Introduction

Understanding Baghouse Dust Collection Systems

Baghouse dust collection systems are sophisticated setups designed to capture and filter airborne particulates generated during manufacturing processes. These systems utilize fabric filter bags to trap dust particles, allowing clean air to be released back into the environment. Understanding how these systems operate is key for any facility dealing with aluminum dust, as effective management can significantly reduce risks associated with exposure.

Importance of Aluminum Dust Collectors

Aluminum dust collectors are particularly vital in industries where aluminum is machined or processed, as they help mitigate the hazards posed by fine metal particles that can ignite or cause respiratory issues. The importance of these collectors cannot be overstated; they not only enhance air quality but also contribute to compliance with stringent industry regulations regarding airborne contaminants. Investing in an efficient aluminum dust collector can lead to substantial long-term savings by minimizing waste and improving overall workplace safety.

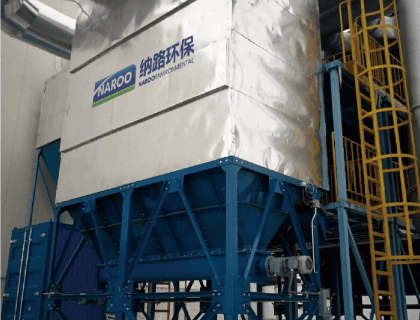

Role of NAROO in Dust Management

NAROO has established itself as a leader in providing innovative solutions for effective dust management, particularly when it comes to aluminum applications. Their expertise lies in designing tailored baghouse systems that address specific needs within various manufacturing environments while ensuring optimal performance and reliability. By partnering with NAROO, businesses can leverage cutting-edge technology and support services that make managing aluminum dust both efficient and sustainable.

How Baghouse Systems Work

Baghouse dust collection systems are the unsung heroes of industrial environments, especially in aluminum processing plants. They leverage advanced filtration technology to capture harmful dust particles, ensuring a cleaner and safer workspace for employees. Understanding how these systems operate is crucial for anyone involved in managing aluminum dust collectors.

Basics of Filtration Technology

At its core, filtration technology involves separating solid particles from air or gas streams using filter media, which is where baghouses shine. In an aluminum dust collector, specialized filter bags trap fine aluminum dust while allowing clean air to pass through, promoting better air quality. This process not only protects workers’ health but also helps maintain equipment efficiency by preventing dust buildup.

Key Components of a Baghouse

Every baghouse consists of several key components that work together seamlessly to ensure effective dust collection. The primary elements include the filter bags themselves, a clean air plenum for purified air discharge, and a fan or blower to create airflow through the system. Additionally, many aluminum dust collectors incorporate control systems that monitor pressure drops across the filters and automate cleaning cycles as needed.

Dust Collection Process Explained

The dust collection process begins when contaminated air enters the baghouse through an inlet ducting system designed to direct airflow efficiently. As the air passes through the filter bags within the aluminum dust collector, larger particles are captured on the surface while smaller ones penetrate deeper into the fabric material until they are completely trapped. Once sufficient buildup occurs on the bags, an automated cleaning mechanism dislodges trapped particles back into a hopper for disposal or recycling—ensuring continuous operation without interruption.

Benefits of Aluminum Dust Collectors

Enhanced Air Quality for Workers

One of the most compelling reasons to implement an aluminum dust collector is the immediate improvement in air quality for workers. By effectively filtering out harmful dust particles, these systems help create a cleaner and safer environment, reducing respiratory issues and other health risks associated with airborne contaminants. Moreover, enhanced air quality leads to increased worker satisfaction and productivity—because who wants to work in a dusty atmosphere?

Improved Compliance with Regulations

In today’s world, regulatory compliance is more crucial than ever, especially for industries dealing with hazardous materials like aluminum dust. Using an aluminum dust collector helps companies meet stringent environmental regulations by minimizing emissions and ensuring that pollutants are properly captured and disposed of. Failure to comply can result in hefty fines or even shutdowns, making it clear that investing in proper dust collection is not just smart—it's necessary.

Cost Savings Over Time

While the initial investment in an aluminum dust collector might seem significant, the long-term savings can be substantial. These systems reduce waste disposal costs by capturing reusable materials that would otherwise end up in landfills, allowing companies to reclaim valuable resources. Additionally, improved air quality can lead to fewer health-related absences among workers and reduced healthcare costs—a win-win situation if there ever was one!

Choosing the Right Dust Collector

Selecting the right aluminum dust collector for your facility is a crucial decision that can impact both your operations and worker safety. With a plethora of options available, it’s vital to understand the specific needs of your environment and how different systems perform under various conditions. This section will guide you through the key considerations to ensure you make an informed choice.

Factors to Consider

When choosing an aluminum dust collector, several factors should come into play. First and foremost, assess the type and volume of dust generated in your processes; this will dictate the capacity and filtration efficiency required from your system. Additionally, consider space constraints within your facility—some collectors require more room than others—and whether you need a portable unit or a fixed installation.

Another significant consideration is compliance with local regulations regarding air quality and workplace safety standards. An effective aluminum dust collector not only protects workers but also ensures that you meet legal requirements, avoiding potential fines or shutdowns. Lastly, think about maintenance requirements; systems that are easier to clean can save time and money in the long run.

Comparing Different Systems

Once you've identified your needs, it's time to compare different aluminum dust collectors on the market. Look at various filtration technologies—such as cartridge filters versus baghouse systems—and evaluate their performance metrics like airflow rates and filtration efficiency. It’s also essential to analyze energy consumption; some models may be more efficient than others, leading to significant cost savings over time.

Don’t forget about features such as automated cleaning systems or monitoring capabilities that can enhance operational efficiency. These innovations often mean less downtime for maintenance tasks while ensuring optimal performance during operation. Finally, gather feedback from other users in similar industries; their experiences can provide valuable insights into reliability and service support for each system.

NAROO's Innovative Solutions

NAROO stands out in the realm of aluminum dust collectors by offering innovative solutions tailored specifically for challenging environments like aluminum processing plants. Their advanced baghouse designs incorporate state-of-the-art filtration technology that maximizes efficiency while minimizing energy use—a win-win for both productivity and cost management!

Moreover, NAROO provides customizable options that allow facilities to adapt their dust collection systems based on specific operational needs without compromising on quality or compliance standards. Partnering with NAROO means gaining access not only to top-tier equipment but also expert support throughout installation and beyond—ensuring you have all the resources necessary for success.

Maintenance Best Practices

Maintaining your aluminum dust collector is crucial for ensuring optimal performance and longevity. Regular upkeep can prevent costly breakdowns and ensure compliance with health and safety regulations. In this section, we’ll discuss essential maintenance practices that keep your dust collection system running smoothly.

Regular Cleaning and Inspections

Regular cleaning of your aluminum dust collector is not just a good idea; it's essential for its efficiency. Dust buildup can obstruct airflow, reducing the system's effectiveness and potentially leading to hazardous conditions for workers. Schedule inspections at least quarterly to check filters, fans, and ductwork, ensuring everything is in tip-top shape.

During these inspections, pay special attention to the filter bags within the aluminum dust collector. If they show signs of wear or clogging, it may be time for replacement or cleaning—this will help maintain air quality in your facility while prolonging the life of your equipment. Remember, a well-maintained system is a happy system!

Troubleshooting Common Issues

Even the best aluminum dust collectors can experience hiccups from time to time; knowing how to troubleshoot common issues can save you valuable downtime. Start by checking for abnormal sounds or vibrations during operation; these could indicate mechanical issues that need addressing immediately. Additionally, if you notice a drop in suction power or an increase in visible dust emissions, it’s time to investigate further.

Another common issue involves filter performance—if you're experiencing frequent pressure drops or increased energy consumption, it may be due to clogged filters needing attention. Understanding these warning signs will empower you to take proactive measures before problems escalate into costly repairs or replacements of your aluminum dust collector systems.

Importance of Professional Support

While DIY maintenance can be effective up to a point, enlisting professional support ensures that every aspect of your aluminum dust collector gets the expert attention it deserves. Trained technicians have the knowledge and tools necessary to diagnose complex issues that might escape untrained eyes during routine checks. Plus, they can provide specialized cleaning services that enhance performance beyond what standard maintenance offers.

Partnering with professionals also means staying updated on industry best practices and innovations related to aluminum dust collection technology—an invaluable asset as regulations evolve over time! So don’t hesitate: invest in professional support when maintaining your systems for optimal efficiency and compliance.

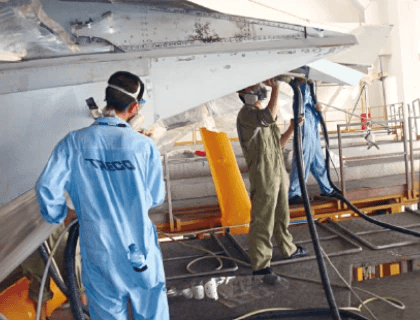

Case Studies in Aluminum Plants

The implementation of baghouse dust collectors in aluminum plants has proven to be a game-changer for many operations, enhancing both safety and efficiency. These case studies highlight how various facilities have successfully integrated aluminum dust collectors into their processes, leading to remarkable improvements. By examining real-world examples, we can glean insights into the effectiveness of these systems and the benefits they bring.

Successful Implementations of Baghouses

One notable case is a large aluminum manufacturing facility that faced severe challenges with airborne dust levels. After implementing a state-of-the-art aluminum dust collector, they reported a significant reduction in particulate matter in the air, leading to a healthier work environment for employees. The success of this installation not only improved air quality but also boosted morale among workers who felt safer on the job.

Another example comes from an aluminum recycling plant that struggled with compliance issues regarding environmental regulations. By investing in an advanced baghouse system specifically designed for aluminum dust collection, they were able to meet regulatory standards while simultaneously increasing their production output. This successful implementation demonstrates how targeted solutions can address specific industry challenges effectively.

Impact on Operational Efficiency

The impact of these baghouse systems extends beyond just compliance; operational efficiency sees a considerable boost as well. In one instance, an aluminum extrusion facility experienced reduced downtime due to fewer equipment malfunctions caused by accumulated dust buildup. With the new aluminum dust collector in place, maintenance needs decreased significantly, allowing workers to focus on production rather than cleanup.

Moreover, another plant noted that their energy consumption dropped after installing an efficient baghouse system tailored for aluminum dust collection. By optimizing airflow and reducing resistance within the system, they achieved not only cleaner air but also lower operational costs over time. Such enhancements illustrate how effective dust management can lead directly to improved bottom lines.

Lessons Learned from NAROO Projects

NAROO's involvement in various projects has provided valuable lessons for future implementations of aluminum dust collectors across the industry. One key takeaway is the importance of thorough site assessments before installation; understanding unique facility needs ensures optimal performance from day one. Additionally, ongoing training for staff about maintaining and operating these systems has proven crucial for long-term success.

Conclusion

In wrapping up our discussion on aluminum dust collectors, it becomes clear that the future of dust management in aluminum processing is both promising and essential. As industries continue to evolve, so too must the technology that supports them, ensuring cleaner environments and healthier workplaces. The advancements in baghouse systems are paving the way for more efficient operations and improved air quality, making them indispensable for modern facilities.

The Future of Aluminum Dust Collection

Looking ahead, the future of aluminum dust collection is bright, driven by innovation and a growing commitment to sustainability. With increasing regulations surrounding air quality and safety standards, manufacturers are compelled to adopt more sophisticated aluminum dust collectors that not only meet but exceed compliance requirements. This shift will likely lead to enhanced technologies such as smart monitoring systems that optimize performance while minimizing downtime.

Investing in Advanced Technology

Investing in advanced technology for aluminum dust collection is not merely a trend; it's a necessity for businesses aiming to thrive in a competitive market. Upgrading to state-of-the-art aluminum dust collectors can yield significant long-term savings through improved efficiency and reduced maintenance costs. Moreover, these investments contribute to better overall employee health and safety—an aspect no company can afford to overlook.

Partnering with NAROO for Success

When it comes to navigating the complexities of dust management, partnering with NAROO stands out as an advantageous strategy. NAROO’s innovative solutions in aluminum dust collectors ensure that businesses can achieve optimal performance while adhering to stringent regulations effortlessly. By collaborating with NAROO, companies not only enhance their operational efficiency but also position themselves as leaders in responsible manufacturing practices.