Introduction

In the bustling world of industrial manufacturing, efficient dust management is not merely a preference; it’s a necessity. The accumulation of aluminum dust poses significant risks, including health hazards and potential explosions, making the implementation of a robust dust collection system essential. An aluminum dust collector is designed to mitigate these risks, ensuring both safety and operational efficiency in various industrial applications.

Importance of Efficient Dust Management

Effective dust collection is critical for maintaining a clean and safe working environment. Not only does it protect workers from harmful inhalation of particles, but it also prevents machinery from malfunctioning due to excessive buildup. A well-designed dust collection system enhances productivity by minimizing downtime caused by maintenance issues related to dust accumulation.

Understanding Explosion Proof Technology

Explosion proof technology plays a pivotal role in industries where flammable materials are present, such as aluminum dust. This technology involves specialized equipment designed to contain any sparks or flames that may occur during operation, thus preventing potentially catastrophic explosions. By integrating explosion-proof features into an aluminum dust collector, businesses can significantly reduce the risk associated with handling combustible materials.

Overview of Aluminum Dust Hazards

Aluminum dust is not just an innocuous byproduct; it carries inherent dangers that can lead to severe consequences if left unmanaged. Fine particles can easily ignite when exposed to heat or sparks, resulting in explosive reactions that threaten both personnel and property. Understanding these hazards underscores the necessity for effective dust separation techniques and high-performance dust vacuum systems tailored specifically for handling aluminum particulates.

What is an Aluminum Dust Collector?

When it comes to maintaining a safe and efficient workspace, an aluminum dust collector is a crucial component of any dust collection system. These specialized machines are designed specifically to manage the unique challenges posed by aluminum dust, which can be highly combustible and hazardous if not properly controlled. In essence, an aluminum dust collector works tirelessly to ensure that your environment remains clean and compliant with safety standards.

Defining an Aluminum Dust Collector

An aluminum dust collector is a type of industrial dust collection equipment specifically engineered to capture and filter fine particles generated during the machining, grinding, or cutting of aluminum materials. Unlike standard dust collectors, these systems are built with features that address the specific properties of aluminum dust—like its flammability—ensuring safe handling and disposal. Essentially, they act as the first line of defense in preventing explosive atmospheres while maintaining optimal air quality in industrial settings.

Key Features and Benefits

One of the standout features of an aluminum dust collector is its ability to provide efficient dust separation through advanced filtration technologies that trap even the smallest particles. This not only enhances air quality but also extends the lifespan of machinery by preventing abrasive particles from accumulating on equipment surfaces. Additionally, many models come equipped with powerful dust vacuum systems that facilitate easy maintenance and ensure consistent performance—making them indispensable for any industrial operation dealing with aluminum.

The benefits don't stop there; investing in a high-quality collector dust system can lead to significant cost savings over time by reducing downtime due to equipment failure caused by excessive buildup of harmful particulates. Furthermore, these systems contribute significantly to workplace safety by minimizing fire risks associated with combustible metal powders—a key consideration for any responsible business owner.

Industrial Applications of Dust Collectors

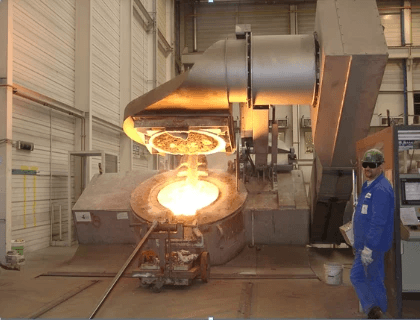

Aluminum dust collectors find their place across various industrial applications where aluminum processing occurs—from aerospace manufacturing facilities to automotive assembly lines. In environments where precision machining takes center stage, these collectors ensure that workers remain safe while enhancing productivity through effective particulate management. Whether it's milling parts or fabricating components, having a reliable dust collection industrial system in place is essential for compliance with health regulations and operational efficiency.

Moreover, industries such as construction and metalworking also benefit from specialized aluminum dust collectors tailored for specific tasks like sanding or welding operations involving aluminum materials. The versatility offered by these machines makes them invaluable assets across multiple sectors where managing fine particulate matter is critical for both safety and performance.

The Need for Explosion Proof Dust Collectors

Aluminum dust, often generated during machining and fabrication processes, poses significant hazards due to its flammability and potential for explosive reactions when suspended in air. A proper dust collection system is essential not just for maintaining a clean workspace but also for ensuring safety and compliance with industry standards.

Recognizing the Risks of Aluminum Dust

Aluminum dust can be deceptively benign in appearance, but its dangers are very real. When aluminum particles are airborne, they can ignite easily under certain conditions, leading to catastrophic explosions that can endanger lives and property. Implementing an effective aluminum dust collector is crucial in mitigating these risks by capturing and containing hazardous particles before they become a threat.

The accumulation of aluminum dust not only increases the risk of explosions but also contributes to respiratory problems among workers if inhaled over time. Therefore, regular maintenance of your dust collection industrial systems is vital to prevent any build-up that could lead to dangerous situations. Awareness and proactive measures are key components in recognizing the inherent risks associated with aluminum dust.

Explosion Prevention and Safety Standards

To combat the dangers posed by aluminum dust, various safety standards have been established by organizations such as OSHA (Occupational Safety and Health Administration) and NFPA (National Fire Protection Association). These standards outline specific requirements for explosion proof systems designed to handle combustible materials safely within industrial settings. Compliance with these regulations not only protects employees but also minimizes liability risks for businesses.

An explosion proof dust collector must meet stringent criteria to ensure it can withstand potential explosive forces without compromising safety. This includes features like sealed construction, specialized filters designed for efficient dust separation, and robust grounding systems that help dissipate static electricity—a common ignition source in combustible environments. Understanding these safety standards is essential when selecting the right equipment for your operations.

How Explosion Proof Systems Work

Explosion proof systems function through a combination of design features aimed at preventing ignition sources from triggering an explosion within the system itself. The heart of an effective aluminum dust collector lies in its ability to contain any combustion event while minimizing pressure buildup that could lead to structural failure or release harmful materials into the environment.

These systems often incorporate advanced technologies such as pressure relief vents or explosion isolation valves that act as barriers against potential blasts while allowing safe operation under normal conditions. Additionally, utilizing high-efficiency filters within your dust collection system enhances overall performance by ensuring maximum capture of fine particles without compromising airflow or creating excessive vacuum pressure—key factors in maintaining a safe working environment.

In conclusion, investing in an explosion proof aluminum dust collector is not merely about compliance; it's about safeguarding lives and enhancing operational efficiency through effective risk management strategies tailored specifically for handling hazardous materials like aluminum dust.

Components of a Dust Collection System

In the realm of dust management, understanding the components of a dust collection system is crucial for ensuring safety and efficiency. Each part plays a significant role in effectively capturing and controlling harmful aluminum dust, which can pose serious risks in industrial settings. By integrating these essential elements, businesses can create a robust aluminum dust collector system that meets their specific needs.

Essential Parts of a Dust Collection System

A typical dust collection system consists of several key components: the dust collector itself, ductwork, filters, and exhaust systems. The dust collector is the heart of the operation, tasked with gathering airborne particles generated during various industrial processes. Ductwork serves as the network through which aluminum dust travels to reach the collector, while filters trap fine particles to ensure clean air is released back into the environment.

In addition to these primary elements, hoppers are often included to collect and store accumulated debris from the dust collection process. The efficiency of your entire system hinges on how well these parts work together; if one component falters, it can compromise overall performance. Therefore, investing in high-quality materials and technology is essential for any effective industrial dust collection solution.

The Role of Dust Separators

Dust separators are vital components within an aluminum dust collection system designed to enhance efficiency by pre-filtering larger particles before they reach the main dust collector unit. By removing heavier debris early on, separators help extend filter life and maintain optimal airflow throughout your system. This not only improves performance but also reduces maintenance costs associated with frequent filter replacements.

There are various types of separators available—cyclone separators being among the most popular for their ability to efficiently spin out larger particles using centrifugal force. Integrating a separator into your setup can significantly boost your overall dust separation capabilities while minimizing wear on your primary filtration systems. Ultimately, utilizing effective separators ensures that your aluminum dust collector operates at peak performance levels.

Importance of Dust Collector Vacuum Performance

The vacuum performance of a dust collection system is paramount when dealing with hazardous materials like aluminum dust; after all, it's not just about collecting dirt—it's about safety! A well-functioning vacuum ensures that airborne particles are effectively captured at their source before they have a chance to settle or disperse into the environment. This capability is crucial for maintaining air quality standards and protecting workers from harmful exposure.

Moreover, consistent vacuum performance contributes directly to energy efficiency within industrial operations; underperforming systems may require more power to achieve desired results, leading to increased operational costs over time. Regularly monitoring and maintaining vacuum performance will not only keep your equipment running smoothly but will also safeguard against potential explosions caused by accumulated combustible aluminum dust in poorly managed environments. Investing in high-quality vacuums tailored for specific applications will yield long-term benefits for both safety and cost-effectiveness in any industrial setting.

NAROO's Solutions for Dust Collection

When it comes to dust collection, NAROO stands out with innovative solutions designed specifically for the challenges posed by aluminum dust. With a commitment to safety and efficiency, NAROO's products elevate the standards of dust management in industrial settings. Their advanced technology ensures that businesses can maintain compliance while safeguarding their operations from the risks associated with aluminum dust.

Overview of NAROO's Innovations

NAROO has revolutionized the dust collection industry by integrating cutting-edge technology into their systems. Their approach combines robust engineering with intelligent design, resulting in dust collectors that not only capture aluminum particles effectively but also enhance overall workplace safety. By focusing on features such as enhanced filtration and superior airflow, NAROO’s innovations provide a comprehensive solution for any industrial dust collection system.

The company has invested heavily in research and development to create products that meet stringent safety standards while optimizing performance. This commitment is evident in their explosion-proof designs, which are tailored specifically for environments where aluminum dust poses significant hazards. By prioritizing both functionality and safety, NAROO ensures that every dust collector is equipped to handle the unique challenges of aluminum dust separation.

Specific Products for Aluminum Dust Collection

NAROO offers a range of specialized products designed explicitly for effective aluminum dust collection. Their flagship models include high-efficiency aluminum dust collectors that feature advanced filtration systems capable of capturing even the smallest particles. These systems are engineered to operate seamlessly within various industrial environments, ensuring maximum performance during critical operations.

In addition to standalone collectors, NAROO provides integrated solutions that can be incorporated into existing manufacturing setups. These products are designed with flexibility in mind, allowing businesses to customize their dust collection systems according to specific needs without compromising on efficiency or safety. The result is a comprehensive suite of tools tailored for optimal performance in managing aluminum dust.

Notably, NAROO’s vacuum units are also equipped with powerful suction capabilities specifically aimed at removing hazardous particles from workspaces quickly and efficiently. This combination of strong suction power and effective filtration makes them an essential component of any industrial dust collection strategy focused on handling aluminum materials.

Case Studies: NAROO in Action

To illustrate the effectiveness of NAROO’s solutions, consider several case studies showcasing successful implementations across various industries dealing with aluminum dust issues. In one instance, a major automotive manufacturer faced significant challenges due to excessive buildup of aluminum shavings during production processes. After integrating a customized NAROO aluminum dust collector into their system, they reported a remarkable reduction in airborne particles and improved overall air quality.

Another case involved an aerospace company struggling with compliance issues related to OSHA regulations regarding metal particulate exposure levels. By adopting NAROO’s advanced vacuum units paired with an efficient ducting system for optimal airflow management, they not only met regulatory requirements but also enhanced worker safety significantly—a win-win situation!

These examples highlight how investing in quality equipment like those offered by NAROO transforms workplaces plagued by hazardous conditions into safer environments conducive to productivity and compliance—proving once again why choosing the right collector is paramount when dealing with challenging materials like aluminum.

Choosing the Right Dust Collector for Your Needs

Selecting the right aluminum dust collector is crucial for ensuring safety and efficiency in your industrial operations. With a plethora of options available, understanding the specific needs of your dust collection system can make all the difference. From performance capabilities to compliance with safety standards, every factor plays a significant role in your decision-making process.

Factors to Consider in Selection

When choosing an aluminum dust collector, several factors should be top of mind. First and foremost, consider the volume of dust generated during operations; this will help determine the size and power of your dust collection system. Additionally, assess the type of processes involved—certain applications may require specialized features like enhanced filtration or explosion-proof designs to effectively manage hazardous aluminum dust.

Another important aspect is the layout and space available for installation. Compact designs can fit into tighter spaces while still maintaining high performance levels, which is essential in busy industrial environments.

Comparing Industrial Dust Collection Systems

In comparing industrial dust collection systems, it's vital to evaluate their efficiency and effectiveness in handling aluminum dust specifically. Look for systems that offer robust filtration capabilities while ensuring optimal air flow rates—this combination will maximize both performance and safety. Additionally, consider energy consumption; some models are designed to be more energy-efficient without compromising on power or effectiveness.

Another comparison point is the technology used within each system; advanced features like automatic cleaning mechanisms or real-time monitoring can enhance overall functionality significantly. These innovations not only improve operational efficiency but also prolong equipment life by preventing clogging and wear over time. Lastly, take note of manufacturer support; having access to reliable customer service can be invaluable when troubleshooting issues with your collector dust system.

Maintenance Tips for Optimal Performance

To keep your aluminum dust collector running at peak performance, regular maintenance is non-negotiable. Start with routine inspections; checking filters for clogs and ensuring that all components are functioning properly can prevent larger issues down the line. Additionally, creating a schedule for cleaning out collected debris from your dust separation units helps maintain airflow efficiency—a critical factor when dealing with fine aluminum particles.

Don’t forget about lubrication! Keeping moving parts well-lubricated reduces friction and wear on mechanical components within your collector dust system—this simple step can extend its lifespan considerably. Finally, always refer to manufacturer guidelines regarding maintenance schedules and procedures; following these recommendations ensures that you’re getting the most out of your investment in an effective aluminum dust management solution.

Conclusion

In summary, effective dust collection is not just a regulatory necessity but a vital component of workplace safety and operational efficiency. By implementing proper dust collection systems, businesses can significantly reduce the risks associated with aluminum dust, ensuring a safer environment for their employees and minimizing potential hazards. Enhanced safety measures not only protect workers but also contribute to overall productivity by maintaining cleaner workspaces.

Enhancing Safety with Proper Dust Collection

The implementation of an aluminum dust collector is crucial in enhancing safety in industrial settings where aluminum dust is prevalent. These collectors are specifically designed to capture and contain hazardous particles, preventing them from becoming airborne and causing explosions or health issues. By investing in reliable dust collection systems, companies can create a safer working environment that prioritizes employee well-being.

The Impact of Effective Dust Management

Effective management of aluminum dust through advanced dust collection techniques has far-reaching benefits beyond mere compliance with regulations. It leads to improved air quality within facilities, which can enhance worker morale and productivity while reducing sick days related to respiratory issues caused by airborne particulates. Furthermore, efficient dust separation processes ensure that machinery operates smoothly and reduces maintenance costs associated with excessive buildup.

Investing in Quality and Innovation with NAROO

Their commitment to quality ensures that each collector dust unit is designed to meet stringent safety standards while providing superior performance in capturing fine particles effectively. By opting for NAROO's advanced technologies, businesses not only invest in state-of-the-art equipment but also foster a culture of safety that pays dividends long-term.