Introduction

In the bustling world of metalworking shops, maintaining a clean and safe environment is paramount. Improving air quality is not just a regulatory requirement; it’s essential for the health and productivity of workers. The right metalworking dust collector can make all the difference, capturing harmful particles before they become an issue.

Improve Air Quality in Metalworking Shops

Metalworking generates various types of dust that can linger in the air, posing serious health risks to employees. Effective air quality management involves more than just opening windows; it requires a robust dust collection system designed specifically for metal working environments. By prioritizing air quality improvements, shops can create safer workspaces where employees feel valued and protected.

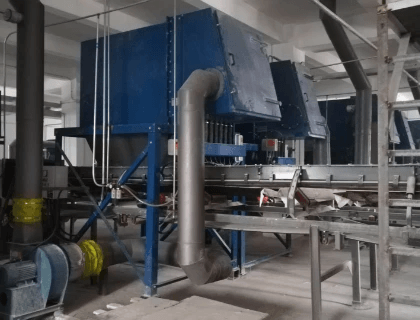

The Role of Metalworking Dust Collectors

Metalworking dust collectors serve as the frontline defense against airborne contaminants generated during machining processes. These industrial dust collectors are engineered to capture fine particles and fumes effectively, ensuring that the workspace remains clean and breathable. Without a reliable collector dust system in place, harmful dust can accumulate, leading to decreased worker efficiency and increased health risks over time.

Benefits of Investing in Dust Collection Systems

Investing in a high-quality dust filtration system offers numerous benefits beyond mere compliance with safety regulations. A well-functioning metal working shop equipped with an efficient dust collector not only enhances employee safety but also boosts productivity by reducing downtime caused by cleanup efforts or health-related absences. Additionally, proper maintenance of these systems extends their lifespan, making them a wise investment for any forward-thinking operation.

Understanding Metalworking Dust

Metalworking is a vital industry, but it comes with its own set of challenges, particularly when it comes to dust management. Understanding the types of dust generated during metal working processes is crucial for maintaining a safe and efficient environment. A robust dust collection system will not only improve air quality but also protect workers from potential health hazards associated with metalworking dust.

Types of Dust Generated in Metalworking

In any metal working shop, various types of dust are produced depending on the materials and processes used. Common sources include grinding, cutting, welding, and machining operations that generate fine particles of metals like aluminum, steel, or titanium. Each type of metalworking process creates specific dust characteristics that necessitate tailored solutions from an industrial dust collector to effectively manage and filter these particles.

Health Risks Associated with Dust Exposure

Exposure to metalworking dust poses significant health risks that should not be underestimated. Inhalation of fine particles can lead to respiratory issues such as asthma or chronic obstructive pulmonary disease (COPD), while prolonged exposure may increase the risk of more severe conditions like lung cancer or silicosis. Investing in a reliable dust collector is essential for minimizing these risks and ensuring a healthier workplace environment for all employees in the metal working shop.

Importance of Effective Dust Filtration

Effective dust filtration plays a pivotal role in maintaining air quality and protecting worker health in any industrial setting. A high-quality metalworking dust collector can capture even the smallest particles before they become airborne, significantly reducing exposure levels within the shop. By implementing an efficient dust collection system, businesses are not just complying with regulations; they’re also fostering a culture of safety that enhances productivity and employee well-being.

Choosing the Right Metalworking Dust Collector

Selecting the right metalworking dust collector is crucial for maintaining a clean and safe environment in your metal working shop. With a plethora of options available, it can be overwhelming to determine which dust collection system best fits your needs. This section will guide you through key features to consider, comparisons of industrial dust collectors, and innovative solutions offered by NAROO.

Key Features to Look For

When choosing a metalworking dust collector, there are several key features that should not be overlooked. First and foremost, look for a system with high-efficiency particulate air (HEPA) filters that ensure superior dust filtration, capturing even the tiniest particles generated during metal working processes. Additionally, consider the airflow capacity of the collector; a higher cubic feet per minute (CFM) rating means better suction power and efficiency in removing harmful dust from your workspace.

Another important feature is the ease of maintenance. A good metalworking dust collector should have accessible filter systems for quick cleaning or replacement, minimizing downtime in your shop. Lastly, noise level is also worth considering; quieter models can significantly improve working conditions without disrupting communication among workers.

Comparing Industrial Dust Collectors

When comparing industrial dust collectors, it’s essential to assess their performance metrics against your specific requirements in a metal working shop. Start by evaluating their filtration efficiency—some collectors may boast impressive stats but fall short in real-world applications due to design flaws or inadequate airflow management. It’s also wise to look into how adaptable these systems are; some models offer customizable configurations that can fit various machinery setups within your workshop.

Cost is another critical factor when making comparisons; while investing in an advanced collector dust system may seem steep initially, remember that long-term savings on health costs and increased productivity often outweigh upfront expenses. Don’t forget about manufacturer support—reliable service can make all the difference when troubleshooting issues or securing replacement parts down the line.

NAROO's Innovative Solutions

NAROO stands out in the industry with its cutting-edge approach to designing effective metalworking dust collectors tailored for modern workshops. Their products utilize advanced technology such as smart sensors that monitor air quality and automatically adjust suction levels based on real-time conditions—ensuring optimal performance at all times while conserving energy resources!

Moreover, NAROO emphasizes user-friendly designs that simplify maintenance routines; their filter systems are easily accessible and designed for quick replacements without requiring specialized tools or extensive downtime—a dream come true for busy operators! By choosing NAROO's innovative solutions, you’re not only investing in superior dust collection but also contributing to a healthier work environment.

How Dust Collection Systems Work

Dust collection systems are essential for maintaining a clean and safe environment in metalworking shops. These systems function by capturing and filtering harmful particles generated during various metalworking processes, ensuring that the air quality remains safe for workers. Understanding how these systems operate can help businesses make informed decisions about their dust management strategies.

Mechanics of Dust Collection

The mechanics of dust collection revolve around the principle of airflow and filtration. A metalworking dust collector creates a vacuum that draws in airborne particles, which are then transported through ductwork to the collector itself. Once inside, the dust is separated from the air stream using various filtration methods, ensuring that clean air is returned to the workspace while contaminants are safely contained.

Different types of filters are employed in these systems to target specific particle sizes and types generated in metal working activities. For instance, bag filters capture larger particles, while HEPA filters can trap even the smallest contaminants, making them ideal for industrial dust collectors used in sensitive environments. By effectively utilizing these filtration techniques, a dust collection system significantly reduces health risks associated with prolonged exposure to metalworking dust.

Various Dust Collector Designs

When it comes to choosing a suitable dust collector for your metal working shop, understanding the various designs available is crucial. Common designs include baghouse collectors, cyclonic separators, and cartridge collectors—each with its unique advantages tailored to specific applications within industrial settings. Baghouse collectors excel at handling large volumes of fine particulate matter, while cyclonic separators are efficient for larger debris.

Cartridge collectors offer compact solutions with high filtration efficiency and low maintenance requirements, making them an excellent choice for smaller workshops or operations with limited space. The selection of an appropriate design also depends on factors such as airflow requirements and the nature of the materials being processed in your shop. Ultimately, knowing which type best suits your needs will enhance your overall dust filtration strategy.

Integration with Metal Working Equipment

Integrating a dust collection system with existing metal working equipment is key to maximizing efficiency and effectiveness in managing airborne contaminants. Proper integration ensures that all machines generate minimal emissions during operation; this can be achieved through strategic placement of ducts and hoods directly connected to each piece of equipment generating dust or smoke. This direct approach enhances capture rates significantly compared to standalone units.

Moreover, modern industrial dust collectors often come equipped with smart technology that allows them to adjust performance based on real-time conditions within the workshop environment—this means they can ramp up suction when necessary or operate more quietly during less intensive tasks without compromising safety standards or air quality levels! Such innovations not only improve worker safety but also streamline operations by minimizing downtime caused by maintenance needs.

Maintenance of Your Dust Collector

Keeping your metalworking dust collector in prime condition is crucial for ensuring optimal performance and safety in your metal working shop. Regular maintenance not only prolongs the lifespan of your dust collection system but also enhances its efficiency, leading to better air quality and reduced health risks associated with dust exposure. Here’s how to keep your industrial dust collector running smoothly.

Routine Maintenance Tips

To maintain your metalworking dust collector, start with a regular inspection schedule. Check for any leaks or clogs that may hinder the airflow; even a small obstruction can reduce the effectiveness of your dust filtration system. Additionally, clean or replace filters according to the manufacturer's recommendations—this simple step can significantly improve the performance of your collector dust system.

Don't forget about the importance of keeping the collection containers emptied and cleaned regularly. Overfilled containers can lead to increased pressure on the system, making it less efficient at capturing metal working debris. Lastly, lubricate moving parts as required; this minimizes wear and tear while ensuring smooth operation.

Troubleshooting Common Issues

Sometimes, even the best-maintained metalworking dust collectors can run into issues that require troubleshooting. If you notice decreased suction power, first check for blockages in hoses or ducts—these are often culprits in reduced airflow within a dust collection system. If everything appears clear but problems persist, it might be time to examine the filters for dirt buildup or damage.

Another common issue is unusual noises coming from your industrial dust collector; these sounds could indicate mechanical problems such as worn-out bearings or misaligned components. Addressing these issues early can prevent more significant failures down the line. Finally, if you encounter persistent electrical problems, consult a professional technician who specializes in industrial equipment.

Extending the Life of Your Dust Collector

To extend the life of your metalworking dust collector and ensure it operates at peak efficiency, invest time in routine upkeep and proactive measures. Regularly assess airflow rates and make adjustments when necessary; maintaining optimal airflow is key to effective dust filtration and overall performance longevity. Additionally, consider implementing an upgrade plan for outdated components; modern technology often offers enhanced efficiency that older models simply can't match.

Educate all personnel operating within your metal working shop about proper usage practices—this includes understanding what materials should be collected and how to operate machinery safely around collectors. Proper training minimizes misuse that could lead to premature wear on equipment components or even accidents involving hazardous materials being improperly handled by a collector dust system.

Finally, always keep an eye on industry advancements related to industrial dust collectors; new technologies may offer solutions that improve both safety and efficiency within your workshop environment while reducing maintenance needs over time.

The Future of Dust Filtration Technology

As the metalworking industry evolves, so does the technology behind dust collection systems. Emerging trends focus on enhancing efficiency, reducing energy consumption, and improving air quality in metal working shops. The future of metalworking dust collectors promises smarter solutions that integrate seamlessly with existing equipment while addressing the growing concerns over health and environmental protection.

Emerging Trends in Dust Collection

One significant trend is the shift towards automation and smart technology in industrial dust collectors. These advanced systems utilize sensors and real-time monitoring to optimize performance, ensuring that your dust collector operates only when needed. Additionally, innovations such as modular designs allow for easier upgrades and maintenance, making it simpler to adapt your dust collection system as your metal working shop grows.

Another trend gaining traction is the use of environmentally friendly filtration materials that improve dust filtration efficiency while minimizing waste. With a focus on sustainability, manufacturers are developing biodegradable or recyclable components for their collector dust systems. This not only enhances air quality but also aligns with broader environmental goals within the industry.

The Role of Innovation in Environmental Protection

Innovation plays a crucial role in advancing environmental protection efforts across various industries, including metalworking. By investing in state-of-the-art dust collection systems, companies can significantly reduce airborne pollutants that pose health risks to workers and local communities alike. Moreover, improved filtration technologies contribute to compliance with stringent regulations aimed at safeguarding both human health and the environment.

Furthermore, innovative approaches to dust management can lead to increased operational efficiency and reduced costs over time. For instance, better-designed industrial dust collectors can capture more fine particles without requiring excessive energy input or maintenance downtime. This not only enhances workplace safety but also boosts overall productivity within metal working environments.

NAROO’s Commitment to Advanced Solutions

NAROO stands at the forefront of this technological evolution with its commitment to providing cutting-edge solutions for effective dust filtration in metalworking applications. Their range of advanced metalworking dust collectors exemplifies innovation by integrating smart features that enhance performance while prioritizing user safety and comfort. By continuously researching emerging trends and incorporating feedback from industry professionals, NAROO ensures its products meet evolving market demands.

Moreover, NAROO's dedication extends beyond just providing high-quality equipment; they actively participate in initiatives aimed at promoting sustainable practices within the industry. Their eco-friendly designs not only fulfill regulatory requirements but also demonstrate a commitment to reducing environmental impact through responsible manufacturing processes. As a leader in advanced solutions for industrial applications, NAROO remains dedicated to shaping the future of effective dust collection technology.

Conclusion

In the bustling world of metalworking, ensuring a safe and efficient environment is paramount. Investing in a robust metalworking dust collector not only enhances safety but also promotes overall productivity within your metal working shop. With the right dust collection system in place, you can effectively mitigate health risks associated with dust exposure while maintaining a clean workspace.

Enhancing Safety in Metalworking Environments

Safety should always be the top priority in any metal working shop, and effective dust filtration plays a crucial role in achieving this goal. A quality industrial dust collector can significantly reduce airborne particles that pose health risks to workers, creating a healthier atmosphere for everyone involved. By implementing an efficient dust collection system, you not only protect your employees but also foster a culture of safety that resonates throughout your organization.

The Economic Benefits of Dust Collection

The economic advantages of investing in a reliable metalworking dust collector are manifold and often underestimated. While the initial investment might seem daunting, the long-term savings from reduced health-related costs and improved worker efficiency cannot be overlooked. Moreover, an effective collector dust system can minimize equipment wear and tear by keeping machinery cleaner, leading to lower maintenance costs over time.

Making Informed Decisions for Your Workshop

Take the time to research various industrial dust collectors on the market, focusing on key features that align with your specific needs. By understanding the capabilities of different systems and opting for advanced options like NAROO’s innovative solutions, you can ensure that your workshop remains at the forefront of both productivity and safety.