Introduction

When it comes to maintaining a clean and efficient workspace, understanding the intricacies of a cyclone vacuum dust collector is essential. These powerful devices are designed to enhance your shop vac dust collection system by efficiently removing sawdust and debris from the air. Whether you're a hobbyist or a professional woodworker, having a reliable dust collection system for your wood shop can significantly improve both safety and productivity.

Understanding Cyclone Vacuum Dust Collectors

Cyclone vacuum dust collectors utilize centrifugal force to separate dust and debris from the air, making them an effective solution for any shop dust collection system. By integrating a cyclone separator with your existing shop vac, you can greatly enhance its performance while prolonging its lifespan. This innovative technology allows for more efficient airflow, ensuring that your workspace remains clear of harmful particles.

The Importance of a Dust-Free Workspace

A dust-free workspace is not just about aesthetics; it's crucial for health and safety. Fine wood particles can lead to respiratory issues if inhaled over time, making it vital to implement an effective dust collection system with shop vac capabilities. Moreover, maintaining cleanliness in your workshop helps prevent accidents and ensures that your tools operate efficiently without the interference of debris.

Budgeting for a Shop Dust Collection System

Creating an effective shop dust collection system doesn't have to break the bank; budgeting wisely can lead you to affordable solutions without sacrificing quality. By exploring DIY options or sourcing materials strategically, you can build a cyclone vacuum dust collector tailored to your needs without overspending. With careful planning and consideration, achieving an efficient shop vac dust collection setup is entirely feasible on any budget.

What is a Cyclone Vacuum Dust Collector?

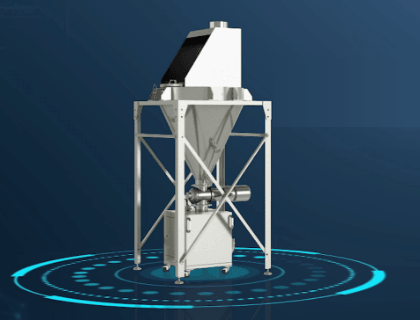

Cyclone vacuum dust collectors are ingenious devices designed to efficiently separate dust and debris from the air in your workshop. By utilizing centrifugal force, these systems create a cyclone effect that allows for effective collection of wood shavings, sawdust, and other particles. Whether you're a hobbyist or a professional, understanding how these systems work can significantly enhance your shop vac dust collection system.

Overview of Cyclone Technology

At the heart of cyclone vacuum dust collectors lies the principle of cyclonic separation. This technology harnesses the power of spinning air to fling heavier particles towards the container's walls, allowing cleaner air to exit through the top. By incorporating this design into your dust collection system for wood shop applications, you can achieve superior filtration and reduce wear on your shop vac.

The beauty of cyclone technology is its simplicity and effectiveness; it requires no filters that need constant changing or cleaning, making maintenance a breeze. As you explore options for a shop dust collection system, consider how this innovative approach can streamline your woodworking processes while keeping your workspace tidy. With a well-designed cyclone vacuum dust collector, you’ll be able to tackle even the biggest messes with ease.

How It Works in a Wood Shop

In practice, using a cyclone vacuum dust collector in your wood shop involves connecting it to your existing shop vac dust collection setup. When you turn on the system, air laden with sawdust and debris enters the cyclone chamber at high speed. The swirling motion causes heavier particles to be thrown against the walls and drop into a collection bin below while cleaner air spirals upwards toward the filter or exhaust.

This efficient separation means that less material reaches your shop vac itself—extending its life and improving suction power over time. Moreover, since most systems are compatible with standard hoses and fittings found in many workshops today, integrating one into your existing setup is usually straightforward. Ultimately, investing in a quality dust collection system with shop vac compatibility can transform how you manage waste during projects.

Benefits for Hobbyists and Professionals

For hobbyists seeking an organized workspace or professionals aiming for efficiency, there are numerous advantages to utilizing a shop vacuum dust collector equipped with cyclone technology. First off, it drastically reduces airborne particulates that could otherwise lead to respiratory issues over time—keeping both you and your workspace healthier!

Additionally, by minimizing clogs in filters associated with traditional systems—thanks to effective particle separation—you'll find yourself spending less time on maintenance tasks like changing bags or cleaning filters frequently. Lastly, whether you're crafting intricate furniture pieces or tackling large-scale projects in commercial settings, having an efficient dust collection system ensures optimal performance without compromising cleanliness.

Key Components of a Budget-Friendly System

Creating a budget-friendly cyclone vacuum dust collector system requires careful consideration of essential components, sourcing affordable materials, and deciding between DIY and pre-made solutions. This section will guide you through the critical parts necessary for an effective shop vac dust collection system while keeping costs in check. By understanding these elements, you can ensure your dust collection system for wood shop is both efficient and economical.

Essential Parts for a Shop Vac Dust Collection

To build an effective shop dust collection system, you'll need several key components that work harmoniously together. First and foremost is the cyclone separator itself, which efficiently captures larger particles before they reach your vacuum. Other essential parts include ducting to connect various tools to the cyclone, a sturdy mounting bracket for stability, and a filter to ensure fine dust doesn't escape back into your workshop.

Don't forget about the power source; your shop vac should have enough suction power to handle the demands of your dust collection system with shop vac attachments. Additionally, consider investing in blast gates that allow you to control airflow between different tools easily—this can significantly enhance efficiency in your setup. With these essential parts assembled thoughtfully, you'll have a robust shop vac dust collection that keeps your workspace clean and safe.

Sourcing Affordable Materials

Finding affordable materials for your cyclone vacuum dust collector doesn’t have to be a daunting task; it just requires some creativity and resourcefulness! Start by checking out local hardware stores or home improvement centers where you can often find budget-friendly options for ducting and connectors. Online marketplaces like Craigslist or Facebook Marketplace may also offer second-hand equipment—just make sure it’s in good condition before purchasing!

Recycling materials can also be an excellent way to save money while being environmentally friendly; old buckets or barrels can serve as excellent containers for collecting debris from your shop dust collector. If you're feeling adventurous, consider exploring DIY plans available online that provide lists of materials needed along with instructions on how to construct each component effectively without breaking the bank. With diligence in sourcing affordable materials, you’ll create a cost-effective yet powerful dust collection system.

DIY vs. Pre-Made Solutions

When deciding whether to pursue DIY or pre-made solutions for your shop vac dust collection needs, it's essential to weigh the pros and cons of each approach carefully. A DIY cyclone vacuum dust collector allows you complete control over design choices while often being more cost-effective than purchasing pre-made systems—plus it’s incredibly satisfying to see something you've built perform well! However, this route does require time investment and some level of technical skill.

On the other hand, opting for pre-made solutions might save time but could come at a higher price point without guaranteeing customization tailored specifically to your workshop's needs. Many manufacturers now offer reasonably priced options designed specifically for compatibility with existing setups like a shop vac dust collection system—these are great if you're short on time or expertise but still want quality performance from your equipment! Ultimately, whether you go DIY or choose pre-made solutions will depend on how much time you're willing to invest versus how much customization you desire in achieving an efficient shop dust collector.

Step-by-Step Guide to Building Your Collector

Creating your own cyclone vacuum dust collector can be a rewarding project that enhances your shop's efficiency. By following this step-by-step guide, you’ll not only save money but also gain a deeper understanding of how a dust collection system for wood shops operates. Let’s get started on building your very own shop dust collection system!

Planning Your Dust Collection System

Before diving into construction, it’s crucial to plan out your dust collection system with precision. Start by assessing the layout of your workshop and identifying the tools that generate the most sawdust and debris; this will help you determine the ideal placement for your cyclone vacuum dust collector. Consider factors like airflow, ducting length, and how many machines you want to connect to your shop vac dust collection system.

Next, sketch a diagram that outlines where each component will go. This includes the cyclone separator, shop vac, and any ductwork necessary for effective extraction of dust from all areas of your workspace. Remember, a well-planned setup not only maximizes efficiency but also ensures that your shop vac dust collection runs smoothly without unnecessary blockages or loss of suction.

Assembly Instructions for Your Cyclone Vacuum

Once you've mapped out your design, it's time to gather materials and start assembling your cyclone vacuum dust collector! Begin with constructing the cyclone separator; this typically involves connecting a conical-shaped container to a sturdy base that fits snugly over or around your shop vac. Make sure all joints are sealed tightly to prevent any air leaks which could compromise suction power in the overall shop dust collection system.

After setting up the cyclone unit, connect it to your vacuum using appropriate hoses or ducting materials designed for high airflow and minimal resistance. Ensure that all connections are secure; loose fittings can lead to reduced performance in both suction power and filtration effectiveness in capturing fine particles from the air in your workshop environment. Finally, integrate any additional features like blast gates or filters as needed based on how complex you want your setup.

Testing and Adjusting Performance

With everything assembled, it’s time for some testing! Turn on your newly built cyclone vacuum dust collector while running one of the tools connected to it—watch closely as sawdust is sucked away into the separator rather than dispersing into the air around you. If you notice any inefficiencies during this process—like poor suction or excessive noise—it may require adjustments such as repositioning hoses or adding additional support structures.

Fine-tuning is an essential part of optimizing performance within any shop vac dust collection system; don't hesitate to experiment with different configurations until you find what works best for both airflow and noise levels in relation to how much debris is generated by each tool used in conjunction with the vacuum dust collector setup you've created. Regular maintenance checks will help ensure longevity and efficiency going forward!

Maximizing Efficiency in Your Dust Collection

When it comes to your dust collection system for a wood shop, efficiency is key. A well-placed cyclone vacuum dust collector can make all the difference in maintaining a clean workspace and ensuring optimal performance. Let’s dive into how you can maximize the effectiveness of your shop vac dust collection system.

Proper Placement Within Your Workshop

The placement of your cyclone vacuum dust collector is crucial for achieving maximum efficiency. Ideally, it should be located near the primary sources of dust and debris, such as your table saw or sander, to minimize the distance that particles must travel. Additionally, consider positioning it away from walls and corners to allow for better airflow and easier access when it's time to empty the collection bag.

Incorporating flexible ducting can help direct the flow from various machines to your shop vac dust collection system without creating unnecessary bends or kinks that could hinder performance. You want to ensure that every tool in your workshop is connected effectively, creating a seamless operation for your shop dust collection system. With thoughtful placement, you’ll notice a significant reduction in airborne particles and an overall cleaner environment.

Connecting to Your Shop Vac Dust Collection

Integrating your cyclone vacuum with a shop vac dust collection setup can be straightforward if done correctly. Start by ensuring that all connections are airtight; leaks can drastically reduce suction power and overall efficiency of your dust collection system with shop vacs. Use high-quality duct tape or clamps on all joints to maintain optimal airflow and prevent any pesky debris from escaping.

Next, consider using a blast gate at each connection point; this allows you to control which tools are actively connected to the cyclone vacuum dust collector at any given time. By shutting off unused lines, you enhance suction power where it's needed most—directly at the source of the mess! This tailored approach not only improves performance but also prolongs the life of both your vacuum and cyclone unit.

Maintenance Tips for Longevity

Maintaining your cyclone vacuum dust collector is essential for ensuring its longevity and peak performance over time. Regularly check filters and bags; clogged components can significantly reduce suction efficiency in any shop dust collector setup. Clean or replace these parts as needed—most manufacturers provide guidelines on how often this should be done based on usage frequency.

Additionally, inspect hoses and connections for wear or damage periodically; even small cracks can lead to major losses in suction power within your shop vac dust collection system. Keeping everything clean will not only extend the life of your equipment but also ensure that you're breathing cleaner air while working on projects in your workshop! Remember: a little maintenance goes a long way toward keeping that cyclone vacuum running smoothly.

Real-World Applications of Cyclone Systems

Cyclone vacuum dust collectors are becoming increasingly popular among woodworkers and hobbyists alike, thanks to their efficiency and versatility. Whether you’re a weekend warrior or a professional craftsman, a well-designed shop dust collection system can transform your workspace into a cleaner and safer environment. Let’s dive into some real-world applications that showcase the effectiveness of these systems.

Case Studies from NAROO Users

Users of NAROO’s cyclone vacuum dust collector have reported significant improvements in their workshop environments. For instance, one user transformed his cluttered garage into a functional wood shop by implementing a DIY dust collection system with shop vac components, resulting in less time spent on cleanup and more time for creativity. Another case study highlighted how an artist incorporated a compact shop vac dust collection system to manage fine particulate matter while crafting intricate wood designs, showcasing the adaptability of these systems across various projects.

Adaptations for Different Workshop Sizes

One of the remarkable features of cyclone vacuum dust collectors is their adaptability to different workshop sizes. Small workshops can benefit from compact systems that integrate seamlessly with existing equipment, ensuring effective debris management without taking up too much space. Conversely, larger commercial spaces might require more robust setups with multiple connections to various machines, maximizing the efficiency of their shop vac dust collection system while keeping the workspace clean and organized.

Benefits for Various Industries

The versatility of cyclone vacuum dust collectors extends beyond woodworking; they are invaluable in numerous industries such as metalworking, automotive repair, and even food processing. In metalworking shops, for example, these systems efficiently capture metal shavings and particles that could pose safety hazards if left unchecked. Similarly, in food processing facilities where cleanliness is paramount, a reliable dust collection system helps maintain hygiene standards while minimizing downtime caused by cleanup efforts—demonstrating that investing in an effective shop dust collector pays off across diverse applications.

Conclusion

In wrapping up our exploration of the cyclone vacuum dust collector, it’s clear that achieving a cleaner workspace doesn't have to break the bank. A well-planned shop dust collection system can significantly improve both safety and efficiency in your wood shop. By leveraging affordable materials and DIY strategies, you can create a robust dust collection system with a shop vac that meets your needs without emptying your wallet.

Achieving a Cleaner Workspace on a Budget

Creating an effective dust collection system for your wood shop doesn’t require an extravagant budget or high-end equipment. With a little creativity and resourcefulness, you can build a functional shop dust collector that works seamlessly with your existing tools. Investing in a cyclone vacuum dust collector not only enhances air quality but also protects your equipment from harmful debris, ensuring longevity for both your health and tools.

The Impact of Effective Dust Collection

The benefits of implementing an efficient shop vac dust collection system extend far beyond mere aesthetics; they touch on health, safety, and productivity as well. A well-designed dust collection system with shop vac capabilities minimizes airborne particles, reducing respiratory risks while you work in your workshop. Furthermore, maintaining a clean environment fosters better focus and efficiency—essential elements for hobbyists and professionals alike who are serious about their craft.

Your Next Steps to Build a Cyclone Vacuum Dust Collector

Now that you're equipped with knowledge about the components needed for an effective vacuum dust collector, it’s time to roll up those sleeves! Start by sketching out your ideal setup based on the space available in your workshop; remember that proper placement is key to maximizing efficiency. Gather materials based on our sourcing tips, assemble your cyclone vacuum dust collector step-by-step, test its performance, and enjoy the satisfaction of working in a cleaner environment.