Introduction

In the world of industrial operations, the baghouse system plays a crucial role in maintaining air quality and ensuring compliance with environmental regulations. This dusty air filter is not just a piece of equipment; it’s a vital component that protects both workers and the environment from harmful dust emissions. Understanding its importance allows businesses to prioritize effective dust air filtration, which is essential for operational efficiency and safety.

Understand Your Baghouse System's Importance

The baghouse system serves as the first line of defense against airborne pollutants, capturing fine particles that could otherwise compromise air quality. A well-functioning baghouse dust collector minimizes risks associated with exposure to harmful dust, safeguarding employee health and meeting regulatory standards. Recognizing this importance encourages proactive measures in maintaining and optimizing your air filter system.

Common Issues with Dust Air Filtration

Despite its significance, many facilities encounter common issues with their dusty air filters that can lead to inefficiencies. Frequent problems include clogging of dust filters, reduced airflow, and inadequate collection of fine particulate matter—issues that can severely impact overall performance. Identifying these challenges early on is key to ensuring that your bag house operates at peak efficiency.

Benefits of Optimizing Your Baghouse

Optimizing your baghouse not only improves dust collection efficiency but also extends the lifespan of your equipment and reduces operational costs. Enhanced performance translates into lower energy consumption and fewer maintenance interventions, ultimately benefiting your bottom line. By investing time in refining your dust air filtration processes, you create a cleaner work environment while promoting sustainability within your operations.

Assess Your Baghouse Dust Collector Efficiency

Evaluating the efficiency of your baghouse system is crucial for maintaining optimal dust air filtration. A well-functioning baghouse dust collector not only reduces emissions but also saves you money in the long run by minimizing energy consumption and maintenance costs. To ensure your dusty air filter is performing at its best, regular performance evaluations should be part of your operational routine.

Evaluating Dust Collector Performance

To evaluate the performance of your baghouse system, start by measuring key metrics such as airflow rates, pressure drops, and collection efficiency. Monitoring these factors will help you determine if your dust filters are working effectively or if there's room for improvement. Remember, an efficient bag house should maintain a balance between air flow and filtration to avoid overloading the collector dust capacity.

Identifying Areas for Improvement

Once you've evaluated your dust collector's performance, it's time to identify specific areas needing improvement within the system. Look for signs such as increased pressure drops or reduced airflow that may indicate clogged filters or malfunctioning components in the air filter system. Additionally, consider analyzing historical data on maintenance and operational trends to pinpoint recurring issues that could be addressed with targeted upgrades or adjustments.

Tools for Measuring Efficiency

Several tools can aid in measuring the efficiency of your baghouse dust collector effectively. Flow meters can provide real-time data on airflow rates while differential pressure gauges help monitor pressure drops across filters to ensure they aren't becoming overloaded with collector dust. Furthermore, advanced monitoring systems equipped with sensors can offer insights into filter conditions and alert you when maintenance is due—making it easier to keep your dusty air filter functioning optimally.

Regular Maintenance for Optimal Performance

Maintaining your baghouse system is crucial for ensuring optimal performance and longevity. Regular maintenance not only prevents costly breakdowns but also enhances the efficiency of your dusty air filter. By prioritizing routine checks and upkeep, you can keep your dust air filtration system running smoothly and effectively.

Importance of Routine Inspections

Routine inspections are the backbone of a well-functioning baghouse dust collector. By regularly checking for wear and tear, you can identify potential issues before they escalate into major problems that disrupt operations. Additionally, these inspections help ensure that all components are working harmoniously to minimize collector dust, ultimately improving the overall efficiency of your air filter system.

Cleaning Techniques for Dust Filters

Proper cleaning techniques for dust filters are essential in maintaining a high-performance baghouse system. Techniques such as pulse jet cleaning or manual shaking can effectively dislodge accumulated dust from filters, allowing them to operate at peak efficiency. Implementing a systematic cleaning schedule will help extend the life of your dust filters while reducing pressure drop across the baghouse, which is vital for effective dust air filtration.

Scheduling Maintenance Effectively

Scheduling maintenance effectively can make all the difference in keeping your bag house operating smoothly. Consider creating a calendar that outlines regular inspections, cleanings, and any necessary upgrades to ensure no aspect of maintenance is overlooked. By staying proactive with scheduling, you can avoid unexpected downtime and maintain optimal performance from your baghouse dust collector.

Upgrading Your Air Filter System

Upgrading your air filter system is a strategic move that can significantly enhance the efficiency of your baghouse system. With advancements in technology, dusty air filters are becoming more effective at capturing particulate matter, reducing environmental impact while improving workplace safety. Investing in an upgraded dust air filtration system not only boosts performance but also extends the lifespan of your baghouse dust collector.

New Technologies in Dusty Air Filters

The landscape of dusty air filters has transformed dramatically with innovations that promise higher efficiency and lower energy consumption. New materials and designs are being introduced, such as nanofiber technology, which captures smaller particles than traditional filters can manage. Additionally, smart monitoring systems are now available, allowing real-time tracking of filter performance and alerting operators to potential issues before they escalate.

These new technologies not only improve the effectiveness of dust collection but also streamline maintenance processes for the baghouse system. For instance, some advanced filters come with self-cleaning capabilities that reduce downtime and labor costs associated with manual cleaning. As industries continue to evolve, staying ahead with cutting-edge solutions will be crucial for maintaining optimal dust filtration.

Benefits of Advanced Filter Media

Advanced filter media offer numerous benefits that can transform how your baghouse dust collector operates. These materials are designed to enhance airflow while maximizing particle capture efficiency, resulting in cleaner exhaust and a healthier work environment. By using high-performance filter media, you can significantly reduce the amount of collector dust released into the atmosphere.

Moreover, advanced media often require less frequent replacement compared to traditional options; this means less waste and lower operational costs over time. The durability of these materials also contributes to extended service life for your air filter system—saving both time and money on maintenance schedules. In essence, switching to advanced filter media is an investment that pays dividends through improved performance and reduced long-term expenses.

Cost-Effectiveness of Upgrades

When considering upgrades for your baghouse system's air filter system, it’s essential to evaluate their cost-effectiveness thoroughly. While initial investment costs may seem daunting, many facilities find that enhanced efficiency leads to substantial savings in energy consumption and operational expenses over time. By optimizing your dusty air filter setup with modern solutions, you’ll likely see a decrease in utility bills as well as fewer disruptions due to maintenance needs.

Additionally, investing in better technology can lead to compliance with stricter environmental regulations—potentially avoiding costly fines or penalties down the line. The long-term benefits often outweigh initial expenditures when you factor in improved worker safety and productivity from reduced exposure to harmful particulates like collector dust. Ultimately, upgrading your dust filters is not just about keeping up with trends; it’s about future-proofing your operations against evolving industry demands.

Enhancing Dust Air Filtration Processes

In the quest for cleaner air and more efficient operations, enhancing dust air filtration processes is essential for any baghouse system. By implementing effective techniques, optimizing processes, and training staff on best practices, facilities can significantly reduce collector dust and improve overall performance. Let's dive into some strategies that can transform your dusty air filter setup into a powerhouse of efficiency.

Techniques for Reducing Collector Dust

To tackle the persistent issue of collector dust in your baghouse dust collector, adopting specific techniques is crucial. One effective method involves improving the airflow dynamics within your air filter system; ensuring proper duct sizing and minimizing bends can help maintain optimal velocity and prevent dust accumulation. Additionally, regular monitoring of differential pressure across filters allows you to identify blockages early, ensuring that your dusty air filter operates at peak efficiency.

Another technique involves utilizing pre-filters or cyclonic separators to capture larger particles before they reach the main baghouse system. This not only prolongs the life of your dust filters but also enhances overall filtration efficiency by reducing the load on primary filters. Lastly, consider integrating automated cleaning systems that utilize pulse-jet technology to dislodge collected dust without interrupting operations—keeping your baghouse running smoothly.

Process Optimization Strategies

Optimizing processes within your baghouse system can lead to significant improvements in performance and reductions in operating costs. Start by analyzing existing workflows to identify bottlenecks or inefficiencies that could contribute to excess collector dust generation. By streamlining these processes—whether through equipment upgrades or procedural changes—you'll enhance the overall effectiveness of your dusty air filter setup.

Implementing real-time monitoring systems is another strategy worth considering; these tools allow for constant assessment of key performance indicators related to airflow, pressure drops, and filter conditions. With this data at hand, you can make informed adjustments as needed—ensuring that your baghouse dust collector remains efficient under varying operational conditions. Moreover, employing predictive maintenance techniques can help anticipate failures before they occur, saving time and resources while maintaining optimal filtration performance.

Training Staff on Best Practices

No matter how advanced your baghouse system may be, its success ultimately hinges on the people operating it; therefore, training staff on best practices is paramount for effective dust air filtration management. Begin with comprehensive onboarding sessions focused on understanding how each component works together within the entire air filter system—this foundational knowledge empowers employees to troubleshoot issues confidently as they arise.

Regular refresher courses should also be implemented to keep staff updated on new technologies or changes in procedures related to maintaining bag house efficiency. Encourage a culture of continuous improvement where employees feel empowered to share insights or suggest modifications based on their experiences with the equipment—they are often closest to potential issues! In doing so, you'll create a knowledgeable team equipped with practical skills necessary for optimizing both daily operations and long-term performance.

Innovations from NAROO for Baghouses

In the ever-evolving landscape of dust air filtration, NAROO stands out as a pioneer in enhancing baghouse systems. Their innovative solutions not only tackle common challenges associated with dusty air filters but also set new benchmarks for efficiency and performance. By integrating advanced technologies, NAROO is redefining what it means to optimize a baghouse dust collector.

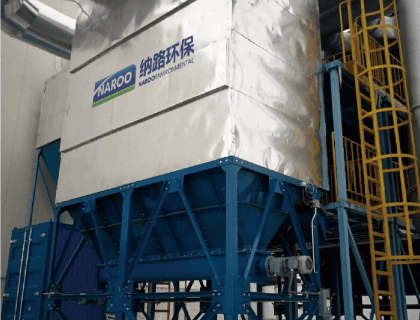

Overview of NAROO's Solutions

NAROO offers a range of cutting-edge solutions designed specifically for baghouse systems, focusing on maximizing efficiency while minimizing downtime. Their products include high-performance dust filters that are engineered to capture even the finest particles, ensuring cleaner air and improved operational reliability. With features like self-cleaning mechanisms and enhanced filter media, these solutions significantly reduce collector dust buildup and extend the lifespan of the air filter system.

Moreover, NAROO’s commitment to sustainability shines through in their designs, which prioritize energy efficiency without compromising filtration effectiveness. This means that businesses can enjoy both environmental benefits and cost savings when upgrading their dusty air filters with NAROO technology. As industries increasingly prioritize eco-friendly practices, adopting such innovations becomes not just an option but a necessity.

Case Studies and Success Stories

NAROO has accumulated an impressive portfolio of case studies demonstrating the transformative impact of their innovations on various baghouse applications. One notable success story involves a manufacturing plant that struggled with excessive collector dust causing frequent shutdowns and costly maintenance interventions. After implementing NAROO's advanced air filter system, the plant reported a 40% reduction in downtime due to improved filtration efficiency.

Another case highlights how a construction site benefited from upgraded dusty air filters featuring NAROO's proprietary technology. The site achieved compliance with stringent environmental regulations while simultaneously reducing operating costs by 30%. These success stories exemplify how investing in innovative solutions can lead to substantial operational improvements in any bag house environment.

Future Trends in Dust Management

Looking ahead, the future of dust management is poised for exciting advancements driven by continuous innovation from companies like NAROO. Emerging trends indicate a shift toward smart technologies integrated within baghouse systems, allowing for real-time monitoring and automated adjustments based on changing conditions within the facility. This proactive approach will not only enhance dust air filtration performance but also provide valuable data insights for ongoing optimization efforts.

Additionally, there is growing interest in biodegradable filter media that align with sustainability goals while maintaining high filtration standards—an area where NAROO is already conducting research and development initiatives. As industries adapt to stricter regulations around emissions and waste disposal, embracing such forward-thinking solutions will be crucial for maintaining compliance without sacrificing productivity or profitability.

Conclusion

In wrapping up our exploration of optimizing your baghouse system, it’s clear that maintaining an efficient dust air filtration process is vital for operational success and compliance. The benefits of a well-functioning baghouse dust collector extend beyond mere cleanliness; they include improved air quality, enhanced worker safety, and reduced operational costs. By focusing on key takeaways from this guide, you can ensure your dusty air filter system is running at peak performance.

Key Takeaways for Baghouse Efficiency

First and foremost, understanding the importance of regular maintenance cannot be overstated when it comes to your baghouse system. Regular inspections and cleaning techniques for dust filters not only prolong the life of your equipment but also significantly enhance its efficiency in capturing collector dust. Additionally, identifying areas for improvement through performance evaluations will allow you to target specific issues and implement effective solutions.

The Role of Innovation in Air Filtration

Innovation plays a crucial role in enhancing the effectiveness of any air filter system, including those used in baghouses. New technologies in dusty air filters are constantly emerging, offering advanced filter media that can capture more particles with less energy consumption. Embracing these innovations not only boosts your bag house’s efficiency but also positions your operations as environmentally responsible—a win-win scenario!

Next Steps for Optimizing Your System

To optimize your baghouse system further, consider conducting a thorough assessment of its current performance using specialized tools designed to measure efficiency accurately. From there, prioritize upgrades that incorporate the latest advancements in filtration technology—this could mean investing in better dust filters or implementing process optimization strategies that reduce collector dust generation altogether. Finally, don’t forget to train staff on best practices; an informed team is essential for maintaining optimal performance across all aspects of your air filtration processes.