Introduction

In the world of industrial operations, maintaining air quality is paramount, and that’s where dust collector types come into play. From Cyclone Dust Collectors to Electrostatic Precipitators, each system has its unique features designed to tackle airborne particles effectively. Understanding these dust collector types is essential for businesses looking to enhance their operational efficiency and ensure a safe working environment.

Understanding Dust Collector Types

Dust collectors are specialized systems that capture and filter out particulate matter from the air, making them indispensable in various industries. The primary dust collector types include Cyclone Dust Collectors, Cartridge Dust Collectors, Baghouse Dust Collectors, Wet Scrubbers, and Electrostatic Precipitators. Each type operates on distinct principles and offers specific advantages tailored to different applications.

Importance of Dust Collecting Systems

The significance of dust collecting systems cannot be overstated; they not only improve air quality but also protect equipment and enhance worker safety. Industrial dust collectors play a crucial role in minimizing health risks associated with airborne contaminants while ensuring compliance with environmental regulations. By investing in effective dust collection solutions, businesses can reduce downtime caused by maintenance issues related to excessive dust buildup.

Overview of Dust Collector Applications

Dust collectors find applications across a myriad of sectors including woodworking, metalworking, pharmaceuticals, and food processing industries. Each application demands a tailored approach—Cyclone Dust Collectors may excel in heavy-duty environments while Cartridge Dust Collectors are ideal for finer particulates. Understanding the specific needs of different industries helps in selecting the right type of dust collector for optimal performance.

What Are Dust Collectors?

Dust collectors are essential systems designed to capture and filter airborne particles generated during various industrial processes. These systems serve a dual purpose: protecting the health of workers by reducing exposure to harmful dust and enhancing the efficiency of operations by maintaining a clean environment. With various dust collector types available, including Cyclone Dust Collectors, Cartridge Dust Collectors, and Baghouse Dust Collectors, industries can choose the most suitable solution for their specific needs.

Definition and Purpose

At its core, a dust collector is a device that collects dust and other particulates from the air in an industrial setting. The primary purpose is to prevent these particles from escaping into the atmosphere, thereby ensuring compliance with health and safety regulations while improving air quality. By using different mechanisms—such as filtration or sedimentation—dust collectors effectively minimize airborne contaminants that can pose risks to both human health and machinery.

Common Industries Using Dust Collectors

Dust collectors find applications across a variety of industries where particulate matter generation is prevalent. Common sectors include woodworking, metal fabrication, pharmaceuticals, food processing, and mining—each benefiting from tailored solutions like Wet Scrubbers or Electrostatic Precipitators to handle specific types of dust emissions. In these environments, investing in efficient industrial dust collectors not only safeguards employee health but also enhances productivity by maintaining cleaner workspaces.

Benefits of Effective Dust Collection

The advantages of effective dust collection extend beyond mere compliance with regulations; they encompass improved worker safety, equipment longevity, and operational efficiency. By reducing airborne contaminants through systems like Baghouses or Cartridge Dust Collectors, companies can lower the risk of respiratory issues among employees while also minimizing maintenance costs associated with equipment wear and tear due to dust accumulation. Additionally, efficient dust collection contributes to better product quality by preventing contamination during manufacturing processes—a win-win for both businesses and their clients.

Cyclone Dust Collectors

Cyclone dust collectors are a popular choice among various dust collector types due to their efficient design and functionality. They utilize centrifugal force to separate dust and debris from the air, making them ideal for industrial environments where large volumes of particulate matter are generated. Understanding how these systems operate can help businesses choose the right solution for their specific needs.

How Cyclone Collectors Work

Cyclone dust collectors function by drawing in contaminated air through an inlet, which creates a spiraling airflow within a cylindrical chamber. The centrifugal force generated during this process causes heavier particles to be flung outward, collecting at the bottom of the unit while cleaner air exits through the top. This simple yet effective mechanism allows cyclone systems to handle larger particles efficiently, making them suitable for various industrial applications.

Pros and Cons of Cyclone Systems

One of the significant advantages of cyclone dust collectors is their low maintenance requirements compared to other types like cartridge or baghouse dust collectors. They can effectively manage larger particles without needing filters that require frequent replacement, resulting in cost savings over time. However, cyclone systems may not be as effective at capturing fine particles or fumes as other systems such as wet scrubbers or electrostatic precipitators, which could limit their application in certain industries.

Best Applications for Cyclone Dust Collectors

Cyclone dust collectors excel in environments where heavy particulate loads are present, making them ideal for industries such as woodworking, metalworking, and mining operations. Their robust design allows them to handle high volumes of airborne debris while maintaining efficiency and effectiveness in separating contaminants from clean air. While they may not replace more specialized dust collector types like baghouses or electrostatic precipitators entirely, they serve as excellent primary filtration units before further treatment is applied.

Cartridge Dust Collectors

Cartridge dust collectors are a popular choice among various industrial dust collector types. Known for their compact design and efficient filtration capabilities, these systems utilize cylindrical filter cartridges to capture airborne particles effectively. This makes them particularly suitable for environments where space is limited but dust control is still a priority.

Features of Cartridge Collectors

Cartridge collectors are designed with high-efficiency filters that provide superior dust capture rates, often exceeding 99% efficiency for fine particles. These systems typically feature a modular design, allowing for easy installation and maintenance—perfect for busy industrial settings. Additionally, most cartridge dust collectors come equipped with automatic cleaning mechanisms to ensure optimal performance without constant manual intervention.

Advantages in Industrial Settings

One of the standout advantages of cartridge dust collectors is their versatility across various applications, making them ideal for industries such as woodworking, metalworking, and pharmaceuticals. They can handle both dry and wet materials efficiently compared to other types like cyclone or baghouse dust collectors. Furthermore, their smaller footprint allows businesses to maximize floor space while maintaining effective air quality control.

Maintenance Best Practices

Maintaining cartridge dust collectors is key to ensuring long-term effectiveness and reliability in any industrial setting. Regularly inspecting filter cartridges for wear and tear can prevent costly downtime; replacing filters as needed will keep your system running smoothly. Additionally, implementing a scheduled cleaning routine will help maintain airflow efficiency and prolong the life of your equipment—making it an essential practice in managing industrial dust collectors.

Baghouse Dust Collectors

Baghouse dust collectors are a staple in many industrial environments, providing an efficient means of removing particulate matter from the air. These systems utilize a series of fabric filters or bags to capture dust particles as air passes through them, ensuring cleaner air and compliance with environmental regulations. The versatility and effectiveness of baghouses make them a popular choice among various dust collector types.

The Mechanics of Baghouses

At the heart of baghouse dust collectors lies a straightforward yet effective mechanism: dirty air enters the system, where it is funneled into a chamber containing multiple filter bags. As the air flows through these bags, larger particles are trapped on the surface while cleaner air exits the system. Over time, dust accumulates on the filters, necessitating periodic cleaning—a process often achieved via reverse airflow or mechanical shaking to dislodge collected particles.

Baghouses can be designed in different configurations based on specific needs, including pulse-jet systems that offer enhanced cleaning efficiency by using bursts of compressed air. This ensures that baghouse performance remains optimal while minimizing downtime for maintenance. Additionally, many baghouses come equipped with monitoring systems to track filter conditions and airflow rates, allowing for proactive management.

Comparing Baghouse Systems with Others

When comparing baghouse dust collectors to other options like cyclone dust collectors or cartridge dust collectors, several factors come into play—chiefly efficiency and application suitability. While cyclone systems excel at handling larger debris due to their mechanical separation method, they may not capture finer particles as effectively as baghouses can. On the other hand, cartridge dust collectors offer compact designs ideal for smaller spaces but may require more frequent filter replacements compared to traditional baghouses.

Moreover, wet scrubbers and electrostatic precipitators serve different purposes; wet scrubbers use liquid to capture pollutants while electrostatic precipitators rely on electrical charges for particle removal. Each system has its own advantages depending on specific industrial requirements and environmental regulations; however, when it comes to versatility across diverse applications, baghouses often take the lead among industrial dust collectors.

Top Industries Utilizing Baghouse Dust Collectors

Baghouse dust collectors find their niche across various industries requiring stringent air quality control measures. They are particularly prevalent in sectors such as cement production and metal fabrication where large volumes of fine particulate matter are generated during processes like grinding or welding. Additionally, pharmaceutical manufacturing relies heavily on baghouses for maintaining cleanroom standards by effectively capturing harmful substances before they can escape into the environment.

Moreover, industries involved in woodworking and food processing also benefit from using baghouses due to their ability to handle both dry and moist particulates efficiently—ensuring worker safety while adhering to health regulations. With advancements in technology continuously enhancing their capabilities, it's clear that baghouse systems will remain integral components within numerous sectors that prioritize effective pollution control.

Wet Scrubbers

Wet scrubbers are a unique solution in the realm of dust collector types, particularly when it comes to managing particulate matter and gaseous pollutants. Unlike their dry counterparts, such as cyclone dust collectors and baghouse dust collectors, wet scrubbers utilize a liquid medium—typically water—to capture contaminants from the air. This method not only enhances efficiency but also minimizes the risk of secondary pollution that can arise from other types of industrial dust collectors.

What Makes Wet Scrubbers Unique

What sets wet scrubbers apart from other dust collector types is their ability to handle both solid particles and vaporous pollutants simultaneously. They operate by introducing contaminated air into a chamber where it comes into contact with a scrubbing liquid, which absorbs or captures the unwanted materials. This dual-action capability makes wet scrubbers particularly effective in environments where moisture-laden or sticky particles are prevalent, making them indispensable in various industrial applications.

Applications of Wet Scrubber Technology

Wet scrubber technology finds its niche across multiple industries due to its versatility and effectiveness. Common applications include chemical processing plants, power generation facilities, and metal fabrication shops where emissions control is crucial for compliance with environmental regulations. In addition to mitigating harmful emissions, wet scrubbers can also be employed in food production facilities to maintain air quality while preventing contamination.

Environmental Benefits of Wet Scrubbers

One of the standout features of wet scrubbers is their significant environmental benefits compared to other dust collector types like electrostatic precipitators or cartridge dust collectors. By effectively removing harmful pollutants from exhaust gases before they enter the atmosphere, these systems play a vital role in reducing overall air pollution levels. Additionally, because they utilize water as a scrubbing agent, wet scrubbers can minimize waste by allowing for the recycling of captured materials back into production processes.

Electrostatic Precipitators

Electrostatic precipitators (ESPs) are a remarkable type of dust collection technology that employs electrical forces to capture particles from industrial emissions. Utilizing high-voltage electrostatic fields, these systems charge dust particles as they pass through, allowing them to be attracted to oppositely charged plates. This efficient mechanism sets electrostatic precipitators apart from traditional dust collector types, making them a popular choice in various industries.

Mechanism of Electrostatic Collectors

The operation of electrostatic collectors begins with the ionization of air molecules, which creates charged particles within the airflow. As dust-laden air enters the ESP, it passes through an ionization section where electrodes impart a negative charge to the particles. Once charged, these particles are drawn toward positively charged collection plates, leading to their removal from the gas stream and ultimately resulting in cleaner emissions.

Key Benefits Over Traditional Systems

One of the standout advantages of electrostatic precipitators over other industrial dust collectors is their ability to handle high volumes of air with minimal energy consumption. Unlike cyclone dust collectors or baghouse systems that may require significant maintenance and replacement parts due to filter clogging, ESPs operate continuously without frequent interruptions for cleaning or replacing filters. Moreover, they can efficiently capture very fine particulates that might escape other types like cartridge dust collectors or wet scrubbers.

Sectors That Benefit Most from Electrostatic Precipitators

Electrostatic precipitators find extensive application across several sectors that demand stringent emission controls and high efficiency in dust collection processes. Industries such as power generation, cement manufacturing, and metal processing heavily rely on ESPs for their ability to manage large quantities of particulate matter while minimizing operational costs. Additionally, sectors dealing with hazardous materials benefit significantly from this technology due to its effective filtration capabilities compared to traditional methods like baghouses or cyclone systems.

Conclusion

In the world of industrial operations, choosing the right dust collector type is crucial for maintaining a clean and safe environment. Each dust collector type—be it Cyclone dust collectors, Cartridge dust collectors, or Baghouse dust collectors—offers unique advantages tailored to specific applications. Understanding these differences ensures that businesses can optimize their processes while adhering to safety regulations.

Choosing the Right Dust Collector Type

When selecting a dust collector, it’s essential to consider factors such as particle size, airflow requirements, and operational environment. Cyclone dust collectors excel in handling larger particles and are often favored for their low maintenance needs. In contrast, Cartridge dust collectors are perfect for fine particulate matter and offer compact solutions ideal for space-constrained facilities.

Baghouse dust collectors stand out in industries where high volumes of particulates are generated; their extensive filtration capabilities make them a go-to choice for heavy-duty applications. Wet scrubbers provide an effective solution when dealing with sticky or hazardous materials, while electrostatic precipitators shine in sectors requiring ultra-fine particle removal without significant airflow resistance. Ultimately, understanding each option helps businesses select the most effective industrial dust collector suited to their needs.

Innovations in Dust Collecting Systems

The landscape of dust collection is evolving rapidly with technological advancements enhancing efficiency and effectiveness across various systems. New filtration materials and designs in Cyclone and Cartridge dust collectors improve capturing capabilities while reducing energy consumption significantly. Additionally, smart technologies integrated into Baghouse systems allow for real-time monitoring of performance metrics, enabling proactive maintenance strategies.

Wet scrubbers have also seen innovations that enhance their ability to handle corrosive substances safely while minimizing water usage—a win-win for both productivity and environmental sustainability. Meanwhile, electrostatic precipitators are benefiting from advancements in power supply technology that increase collection efficiency even further. These innovations not only improve operational performance but also contribute to cleaner air quality standards across industries.

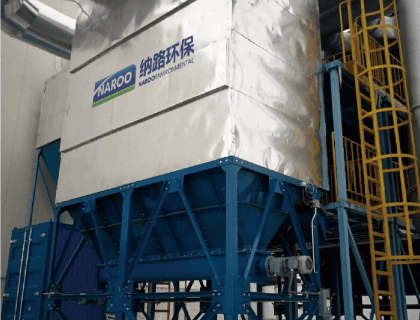

NAROO’s Role in Dust Collection Solutions

NAROO is at the forefront of providing comprehensive solutions tailored to meet diverse industrial needs regarding effective dust collection systems. With expertise spanning various types of industrial dust collectors—including Cyclone dust collectors and Baghouse systems—NAROO ensures clients receive customized recommendations based on specific operational challenges faced by different sectors.

Their commitment extends beyond just selling equipment; NAROO offers ongoing support through installation guidance and maintenance services that keep your systems running smoothly over time. By integrating cutting-edge technology with practical applications like Cartridge or Electrostatic precipitators into their offerings, NAROO plays a pivotal role in helping industries achieve optimal air quality standards while maximizing productivity.