Introduction

In the world of industrial operations, maintaining air quality is paramount, and a reverse air baghouse dust collector plays a pivotal role in achieving this goal. This specialized equipment is designed to capture and filter out harmful dust particles, ensuring that the air remains clean and safe for workers and the environment alike. With its advanced dust filtration capabilities, the baghouse dust collector stands out as an essential tool in various industries.

What is a Reverse Air Baghouse Dust Collector

A reverse air baghouse dust collector is a sophisticated system that utilizes bag filters to remove airborne particulates from industrial processes. Unlike traditional systems that rely on direct airflow for cleaning, this innovative technology reverses the flow of air to dislodge collected dust from the bags, enhancing efficiency and prolonging filter life. The result is a highly effective collector dust solution that ensures optimal performance even in demanding environments.

Importance of Dust Air Filtration

Dust air filtration is not just about compliance with regulations; it’s about protecting worker health and promoting safety within the workplace. Effective filtration systems like baghouse dust collectors minimize exposure to harmful contaminants, reducing respiratory issues among employees and fostering a healthier work environment. Moreover, by controlling emissions, these systems contribute significantly to environmental sustainability efforts.

Overview of Baghouse Dust Collector Operations

Baghouse dust collectors operate through a series of steps designed to capture and filter out particulates efficiently. Initially, dusty air enters the system where larger particles are separated before reaching the bag filters for finer filtration. Once collected, the reverse air technology kicks in to clean the bags without interrupting operations—making it an ideal choice for continuous processes needing reliable dust control solutions.

Understanding the Mechanics of a Baghouse Dust Collector

When it comes to effective dust air filtration, understanding the mechanics of a baghouse dust collector is essential. These systems are designed to capture and filter out airborne particulates, ensuring cleaner air for both industrial processes and the environment. By delving into the components, functionality, and innovative technologies like reverse air systems, we can appreciate how these collectors operate efficiently.

Components and Functionality

A reverse air baghouse dust collector comprises several key components that work in harmony to achieve optimal dust filtration. At its core are the bag filters—fabric tubes that trap dust particles while allowing clean air to pass through. The collector dust system also includes a fan for airflow management, a hopper for collecting debris, and a control panel for monitoring operations; together, they form an integrated solution for managing industrial emissions.

The functionality of a baghouse dust collector is straightforward yet ingenious: as dusty air enters the unit, it passes through the bag filters where particulates are captured. Over time, these filters accumulate dust, necessitating periodic cleaning to maintain efficiency. This is where reverse air technology shines; by using reverse airflow to dislodge collected particles from the bags without removing them from service, it enhances operational continuity while minimizing downtime.

How Reverse Air Technology Works

Reverse air technology in a baghouse dust collector utilizes strategically placed ducts that direct airflow opposite to the normal flow during cleaning cycles. When it's time to clean the bags, compressed air is released into these ducts; this forces accumulated dust off the filter surfaces and into the hopper below. This process not only ensures that filters remain effective but also extends their lifespan by preventing excessive buildup of particulate matter.

In contrast to traditional cleaning methods which may require shutting down operations or replacing filters more frequently, reverse air technology allows for continuous operation with minimal interruption. It's particularly beneficial in environments with high volumes of airborne contaminants where maintaining consistent performance is crucial. Ultimately, this innovative approach enhances both efficiency and effectiveness in dust filtration systems.

Benefits of Using a Bag Filter

Using a bag filter within your reverse air baghouse dust collector presents numerous advantages that elevate its performance compared to other filtration methods. Firstly, bag filters offer superior capture rates for fine particulates due to their large surface area and fabric composition; they effectively trap even microscopic particles that could otherwise escape into the atmosphere. This leads not only to cleaner indoor environments but also contributes significantly towards compliance with environmental regulations.

Additionally, implementing quality bag filters reduces energy consumption within your system because they facilitate optimal airflow while minimizing resistance—this means your fan doesn't have to work overtime! Furthermore, regular maintenance becomes easier since many modern bags are designed for quick replacements or cleaning cycles using advanced technologies like those found in NAROO products focused on innovation in air purification solutions.

Lastly, investing in high-quality bag filters can lead directly to improved worker safety by reducing exposure levels of harmful airborne substances—creating healthier workplaces should always be at the forefront of any industrial operation's objectives! In summary, utilizing effective bag filtration not only enhances operational efficiency but also contributes positively towards employee wellbeing and environmental stewardship.

The Role of Dust Filtration in Industry

Dust filtration is not just a luxury; it's a necessity for many industries. A reverse air baghouse dust collector plays a pivotal role in maintaining clean air and ensuring compliance with environmental regulations. From manufacturing to food processing, the need for effective dust air filtration has never been more critical.

Essential Industries Utilizing Dust Collectors

Several essential industries rely heavily on dust collectors to maintain operational efficiency and safety. The construction industry, for instance, uses baghouse dust collectors to manage silica dust generated during various processes. Similarly, manufacturers of pharmaceuticals and food products utilize these systems to ensure that their environments remain uncontaminated by harmful particulates.

In the metalworking sector, a collector dust system is crucial for capturing metal shavings and fumes that can pose health risks to workers. Additionally, industries involved in woodworking depend on advanced bag filters to mitigate wood dust hazards effectively. Ultimately, the versatility of dust filtration technologies makes them indispensable across diverse sectors.

Impact on Worker Safety and Health

The impact of effective dust control on worker safety cannot be overstated; it’s often a matter of life or death in some industries. By utilizing a reverse air baghouse dust collector, companies can significantly reduce airborne contaminants that lead to respiratory issues among employees. This proactive approach not only enhances workplace safety but also boosts employee morale by demonstrating a commitment to their well-being.

Moreover, effective dust filtration directly correlates with lower rates of occupational diseases such as silicosis or asthma caused by prolonged exposure to fine particles. When workers breathe cleaner air filtered through advanced systems like baghouse dust collectors, they are less likely to experience health complications over time. Thus, investing in proper dust collection solutions translates into healthier work environments and reduced healthcare costs.

Environmental Benefits of Effective Dust Control

The environmental benefits of using efficient dust filtration systems extend far beyond individual workplaces; they contribute significantly to global sustainability efforts as well. Implementing systems like reverse air baghouse dust collectors helps minimize the release of particulate matter into the atmosphere, which is vital for combating air pollution. Cleaner emissions not only protect local ecosystems but also contribute positively towards meeting regulatory standards aimed at reducing environmental impact.

Furthermore, proper management of industrial waste through effective collector dust systems can lead to improved waste disposal practices and recycling efforts within various sectors. With growing concerns about climate change and environmental degradation, businesses adopting robust bag filter technologies are taking steps toward greener operations that benefit both society and nature alike. In this way, investing in quality dust filtration is not just good business practice—it's an ethical imperative.

Maintenance Best Practices for Baghouse Dust Collectors

Maintaining a reverse air baghouse dust collector is crucial for ensuring optimal performance and longevity. Regular upkeep not only extends the life of your dust collector but also enhances its efficiency in dust air filtration. Implementing a structured maintenance routine can prevent costly downtimes and keep your operations running smoothly.

Regular Inspection and Cleaning

Regular inspection and cleaning are the cornerstones of effective baghouse dust collector maintenance. It's important to check the bag filter condition frequently, as worn or damaged filters can significantly reduce the efficiency of your dust filtration system. Cleaning schedules should be established based on your specific operational environment, with more frequent checks in high-dust areas to ensure that the collector dust does not accumulate excessively.

During inspections, pay attention to any signs of leaks or blockages that could hinder airflow through the system. A reverse air baghouse dust collector relies on proper airflow to function effectively; any disruptions can lead to increased energy consumption and reduced filtration effectiveness. Keeping a log of inspections will help you track performance over time and identify potential issues before they escalate.

Common Issues and Troubleshooting

Even with regular maintenance, issues may arise with your baghouse dust collector that require troubleshooting. One common problem is excessive pressure drop across the filters, which could indicate clogging or damage within the bag filter itself. If you notice higher energy usage or diminished performance, it's time to investigate further; this might involve visually inspecting each filter for tears or significant wear.

Another frequent issue involves the reverse air mechanism itself; if it fails to operate correctly, it may lead to inadequate cleaning cycles for the filters. This can result in a buildup of collector dust that hampers overall system efficiency. Troubleshooting these components requires familiarity with both mechanical systems and electronic controls—don’t hesitate to consult professional resources if needed!

Importance of Quality Filters

The quality of filters used in a reverse air baghouse dust collector cannot be overstated; they are pivotal for effective dust air filtration and overall system performance. Investing in high-quality bag filters ensures better capture rates for fine particles while providing longer service life compared to lower-quality options. Using subpar filters might save money initially but can lead to increased maintenance costs down the line due to frequent replacements.

Moreover, quality filters contribute significantly to worker safety by reducing airborne contaminants in industrial environments—a key benefit when considering health regulations and workplace standards. Ensuring that you have reliable filters means fewer interruptions due to clogs or failures, allowing your operations to run efficiently without unnecessary downtime related to maintenance issues concerning your bag house equipment.

Advanced Technologies in Dust Filtration

The world of dust filtration is evolving rapidly, with innovative technologies enhancing the efficiency and effectiveness of dust collectors. Among these advancements, the reverse air baghouse dust collector stands out for its superior design and operational benefits. As industries seek to improve air quality and worker safety, these cutting-edge solutions are becoming essential for effective dust air filtration.

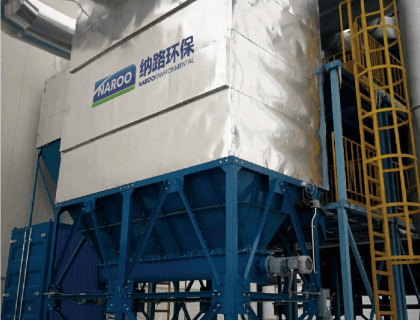

Innovations from NAROO in Air Purification

NAROO has been at the forefront of innovations in air purification, particularly in developing advanced bag filters that optimize the performance of dust collectors. Their proprietary filtration technology enhances the ability of a baghouse dust collector to capture fine particulate matter, ensuring cleaner air output while minimizing energy consumption. With a focus on sustainability, NAROO’s designs not only improve operational efficiency but also contribute significantly to environmental protection by reducing harmful emissions.

Integration of Smart Technology

Smart technology is revolutionizing how we approach dust filtration systems like reverse air baghouse dust collectors. Integrating sensors and data analytics into these systems allows for real-time monitoring of filter performance and airflow rates, which can lead to proactive maintenance and reduced downtime. This intelligent approach not only enhances the overall functionality of collector dust systems but also provides valuable insights into operational efficiencies and potential areas for improvement.

Future Trends in Dust Collector Design

Looking ahead, several trends are set to shape the future of baghouse dust collector design. The shift towards automation will likely dominate discussions about new models, as manufacturers aim to create more user-friendly systems that require less manual intervention while improving performance metrics like filter life and energy use. Additionally, eco-friendly materials will become increasingly important as industries strive to meet stringent environmental regulations while maintaining effective dust filtration capabilities.

Choosing the Right Dust Collector for Your Needs

When it comes to selecting the right dust collector, the choices can be overwhelming. Understanding your specific needs and the characteristics of various systems is crucial to making an informed decision. The right reverse air baghouse dust collector can ensure efficiency, safety, and compliance in your operations while optimizing dust air filtration.

Factors to Consider When Selecting a Collector

Several factors play a pivotal role in choosing the best dust collector for your facility. First, consider the type and volume of dust generated in your processes; different materials require specific filtration capabilities from a baghouse dust collector. Additionally, evaluate space constraints and airflow requirements to ensure that your chosen collector dust system fits seamlessly into your existing setup.

Another critical aspect is maintenance needs; some systems demand more upkeep than others, which can impact operational costs over time. Be sure to assess energy consumption as well—efficient models like reverse air baghouse dust collectors often provide better long-term savings through reduced power usage. Finally, don’t overlook regulatory compliance; selecting a system that meets local environmental standards is essential for avoiding fines and ensuring worker health.

Comparing Reverse Air and Traditional Systems

When comparing reverse air systems with traditional options, there are notable differences that can influence your choice significantly. Reverse air baghouse dust collectors utilize innovative technology to clean filters without interrupting airflow, making them ideal for continuous operations where downtime must be minimized. Traditional systems may rely on manual or mechanical cleaning methods that can lead to inefficiencies or increased wear on components.

Moreover, reverse air technology typically offers superior filtration performance due to its ability to handle varying dust loads effectively while maintaining lower pressure drops across filters. This translates into longer filter life and reduced operating costs over time—a win-win situation for any facility looking at long-term investments in their dust filtration solutions. Ultimately, understanding these distinctions will help you select a system that aligns with both operational demands and budget constraints.

Cost vs. Benefit Analysis

Conducting a cost versus benefit analysis is essential when deciding on a new collector dust system—especially given the range of options available today. While initial investment costs for advanced systems like reverse air baghouse dust collectors may be higher than traditional models, their longevity and efficiency often justify the expense over time through reduced maintenance costs and improved energy efficiency.

Additionally, consider how effective dust control impacts overall productivity; fewer interruptions due to filter cleaning or equipment failure mean smoother operations and less downtime, which equates to savings in labor costs as well as potential revenue loss from halted production lines. In this light, investing in high-quality bag filters or advanced technologies may ultimately yield significant returns on investment by enhancing both performance and safety standards within your facility.

Conclusion

In summary, the operations of a reverse air baghouse dust collector are crucial for maintaining clean and safe industrial environments. By effectively filtering dust particles through advanced bag filter technology, these systems not only enhance air quality but also contribute to overall operational efficiency. The importance of dust air filtration cannot be overstated, as it plays a vital role in protecting both workers and the environment from harmful pollutants.

Key Takeaways on Dust Collector Operations

Understanding the functionality of a baghouse dust collector is essential for any industry that generates airborne particles. Regular maintenance and the use of quality filters can significantly prolong the life of a dust collector while ensuring optimal performance. Ultimately, investing in an efficient collector dust system like a reverse air baghouse dust collector is beneficial for enhancing worker safety and reducing environmental impact.

The Future of Air Filtration Technology

The future of dust filtration looks promising with ongoing innovations that aim to improve efficiency and sustainability. Advances in smart technology will likely enable real-time monitoring and automated adjustments to optimize performance in various settings. As industries continue to prioritize cleaner operations, we can expect even more sophisticated solutions in air filtration technology, including enhanced designs for baghouse dust collectors.

How NAROO Leads the Way in Innovation

NAROO stands at the forefront of innovation in air purification technologies, offering cutting-edge solutions for effective dust control. Their commitment to research and development ensures that their products not only meet but exceed industry standards for performance and reliability. By integrating advanced features into their reverse air baghouse dust collectors, NAROO is setting new benchmarks for what effective dust filtration should look like.