Introduction

In the industrial world, metal dust from grinding is more than just a nuisance; it poses serious health risks to workers and can compromise equipment efficiency. As metal components are ground down, fine particles are released into the air, creating a hazardous environment that requires immediate attention. Understanding these risks is crucial for maintaining a safe workplace and ensuring compliance with industry standards.

Understanding the Risks of Metal Dust

Metal dust from grinding can lead to respiratory issues, skin irritation, and even long-term health complications if not properly managed. Workers exposed to high levels of this dust may experience symptoms ranging from coughing to chronic lung diseases, making effective control measures essential. Additionally, metal dust can ignite under certain conditions, posing fire hazards that further elevate workplace dangers.

Importance of Effective Extraction Solutions

Effective extraction solutions are vital in mitigating the risks associated with metal dust from grinding. Grinding dust collectors play a crucial role in capturing airborne particles before they settle or become inhaled by workers. By investing in reliable cutting and grinding dust extraction systems, companies not only protect their employees but also enhance productivity by keeping workspaces cleaner and safer.

Exploring NAROO's Role in Dust Management

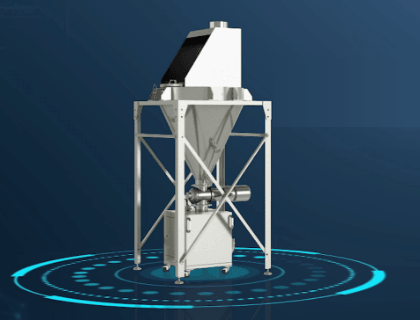

NAROO has emerged as a key player in the realm of dust management solutions, providing innovative technologies designed to tackle the challenges presented by metal dust from grinding. With an emphasis on quality and efficiency, NAROO offers advanced grinding dust collectors that integrate seamlessly into existing operations. Their commitment to creating safer environments reflects a broader industry trend towards prioritizing worker health while optimizing operational performance.

The Science Behind Metal Dust from Grinding

Understanding the origins and implications of metal dust from grinding is crucial for maintaining a safe workplace. This section delves into what causes this dust, its health effects, and the standards set to control it. By grasping these concepts, businesses can implement effective strategies for managing grinding dust collectors and cutting and grinding dust extraction.

What Causes Metal Dust in Grinding

Metal dust from grinding is primarily generated when abrasive materials interact with metal surfaces during the machining process. The friction created by the grinding wheel or disc leads to tiny particles being dislodged, which then become airborne as fine dust. Factors such as the type of material being ground, the speed of operation, and even environmental conditions can significantly influence the volume of metal dust produced.

In essence, every time you engage in a grinding operation, you risk creating a cloud of fine particles that can linger in the air long after work has ceased. This makes understanding the mechanics behind metal dust generation vital for implementing effective cutting and grinding dust extraction measures. By recognizing these causes, businesses can better tailor their approaches to minimize exposure and enhance workplace safety.

Effects of Metal Dust on Health

The health implications associated with inhaling metal dust from grinding are far-reaching and potentially severe. Prolonged exposure can lead to respiratory issues such as asthma or chronic bronchitis, while certain metals may even contribute to more serious conditions like lung cancer or neurological disorders over time. The microscopic size of these particles allows them to penetrate deep into lung tissue, exacerbating their harmful effects.

Moreover, workers may experience symptoms ranging from irritation of the eyes and throat to more debilitating respiratory illnesses if protective measures are not taken seriously. Understanding these risks emphasizes why investing in quality grinding dust collectors is not just an operational choice but a moral imperative for employers committed to worker safety. Awareness around these health risks fosters a culture where safety practices are prioritized over convenience.

Industry Standards for Dust Control

To combat the hazards posed by metal dust from grinding effectively, various industry standards have been established to guide organizations in implementing proper controls. Regulatory bodies such as OSHA (Occupational Safety and Health Administration) provide guidelines that dictate permissible exposure limits (PELs) for different types of metal particulate matter found in workplaces. These standards serve as benchmarks against which companies can measure their compliance and effectiveness in managing airborne contaminants.

Additionally, best practices recommend using advanced technology like specialized grinding dust collectors designed specifically for capturing fine particles at their source—before they disperse into the air we breathe! Regular audits and adherence to industry regulations ensure that workplaces remain compliant while fostering an environment where employee health is prioritized through cutting-edge extraction techniques. By aligning with these standards, companies not only safeguard their workforce but also enhance productivity through improved air quality.

Innovative Grinding Dust Collectors

These devices not only capture harmful particles but also contribute to a cleaner and safer working environment. With various types of collectors available, it's crucial to understand which ones best suit your needs.

Types of Grinding Dust Collectors

There are several types of grinding dust collectors designed specifically for handling metal dust from grinding processes. The most common include baghouse collectors, cartridge-style units, and cyclonic separators. Each type has its own unique mechanism for capturing and filtering out the fine particles generated during cutting and grinding operations.

Baghouse collectors use fabric filters to trap dust particles, making them ideal for high-volume applications. Cartridge-style units offer a more compact design with high filtration efficiency, perfect for smaller workspaces where space is at a premium. Cyclonic separators utilize centrifugal force to remove larger debris before it reaches the filter, optimizing the overall performance of your dust collection system.

Key Features to Look For

When selecting a grinding dust collector, there are several key features you should prioritize to ensure effective performance against metal dust from grinding. First and foremost is the filtration efficiency; look for units that can capture particles as small as 0.3 microns or less. Additionally, consider the airflow capacity—higher airflow rates can enhance collection efficiency by minimizing the chances of re-entrainment.

Another important feature is ease of maintenance; models that allow quick access to filters or have self-cleaning capabilities can save time and reduce downtime in your operations. Noise levels should also be considered; quieter machines create a more pleasant working environment while still effectively managing cutting and grinding dust extraction needs.

Leading Brands in Dust Collection Technology

Several brands stand out in the realm of innovative grinding dust collectors, each offering unique products tailored to various industrial needs. Companies like Donaldson Torit and Festool are renowned for their advanced filtration technologies that effectively manage metal dust from grinding while ensuring compliance with industry standards.

Other notable brands include Grizzly Industrial and Baileigh Industrial, both known for their robust designs that cater specifically to heavy-duty applications in workshops and manufacturing environments. Investing in reliable equipment from these leading brands ensures not only superior performance but also long-term durability against wear and tear caused by constant exposure to abrasive materials.

Cutting and Grinding Dust Extraction Techniques

In the realm of cutting and grinding, effective dust extraction techniques are essential for maintaining a safe and productive work environment. Metal dust from grinding not only poses health risks but can also lead to equipment damage and reduced efficiency. By implementing best practices in dust extraction, industries can mitigate these hazards while enhancing overall operational performance.

Best Practices for Dust Extraction

When it comes to managing metal dust from grinding, adopting best practices is crucial for optimal results. One effective approach is to use high-efficiency Grinding dust collectors that are specifically designed for capturing fine particles generated during the grinding process. Additionally, positioning these collectors close to the source of dust generation ensures maximum capture efficiency and minimizes airborne particles in the workplace.

Regularly checking and maintaining your Cutting and Grinding Dust Extraction systems is another vital practice. This includes ensuring that filters are clean, ducts are free from blockages, and that all components are functioning correctly. By adhering to these practices, businesses not only comply with industry standards but also foster a healthier work environment for their employees.

Integrating Extractors into Existing Systems

Integrating modern extractors into existing systems can significantly enhance the efficiency of metal dust management strategies. Many facilities already have some form of dust collection; however, upgrading to advanced Grinding dust collectors can provide better filtration technology and improved airflow dynamics. This integration often involves assessing current operations to identify areas where new extraction solutions can be effectively implemented without disrupting productivity.

Moreover, it's essential to ensure compatibility between new extractors and existing machinery or workflows. Collaborating with manufacturers like NAROO can help tailor solutions that fit seamlessly within your operational framework while maximizing cutting and grinding dust extraction capabilities. This strategic integration not only improves air quality but also boosts overall workplace safety.

Benefits of Preventative Maintenance

Preventative maintenance is often an overlooked aspect when discussing metal dust from grinding management; however, it plays a pivotal role in ensuring long-term effectiveness of any extraction system. Regular maintenance helps identify potential issues before they become significant problems, thus reducing downtime caused by equipment failures or inefficiencies in capturing metal dust from grinding operations.

Additionally, well-maintained Grinding dust collectors operate more efficiently, leading to lower energy costs over time while providing better air quality control within the facility. Investing in preventative maintenance ultimately translates into higher productivity levels as employees work in a safer environment free from excessive exposure to harmful particles generated during cutting and grinding processes.

In conclusion, effective cutting and grinding dust extraction techniques encompass best practices tailored specifically for managing metal dust from grinding activities while integrating advanced technologies into existing systems through regular preventative maintenance checks.

Workplace Layout and Design Strategies

Creating an effective workplace layout is crucial for managing metal dust from grinding. The design of a workspace can significantly influence how dust is generated and controlled, impacting both employee safety and operational efficiency. By strategically placing equipment and incorporating appropriate extraction solutions, businesses can minimize the risks associated with grinding dust.

How Layout Impacts Dust Control

The layout of a workshop or manufacturing facility plays a pivotal role in controlling metal dust from grinding processes. An open space can allow for better airflow, which aids in the dispersal of particles; however, it may also lead to increased accumulation if not managed properly. By positioning cutting and grinding machines near effective grinding dust collectors, facilities can ensure that any airborne particles are swiftly captured before they settle on surfaces or enter the breathing zone.

Furthermore, organizing workstations to facilitate efficient movement can help reduce the likelihood of metal dust buildup. For instance, ensuring that workers have easy access to cleaning tools and extraction systems encourages regular maintenance routines that keep areas clean. Ultimately, a well-thought-out layout not only enhances productivity but also promotes a healthier work environment by reducing exposure to harmful metal dust.

Creating Effective Workstations

Effective workstations are essential for minimizing the generation of metal dust from grinding activities. A workstation designed with ergonomics in mind will allow operators to perform their tasks comfortably while maintaining focus on safety protocols related to dust management. Incorporating cutting and grinding dust extraction systems directly into these workstations ensures that any debris produced during operations is immediately addressed.

Moreover, equipping workstations with adequate storage for tools and materials reduces clutter, which can contribute to the accumulation of metal dust over time. Regularly scheduled clean-ups should be integrated into daily operations so that employees are encouraged to maintain their spaces diligently. With proper design elements such as these in place, companies can create an environment where productivity thrives alongside effective control of harmful particles.

Importance of Ventilation Systems

A robust ventilation system is one of the cornerstones of controlling metal dust from grinding operations effectively. Proper ventilation helps dilute airborne contaminants while directing them towards extraction points where cutting and grinding dust collectors can capture them efficiently. Without adequate ventilation, even the best-designed workplaces may struggle with excessive build-up of hazardous materials in the air.

Additionally, incorporating localized exhaust systems at points where most metal dust is generated—like grinders or saws—can significantly improve air quality within the facility. These systems should be regularly maintained to ensure optimal performance; otherwise, they may become less effective over time as filters clog or ducts become obstructed with accumulated debris. Investing in high-quality ventilation solutions not only protects employees’ health but also complies with industry standards regarding workplace safety.

Training and Awareness Programs

In the world of metalworking, knowledge is power—especially when it comes to understanding the risks associated with metal dust from grinding. Training programs should be designed to educate staff on how this fine particulate can impact their health and safety. By fostering a culture of awareness, organizations can significantly reduce the hazards posed by metal dust.

Educating Staff on Dust Risks

First and foremost, employees need to grasp the dangers inherent in working with metal dust from grinding. This includes understanding how prolonged exposure can lead to respiratory issues or other health complications. Regular workshops and informational sessions can help instill a sense of urgency regarding these risks, making safety a top priority for everyone involved.

Additionally, using engaging materials—like videos and interactive presentations—can make learning about dust risks more compelling. It’s crucial that workers recognize not just what they are dealing with but also why proper precautions are necessary when using grinding dust collectors or cutting and grinding dust extraction systems. Ultimately, well-informed employees are empowered employees who contribute to a safer workplace.

Implementing Safe Grinding Practices

Once staff members are educated on the risks associated with metal dust from grinding, it's time to implement safe practices that mitigate those risks effectively. This could involve developing standard operating procedures (SOPs) that outline how to use equipment safely while minimizing exposure to harmful dust particles. Incorporating regular training refreshers ensures that safe practices remain top-of-mind for all employees.

Moreover, integrating best practices into daily routines allows for seamless adoption of safety measures like proper use of grinding dust collectors and effective cutting and grinding dust extraction techniques. For instance, demonstrating how to correctly position extractors during operations can drastically reduce airborne particles in work areas. The goal is not just compliance but cultivating an environment where safety becomes second nature.

Encouraging Employee Involvement in Safety

A proactive approach involves encouraging employees to take ownership of their safety as well as their colleagues'. Creating feedback loops where workers can voice concerns about equipment or processes related to metal dust from grinding fosters an atmosphere of collaboration and continuous improvement. When staff feel heard and valued regarding their safety input, they are more likely to engage actively in maintaining a safe workspace.

In addition, establishing recognition programs for teams or individuals who excel at adhering to safety protocols can motivate others to follow suit. Employees become champions for safe practices when they see tangible rewards for their efforts in managing risks associated with metal dust through effective use of tools like grinding dust collectors and cutting and grinding dust extraction systems. Ultimately, involving everyone in the conversation around safety leads not only to better compliance but also enhances team morale.

Conclusion

In the ever-evolving landscape of manufacturing and metalworking, managing metal dust from grinding has become a critical concern for both safety and efficiency. Comprehensive solutions are essential to mitigate the risks associated with this pervasive issue, ensuring a healthier workplace while maximizing productivity. By employing effective strategies, businesses can not only comply with industry standards but also foster a culture of safety and responsibility.

Comprehensive Solutions for Metal Dust Management

To tackle the challenges posed by metal dust from grinding, companies must invest in robust grinding dust collectors that are specifically designed for high-efficiency filtration. These systems capture harmful particles at their source, preventing them from becoming airborne and posing health risks to workers. Moreover, integrating cutting and grinding dust extraction techniques into daily operations ensures that workplaces remain clean and compliant with regulatory requirements.

Implementing a multi-faceted approach to metal dust management involves not only advanced technology but also employee training and awareness programs. Organizations should prioritize educating staff on the dangers of metal dust exposure while promoting safe practices during grinding operations. Ultimately, comprehensive solutions lead to reduced health risks and improved operational efficiency across various industries.

Advancements in Dust Control Technology

The field of dust control technology is witnessing rapid advancements aimed at improving the effectiveness of grinding dust collectors. Innovations such as smart sensors and automated cleaning systems enhance the performance of these machines, allowing for continuous operation without frequent interruptions for maintenance. Additionally, new materials used in filter design provide superior filtration capabilities, capturing even the smallest particles generated during cutting processes.

These technological improvements not only ensure better air quality but also contribute to lower operational costs over time due to reduced energy consumption and longer filter life spans. Furthermore, manufacturers are focusing on creating more compact designs that can easily fit into existing workspaces without compromising performance or efficiency. As a result, businesses can enjoy cutting-edge solutions that address their specific needs while maintaining compliance with industry standards.

NAROO’s Commitment to a Safer Environment

At NAROO, our commitment to creating safer environments extends beyond providing top-tier products; we strive to be leaders in promoting best practices for managing metal dust from grinding effectively. Our innovative range of grinding dust collectors is engineered with the latest technology advancements, ensuring optimal performance while protecting worker health across various industries. We believe that investing in effective cutting and grinding dust extraction solutions is vital for fostering workplace safety.

Moreover, NAROO actively engages in research and development efforts aimed at enhancing our product offerings continually while addressing emerging challenges within the industry. Our dedication goes hand-in-hand with educating our clients about safe practices related to metal dust management through comprehensive training programs tailored specifically for their needs. Together with our partners in safety initiatives, we’re paving the way toward cleaner workplaces where employees can thrive without fear of hazardous exposure.