these separators, companies can adhere to regulatory standards while enhancing productivity through reliable dust collection methods.

Moreover, understanding how the cyclone separator working principle applies here is crucial; it utilizes high-speed rotation to segregate particles based on size and density effectively. This capability allows pharmaceutical manufacturers to maintain high levels of purity throughout production cycles while optimizing resource usage.

Heavy Industry Implementations

Heavy industries such as mining or construction generate significant amounts of dust and debris; therefore, implementing an industrial cyclone becomes essential for effective dust management strategies. What is an industrial cyclone? It refers to robust systems designed specifically for separating larger particles from air streams generated during heavy-duty operations.

These separators play a vital role in improving workplace safety by reducing airborne pollutants that could pose health risks to workers operating heavy machinery or performing manual tasks outdoors. Furthermore, using an industrial cyclone separator minimizes equipment wear caused by abrasive dust accumulation—extending machinery lifespan significantly.

In addition to enhancing safety measures within heavy industries, NAROO's Cyclone Dust Separator Kit proves invaluable by providing tailored solutions that meet specific operational needs across various applications—from quarrying activities to metalworking processes—ensuring optimal performance at all times.

Advantages of Using an Industrial Cyclone Separator

When it comes to industrial dust collection, the advantages of using an industrial cyclone separator are hard to overlook. These systems are not only efficient in capturing dust and particulates but also offer a host of other benefits that make them indispensable in various industries. From cost savings to environmental compliance, let’s dive into why these separators are the unsung heroes of industrial operations.

Efficiency in Dust Collection

One of the standout features of an industrial cyclone separator is its remarkable efficiency in dust collection. Utilizing the cyclone separator working principle, these devices create a powerful vortex that effectively separates dust particles from the air stream. This means that industries can maintain cleaner environments while ensuring compliance with health and safety regulations.

In sectors like food processing and pharmaceuticals, where cleanliness is paramount, understanding what is a cyclone separator used in industry becomes crucial. Cyclone separators can handle large volumes of air with minimal energy consumption, making them a preferred choice for many applications. Whether you're asking what is a cyclone separator in the food industry or what are cyclone separators used in the pharmaceutical industry for, rest assured they provide robust solutions for maintaining air quality.

Cost-Effectiveness and Maintenance

Cost-effectiveness is another compelling advantage offered by industrial cyclone separators. Unlike traditional filtration systems that require frequent replacements or extensive maintenance, cyclones operate efficiently with minimal upkeep. This translates to lower operational costs over time, allowing businesses to allocate resources more effectively.

Moreover, their simple design means fewer moving parts and longer lifespans compared to other dust collection methods. Industries looking for reliable solutions often ask themselves: What is an industrial cyclone? The answer lies in its ability to deliver high performance without breaking the bank on maintenance expenses or replacement parts.

Environmental Impact and Compliance

The environmental impact of using an industrial cyclone separator cannot be overstated; these devices contribute significantly to sustainable practices within various sectors. By efficiently capturing airborne particulates before they escape into the atmosphere, cyclones help organizations comply with stringent environmental regulations while promoting cleaner air quality.

For companies focused on sustainability initiatives, investing in solutions like NAROO's Cyclone Dust Separator Kit can be a game changer. With increasing scrutiny on emissions and waste management practices across industries—especially food and pharmaceuticals—understanding what is an industrial cyclone becomes essential for future-proofing operations against regulatory changes.

NAROO's Cyclone Dust Separator Kit

NAROO's Cyclone Dust Separator Kit stands out in the market for its innovative design and exceptional performance. This kit is engineered to optimize the dust collection process, making it an essential tool for various industries. With a focus on efficiency and sustainability, NAROO has created a product that meets the diverse needs of industrial applications.

Features and Specifications

The NAROO Cyclone Dust Separator Kit boasts an impressive array of features that enhance its functionality in industrial settings. It includes a robust construction designed to withstand harsh conditions, ensuring durability over time. The kit also integrates advanced airflow dynamics, which leverage the cyclone separator working principle to maximize dust separation efficiency while minimizing energy consumption.

In addition to its sturdy build, this industrial cyclone separator is equipped with adjustable inlet sizes, allowing it to accommodate different types of machinery and processes seamlessly. The compact design ensures easy installation without taking up excessive space in your facility. Furthermore, it comes with clear specifications regarding airflow rates and dust capacity, making it easier for users to understand what is required for optimal performance.

Case Studies of Successful Implementations

NAROO’s Cyclone Dust Separator Kit has been successfully implemented across various industries, showcasing its versatility as an industrial cyclone separator. In one notable case within the food industry, a major processing plant reported a significant reduction in airborne particulates after installing the kit. This improvement not only enhanced air quality but also ensured compliance with health regulations—a win-win situation!

In another instance involving pharmaceutical manufacturing, clients noted how the cyclone separator improved their production efficiency by effectively removing fine powders from the air stream during tablet production processes. The result was cleaner work environments and reduced downtime due to equipment clogs caused by dust accumulation—proving that investing in this technology pays off! These case studies exemplify how NAROO’s solutions are tailored to meet specific industry demands while delivering outstanding results.

Testimonials from Satisfied Clients

Clients across various sectors have expressed their satisfaction with NAROO's Cyclone Dust Separator Kit through glowing testimonials highlighting its impact on their operations. One client from a textile manufacturing company remarked on how they noticed immediate improvements in air quality after implementing this industrial cyclone separator; they could breathe easier knowing their employees were less exposed to harmful dust particles.

Another satisfied client from the food industry shared that using this cyclone separator has streamlined their cleaning processes significantly—saving both time and labor costs! They appreciated how effective it was at capturing flour particles during production runs without any loss of efficiency or product integrity. Such positive feedback underscores not only the effectiveness of NAROO's products but also their commitment to enhancing operational excellence across industries.

Conclusion

In summary, industrial cyclone separators are pivotal in enhancing air quality across various sectors. Their ability to effectively separate dust and particulate matter not only improves workplace environments but also aligns with regulatory compliance. As industries continue to prioritize clean air initiatives, the relevance of cyclone technology will only grow.

Enhancing Air Quality with Cyclone Technology

Cyclone separators play a crucial role in maintaining air quality by efficiently capturing airborne particles before they can pollute the environment. In the food industry, for example, what is a cyclone separator used in industry? It serves to ensure that production areas remain free from contaminants, safeguarding both product integrity and consumer health. By utilizing the cyclone separator working principle—where centrifugal force separates dust from airflow—industries can achieve cleaner operations and healthier workplaces.

The Future of Dust Collection Solutions

Looking ahead, the future of dust collection solutions is bright with advancements in cyclone technology on the horizon. As industries evolve, so too will their needs for efficient systems like an industrial cyclone that can adapt to changing regulations and operational demands. The development of innovative products such as NAROO's Cyclone Dust Separator Kit exemplifies how companies are investing in smarter solutions that enhance performance while reducing environmental impact.

Investing in Sustainable Industrial Practices

Investing in sustainable industrial practices is not just a trend; it's becoming a necessity for businesses aiming to thrive in today's eco-conscious market. What are cyclone separators used in the pharmaceutical industry for? They help maintain stringent cleanliness standards while minimizing waste and energy consumption during production processes. By adopting technologies like industrial cyclone separators, organizations demonstrate their commitment to sustainability while reaping long-term benefits through cost-effectiveness and compliance with environmental regulations.