Introduction

In the world of industrial air filtration, understanding the costs associated with a baghouse filter system is crucial for any business looking to maintain efficiency and compliance. These systems are essential for controlling dust emissions and ensuring clean air in various manufacturing processes. However, navigating the pricing landscape can be complex, influenced by factors such as filter media selection and technology advancements.

Understanding Baghouse Filter System Costs

The cost of a baghouse filter system encompasses more than just the initial purchase price; it includes installation, maintenance, and operational expenses that accumulate over time. Essential components like filtration bags play a significant role in determining these costs, as their quality directly impacts performance and longevity. By grasping these financial elements, businesses can make informed decisions that optimize their investment in dust filtration bags.

The Role of Filter Media in Pricing

Filter media is at the heart of any baghouse filter system, influencing both effectiveness and cost efficiency. The type of media selected—be it traditional or pleated filters—can drastically alter pricing structures due to variations in material composition and design benefits. Understanding how different filtration bags affect overall expenses helps companies align their air quality needs with budgetary constraints.

Why Pleated Filters Matter

Pleated filters have gained popularity due to their superior dust-holding capacity and extended service life compared to standard options. Their unique design allows for greater surface area without increasing footprint size, making them an excellent choice for facilities with limited space or high filtration demands. Investing in pleated filters not only enhances performance but also contributes to long-term savings on replacement costs within a baghouse filter system.

Key Components of a Baghouse Filter System

Each part plays a significant role in the overall functionality and efficiency of industrial air filtration systems. From filtration bags to advanced technology, these elements not only dictate performance but also influence pricing.

Essential Parts That Drive Costs

The essential parts of a baghouse filter system include the housing, fan, ductwork, and most importantly, the filtration bags themselves. Each component contributes to both initial setup costs and long-term operational expenses. For instance, high-quality dust filtration bags can significantly raise upfront costs but lead to lower maintenance and replacement needs over time.

Importance of Filtration Bags

Filtration bags are the heart of any baghouse filter system; they determine how effectively dust and other particulates are captured from the air stream. The choice between traditional filters and pleated filters can make or break your budget—pleated filters tend to have a higher upfront cost but offer increased surface area for better dust capture efficiency. In an industrial setting where air quality is paramount, investing in superior filtration bags pays off through reduced downtime and enhanced operational efficiency.

How Technology Influences Prices

Technology has become a game-changer in the realm of baghouse filters, driving both innovation and costs up or down depending on various factors. Advanced features such as automated cleaning systems or smart monitoring can add significant value but come with an increased price tag. However, these technologies often lead to lower energy consumption and decreased labor costs over time, making them worthwhile investments in your industrial air filtration strategy.

Types of Filter Media and Their Impact

Different filtration bags serve diverse applications, each tailored to specific industrial air filtration needs. Understanding these variations helps businesses make informed decisions that balance effectiveness with budget constraints.

Comparing Different Filtration Bags

Filtration bags come in various materials and designs, each with its unique properties that affect their efficiency in a baghouse filter system. For instance, traditional felt bags are often less expensive but may not capture fine dust particles as effectively as their synthetic counterparts. On the other hand, advanced options like pleated filters offer higher surface area and enhanced dust retention capabilities, making them an attractive choice for industries requiring robust dust filtration.

In comparing these options, it's essential to consider how factors like airflow resistance and longevity impact overall costs. While cheaper filtration bags might seem appealing initially, they could lead to increased maintenance expenses or more frequent replacements down the line. Ultimately, investing in high-quality filtration bags can save money over time by reducing downtime and improving operational efficiency.

Advantages of Pleated Filters

Pleated filters have emerged as a game-changer in the world of industrial air filtration due to their superior design and performance characteristics. The pleating increases the surface area available for capturing particulates while maintaining low airflow resistance—a crucial factor for efficient operation in a baghouse filter system. This means that pleated filters can often last longer than traditional flat filters while providing better dust collection.

Moreover, pleated filters are versatile enough to handle various types of contaminants across multiple industries, from manufacturing to food processing. Their ability to trap finer particles without sacrificing airflow makes them particularly valuable for facilities aiming for compliance with strict environmental regulations. Therefore, choosing pleated filters can enhance both air quality and operational effectiveness while potentially lowering long-term costs associated with replacement filters.

Cost Factors for Specialized Media

Specialized filter media is designed for specific applications within a baghouse filter system but often comes at a premium price point compared to standard options. Factors such as material composition, manufacturing processes, and intended use all contribute to the cost of these advanced filtration bags or bag dust filters. For instance, media engineered for high-temperature environments or those resistant to chemical exposure will typically command higher prices due to their specialized nature.

However, it’s important not just to look at upfront costs when considering specialized media; evaluating total ownership costs—including maintenance requirements and replacement frequency—can provide a clearer picture of value over time. While investing in high-end filtration solutions may seem daunting initially, they often lead to improved performance metrics that justify the investment by reducing operational disruptions caused by inadequate air quality management systems. Thus, businesses should weigh their specific needs against potential long-term savings when selecting filter media.

Maintenance and Operational Costs

These costs can significantly impact your budget, especially when considering the type of filter media you choose. A well-maintained filtration system not only performs better but also extends the life of essential components like pleated filters and dust filtration bags.

Long-Term Budgeting for Filtration Systems

Long-term budgeting for a baghouse filter system involves more than just the initial purchase price; it requires careful planning for ongoing expenses. The cost of quality filter media, such as pleated filters, can fluctuate based on market conditions and technological advancements. By forecasting these costs, businesses can allocate resources effectively and avoid unexpected financial strain in their industrial air filtration systems.

The Cost of Replacement Filters

Replacement filters are a significant part of the operational costs associated with a baghouse filter system. Depending on the type of filtration bags used—whether standard or specialized—the expense can vary widely. Investing in high-quality dust filtration bags may seem pricier upfront but often leads to lower replacement frequency and better overall performance.

Importance of Regular Maintenance

Regular maintenance is vital to ensure that your baghouse filter operates at peak efficiency. Neglecting routine checks can lead to premature wear on pleated filters and other critical components, resulting in higher long-term costs. By committing to a proactive maintenance schedule, businesses can enhance their industrial air filtration systems' reliability while minimizing costly downtime.

Industry-Specific Considerations

When it comes to industrial air filtration, different sectors have unique requirements that significantly affect the choice and cost of a baghouse filter system. Heavy industries like mining, cement manufacturing, and metalworking generate high volumes of dust and particulate matter, necessitating robust filtration solutions. In these environments, the type of filter media used—whether traditional filtration bags or advanced pleated filters—can make a substantial difference in performance and operational efficiency.

Unique Requirements in Heavy Industries

Heavy industries often deal with abrasive dust particles that can quickly wear down standard filtration bags. This means that investing in durable bag dust filters designed specifically for tough conditions is essential for maintaining optimal air quality and equipment longevity. Additionally, these sectors may require custom configurations of their baghouse filter systems to accommodate varying airflow rates and specific contaminants present in their processes.

Variability in Air Filtration Needs

Air filtration needs can vary widely even within the same industry due to factors such as production methods, types of materials processed, and regulatory compliance measures. For instance, a facility dealing with fine powders may need specialized dust filtration bags that provide higher efficiency than standard options. Consequently, businesses must evaluate their specific requirements carefully to select the right baghouse filter system that balances cost with effective performance.

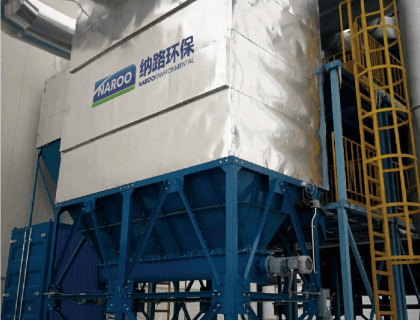

Custom Solutions from NAROO

NAROO stands out by offering tailored solutions for diverse industrial air filtration challenges through innovative designs and advanced filter media technologies. With options like pleated filters that maximize surface area while minimizing resistance, companies can enhance their dust collection efficiency without incurring excessive costs on maintenance or replacements. By collaborating with NAROO to develop custom baghouse filter systems, industries can ensure they meet both operational demands and budget constraints effectively.

Innovations Affecting Costs

In the ever-evolving landscape of industrial air filtration, innovations play a pivotal role in determining the costs associated with baghouse filter systems. From advanced filter media to cutting-edge automation technologies, these developments can significantly affect both initial investments and long-term operational expenses. Understanding these innovations helps businesses make informed decisions that enhance efficiency and reduce costs.

Advancements in Baghouse Filter Technology

Recent advancements in baghouse filter technology have revolutionized how dust filtration bags operate, enhancing their efficiency and lifespan. New materials and designs for pleated filters allow for greater surface area without increasing size, improving airflow while reducing pressure drop. As a result, businesses can enjoy lower energy costs while maintaining effective filtration performance—an essential factor for any baghouse filter system.

Moreover, manufacturers are now integrating smart sensors into their bag dust filters to monitor performance in real-time. These sensors can provide valuable data on filter condition and air quality, enabling proactive maintenance and reducing the risk of costly downtime. With such technological strides, investing in modern filtration bags becomes more appealing as they deliver both immediate savings and long-term benefits.

The Role of Automation in Cost Management

Automation is transforming cost management within the realm of industrial air filtration systems by streamlining operations and minimizing human error. Automated cleaning systems for baghouse filters ensure optimal performance by regularly removing accumulated dust from the filtration bags without manual intervention. This not only extends the life of the filters but also reduces labor costs associated with maintenance.

Furthermore, automated monitoring systems provide insights into operational efficiency that were previously unattainable. By analyzing data trends related to airflow, pressure drops, and filter saturation levels, companies can optimize their use of pleated filters to achieve peak performance at lower costs. As a result, businesses equipped with automated solutions often see a significant reduction in overall expenditure related to their baghouse filter system.

Sustainability and Its Influence on Pricing

Sustainability is increasingly influencing pricing strategies across industries, particularly concerning air filtration solutions like baghouse filter systems. Companies are recognizing that eco-friendly practices not only enhance their brand image but also lead to cost savings over time through reduced energy consumption and waste generation from disposable dust filtration bags. Consequently, many manufacturers are developing sustainable materials for pleated filters that offer high performance while minimizing environmental impact.

Moreover, regulations aimed at promoting sustainability are prompting organizations to invest in advanced filtering technologies that comply with stricter emissions standards. While this may initially seem like an added expense, the long-term benefits—such as reduced fines or penalties—can offset these upfront costs significantly. Thus, embracing sustainability isn’t just good for the planet; it’s also economically savvy when considering the total cost of ownership for industrial air filtration systems.

Conclusion

In wrapping up our exploration of the baghouse filter system, it’s essential to revisit the key cost factors that influence both initial investment and ongoing expenses. Understanding the role of filter media, particularly pleated filters and filtration bags, is crucial for making informed decisions. Additionally, recognizing how technology impacts pricing can help businesses optimize their industrial air filtration strategies.

Recap of Key Cost Factors

When considering a baghouse filter system, several cost factors come into play. The type of filter media selected—whether traditional dust filtration bags or advanced pleated filters—can significantly affect both upfront costs and long-term performance. Moreover, maintenance requirements and replacement frequency are vital in calculating overall expenses associated with a bag dust filter.

Insights into Future Trends

Looking ahead, innovations in baghouse filter technology promise to reshape the landscape of industrial air filtration. Advances such as automation will likely streamline operations and reduce costs while enhancing efficiency. Additionally, sustainability initiatives are becoming more influential; as businesses strive for greener solutions, the demand for high-performance filtration systems will continue to grow.

Choosing the Right Systems for Efficiency

Selecting the right baghouse filter system requires careful consideration of both cost and performance metrics. Prioritizing high-quality filtration bags—especially pleated filters—can lead to improved efficiency and lower operational costs over time. By evaluating specific needs and future trends in industrial air filtration, companies can invest wisely in systems that deliver optimal results.