Introduction

In the world of industrial operations, dust collection is not just a matter of cleanliness; it’s an essential component of workplace safety and efficiency. Understanding the various types of dust collectors available can help businesses select the right industrial dust collector that meets their specific needs. With the right dust collection industrial system in place, companies can ensure a healthier environment for their employees while also enhancing productivity.

Understanding Dust Collection Essentials

Dust collection is a critical process that involves capturing airborne particles generated during manufacturing and other industrial activities. The essential goal is to remove these particles from the air to maintain cleanliness and protect equipment and personnel from harmful exposure. By grasping the fundamentals of dust collection systems, including how they operate and their components, businesses can make informed decisions about which type of dust collector is best suited for their operations.

Importance of Effective Dust Control

Effective dust control is vital for several reasons, including compliance with health regulations, improving air quality, and increasing operational efficiency. Inadequate dust management can lead to respiratory issues among workers and contribute to machinery wear-and-tear due to accumulated debris. Therefore, investing in an efficient industrial air purification system not only safeguards employee health but also enhances overall productivity by creating a cleaner work environment.

Overview of Dust Collecting Systems

Dust collecting systems come in various shapes and sizes, each designed to tackle specific types of airborne contaminants effectively. From bag houses that utilize specialized filters to capture fine particles to portable dust collectors that provide flexibility on job sites, there are numerous options available for different applications. Understanding these systems allows organizations to choose an effective solution tailored to their unique requirements while ensuring optimal performance in managing airborne pollutants.

Exploring Different Types of Dust Collectors

Each type serves a unique purpose and offers distinct advantages, making it crucial to choose the right industrial dust collector for your needs. This section will delve into three popular types: bag house systems, cyclone collectors, and portable dust collectors.

Overview of Bag House Systems

Bag house systems are one of the most widely used types of dust collectors in industrial settings. They consist of a series of fabric filter bags that capture airborne particles as air passes through them, effectively removing dust from the environment. The efficiency of these systems makes them ideal for applications requiring high filtration rates and large volumes of air, solidifying their place in the realm of industrial dust collection.

One significant advantage of bag house systems is their ability to handle varying particle sizes while maintaining optimal airflow. Regular maintenance ensures that the air filter for dust remains effective over time, allowing for consistent performance in demanding environments. Moreover, with advancements in technology, modern bag houses can be equipped with automatic cleaning mechanisms that enhance operational efficiency and reduce downtime.

Cyclone Collectors: A Powerful Solution

Cyclone collectors are another powerful solution within the spectrum of types of dust collectors available today. These systems utilize centrifugal force to separate larger particles from the air stream before they reach any filtration medium—making them particularly effective for coarse materials like wood chips or metal shavings. Their design allows for minimal resistance to airflow, which can be beneficial when integrating with other components in an industrial air purification system.

One key benefit is their low maintenance requirements compared to traditional bag house systems; since there are no filters to replace regularly, operational costs can be significantly reduced over time. Additionally, cyclone collectors can often be used as pre-filters before finer filtration units like bag houses or HEPA filters—enhancing overall system performance in an industrial dust collection system setup. This versatility makes them suitable for various applications across multiple industries.

Portable Dust Collectors for Flexibility

For those who require mobility without sacrificing performance, portable dust collectors offer an excellent solution among types of dust collectors available on the market today. These compact units are designed to be easily moved around job sites or workshops while still providing efficient dust collection capabilities wherever they are needed most. Their flexibility allows operators to address localized sources of airborne particles effectively.

Portable models often come equipped with robust air filters specifically designed for optimal particle removal efficiency—ensuring clean air quality even in challenging environments such as construction sites or manufacturing floors. Furthermore, many portable units feature user-friendly designs that simplify setup and operation—making them accessible even for those new to using an industrial dust collector system. As industries continue evolving towards more adaptable solutions, portable options will undoubtedly remain a popular choice.

The Role of Industrial Air Purification Systems

Industrial air purification systems play a crucial role in maintaining a safe and healthy workspace by filtering out harmful particles and pollutants from the air. These systems complement various types of dust collectors, including bag houses and portable dust collectors, to enhance overall air quality. By integrating an effective industrial dust collection system with an air purification strategy, businesses can significantly reduce airborne contaminants and improve worker productivity.

Enhancing Air Quality in Workspaces

The importance of clean air cannot be overstated, especially in industrial environments where exposure to dust and other pollutants can lead to serious health issues. An effective industrial air purification system works hand-in-hand with dust collection systems to remove particulate matter from the atmosphere, creating a safer workspace for employees. By utilizing advanced air filters for dust removal, these systems ensure that the air remains free from harmful substances while also minimizing downtime caused by health-related absences.

Moreover, improved air quality has been linked to enhanced cognitive function and overall workplace morale. Employees operating in cleaner environments tend to experience fewer respiratory problems and are less likely to suffer from fatigue or irritability caused by poor indoor air quality. Therefore, investing in both an industrial dust collector and an efficient air purification system is not just beneficial for compliance but also essential for fostering a productive work culture.

Best Practices for Implementation

To maximize the effectiveness of an industrial air purification system, businesses should consider several best practices during implementation. First, it’s essential to assess the specific needs of the facility; this includes identifying potential sources of airborne contaminants and determining which types of dust collectors will work best alongside the chosen purification system. This tailored approach ensures that both systems operate efficiently together without redundancy.

Regular maintenance is another critical aspect that cannot be overlooked when implementing these systems. Routine checks on both the industrial dust collector and the air filtration units will help identify wear-and-tear issues before they escalate into costly repairs or replacements. Additionally, training staff on how to monitor these systems effectively can lead to better adherence to maintenance schedules and improved overall performance.

Lastly, continuous monitoring of indoor air quality helps gauge the effectiveness of installed systems over time. Using sensors that track particulate levels allows facilities managers to make data-driven decisions about when upgrades or adjustments are necessary—ensuring that workers always breathe clean air while staying compliant with industry regulations.

Leading Brands in Industrial Air Purification

When it comes to selecting an industrial air purification system, several leading brands stand out due to their proven reliability and innovative technology solutions. Companies like Camfil offer robust options designed specifically for heavy-duty applications where high-efficiency particulate filters (HEPA) are crucial for capturing fine particles generated by various types of dust collectors such as bag houses or cyclone collectors.

Another notable name is Donaldson Torit, known for their comprehensive range of filtration products tailored towards different industries’ unique needs—including those requiring specialized solutions like fume extraction alongside standard dust collection capabilities. Their commitment to research ensures that their products incorporate cutting-edge technology designed not only for efficiency but also sustainability.

Lastly, AAF International provides versatile solutions adaptable across multiple sectors—from manufacturing plants needing robust filtration methods down through smaller operations requiring portable units capable of handling diverse challenges posed by varying types of particulates found within different environments.

Features of an Effective Dust Collection Industrial System

When it comes to industrial dust collection systems, understanding the key components is crucial for ensuring optimal performance and efficiency. An effective dust collector is composed of several integral parts, including air filters for dust, collection hoppers, and exhaust fans. These components work in harmony to capture airborne particles and maintain a clean workspace while protecting worker health.

Key Components of Modern Systems

Modern dust collectors have evolved significantly from their predecessors, incorporating advanced technologies that enhance their functionality. For instance, bag house systems utilize fabric filters to trap fine dust particles efficiently while allowing clean air to pass through. Additionally, many industrial dust collection systems are equipped with automated cleaning mechanisms that ensure the air filter for dust remains clear and operational.

Another essential component is the control system that monitors airflow and pressure within the system, adjusting operation as needed to maintain peak efficiency. This integration of technology not only improves the effectiveness of various types of dust collectors but also reduces energy consumption—a win-win for both productivity and cost management. Overall, understanding these key components helps businesses select the right industrial dust collector tailored to their specific needs.

Importance of Proper Maintenance

Proper maintenance is paramount in ensuring that any industrial air purification system operates at its best over time. Regular inspections and timely replacements of worn-out parts can prevent unexpected breakdowns that may lead to costly downtimes or inefficient operations in your dust collection industrial setup. Keeping an eye on filters—especially in bag house systems—ensures they remain effective at capturing pollutants without straining the system.

In addition to routine checks, implementing a maintenance schedule can extend the lifespan of your equipment significantly while enhancing overall performance. Neglecting maintenance might result in increased energy usage due to clogged filters or malfunctioning components; after all, a well-maintained system runs smoother and saves you money in the long run! So don't skimp on those upkeep tasks; they are vital for maximizing your investment in an industrial dust collector.

Efficiency vs. Cost: What to Consider

When evaluating different types of dust collectors for your business needs, balancing efficiency with cost becomes a critical consideration. While some high-efficiency models may come with a higher upfront price tag, they often yield significant savings over time through reduced energy consumption and lower maintenance costs—making them worth every penny! Conversely, opting for cheaper alternatives might lead you down a path filled with frequent repairs or inefficiencies that ultimately cost more than anticipated.

It's also essential to consider how various features impact both initial investment and long-term operational costs when selecting an industrial dust collection system or an air filter for dust removal. For example, investing in advanced filtration technologies may provide better performance but could require more resources upfront compared to simpler models like basic cyclone collectors or portable options. Striking this balance ensures you choose not just any system but one that meets your unique needs effectively without breaking the bank!

Bag House Dust Collectors: An In-Depth Look

Bag house dust collectors are a prominent choice in the realm of industrial dust collection systems, known for their efficiency and effectiveness in managing airborne particles. These systems utilize fabric filters to capture dust and particulates from the air, making them essential for maintaining clean environments in various industries. Understanding how bag houses operate can help businesses make informed decisions about their dust collection needs.

How Bag Houses Capture Dust

At the core of a bag house dust collector is its unique filtration system, which consists of multiple fabric bags that filter out dust from the air stream. As air laden with particles enters the collector, it passes through these bags, which act as an air filter for dust, trapping contaminants while allowing clean air to exit. Over time, collected dust builds up on the exterior of the bags, which can be removed through automated cleaning mechanisms to ensure optimal performance.

Bag houses can handle a wide range of particulate sizes and types, making them versatile across different applications. The design allows for high airflow rates while maintaining low pressure drops, enhancing overall efficiency in industrial settings. This makes bag house systems a preferred choice among various types of dust collectors available today.

Advantages Over Traditional Collectors

One major advantage of bag house systems over traditional collectors is their superior filtration capabilities; they can achieve much finer filtration levels than many other types of dust collectors. This means they are more effective at capturing smaller particles that could otherwise escape into the atmosphere or interfere with production processes. Furthermore, modern bag houses often come equipped with advanced monitoring technology that ensures optimal operation and alerts operators to maintenance needs before issues arise.

Another significant benefit is their energy efficiency; many bag house designs optimize airflow and minimize energy consumption compared to older models or alternative systems like cyclone collectors. Not only does this reduce operational costs but it also aligns with sustainability goals by lowering carbon footprints associated with industrial processes. Additionally, their modular design allows for scalability—businesses can expand their systems as needed without extensive overhauls.

Common Applications in Various Industries

Bag house dust collectors are widely used across numerous industries due to their adaptability and effectiveness in controlling airborne pollutants. In manufacturing environments such as woodworking or metalworking shops, these systems play a crucial role in ensuring compliance with health regulations by capturing harmful particulate matter generated during production processes. Similarly, they are essential in food processing plants where cleanliness is paramount; here they help maintain safe working conditions while preserving product quality.

In construction sites and demolition projects where fine debris can pose serious health risks, bag houses provide an efficient solution for controlling airborne particles generated by activities like cutting or grinding materials. The pharmaceutical industry also benefits from these systems; stringent cleanliness standards necessitate robust filtration solutions that only high-quality industrial dust collection systems can provide effectively. Overall, whether it's heavy manufacturing or delicate pharmaceuticals, bag house collectors prove indispensable across diverse sectors.

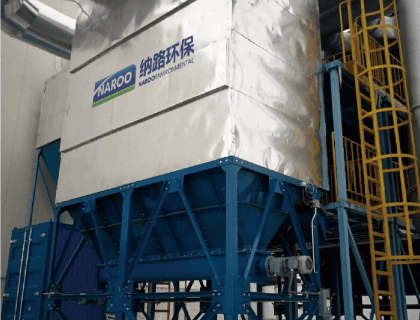

Innovative Solutions from NAROO

NAROO has revolutionized the dust collection industrial landscape with its innovative solutions that cater to diverse industrial needs. By focusing on advanced technology and user-friendly designs, NAROO ensures that their dust collectors not only meet but exceed industry standards. Their approach emphasizes efficiency, sustainability, and adaptability, making them a leader in the field of industrial dust collection systems.

NAROO’s Approach to Dust Removal

NAROO’s approach to dust removal is centered around creating effective and efficient industrial dust collectors that can handle various types of dust collectors for different applications. They utilize state-of-the-art technology combined with high-performance air filters for dust, ensuring optimal air quality in any workspace. By prioritizing both functionality and ease of use, NAROO’s solutions are designed to provide seamless integration into existing systems while maintaining high levels of performance.

Case Studies: Successful Implementations

Several case studies highlight the successful implementations of NAROO's innovative solutions across various industries. For instance, a manufacturing facility faced challenges with airborne particulate matter; after integrating NAROO's bag house system into their operations, they reported a significant reduction in dust levels and improved employee health conditions. Another example includes a woodworking shop that adopted an industrial air purification system from NAROO, resulting in cleaner air and enhanced productivity due to fewer disruptions caused by excessive dust.

The Future of Dust Collection Technology

The future of dust collection technology looks promising as companies like NAROO continue to push the boundaries of innovation within the sector. Emerging trends include smart technology integration for real-time monitoring and automation in industrial dust collection systems, which will enhance efficiency further while reducing operational costs. As industries increasingly prioritize worker safety and environmental responsibility, advancements in types of dust collectors will play a crucial role in shaping sustainable practices across all sectors.

Conclusion

In wrapping up our exploration of dust collection systems, it's clear that understanding the types of dust collectors and their applications is crucial for effective industrial operations. From bag house systems to portable collectors, each type has its unique advantages and best-fit scenarios. A well-chosen dust collector not only enhances air quality but also contributes to a safer work environment.

Key Takeaways on Dust Collector Types

When considering the various types of dust collectors, it’s essential to recognize that no one-size-fits-all solution exists. Bag houses excel in handling large volumes of dust, while cyclone collectors provide robust performance in specific settings. Portable dust collectors offer flexibility for smaller operations or projects requiring mobility, making them indispensable in certain industries.

Final Thoughts on Industrial Dust Collection

The importance of an efficient industrial dust collection system cannot be overstated; it directly impacts both productivity and employee health. As industries evolve, so too do the technologies behind these systems, with innovations enhancing both effectiveness and ease of use. Remember that investing in a high-quality air filter for dust not only meets regulatory standards but also fosters a culture of safety and responsibility within your organization.

The Importance of Choosing the Right System

Selecting the right industrial air purification system is pivotal for ensuring optimal performance and compliance with health regulations. Factors such as operational needs, space constraints, and budget considerations all play significant roles in this decision-making process. Ultimately, the right system will enhance your overall efficiency while safeguarding your workforce from harmful particulates.