Introduction

In the world of industrial operations, dust collection systems are the unsung heroes, tirelessly working behind the scenes to maintain a clean and safe environment. Whether it’s a dust collector baghouse or a cartridge system, understanding these technologies is crucial for any business looking to enhance productivity and comply with regulations. Choosing the right dust collector can significantly impact efficiency, operational costs, and even employee health.

Understanding Dust Collection Systems

Dust collection systems play a vital role in managing airborne particles generated during various industrial processes. These systems capture dust before it can escape into the atmosphere, ensuring cleaner air and compliance with health standards. With options like baghouse and cartridge collectors available, businesses must grasp how each system operates to make informed decisions.

Key Differences Between Baghouse and Cartridge

When comparing baghouse dust collectors to cartridge systems, several key differences emerge that influence their suitability for specific applications. Baghouse systems utilize fabric filters that are effective at capturing larger quantities of fine particulate matter, while cartridge collectors often feature smaller filters optimized for higher airflow rates in compact spaces. Understanding these differences helps businesses choose the most effective collector dust solution tailored to their operational needs.

Why Choose the Right System Matters

Selecting the appropriate dust collection industrial system is not just about meeting regulatory requirements; it directly affects operational efficiency and maintenance costs as well. An ill-suited dust collector can lead to increased downtime due to frequent filter replacements or inefficient operation that drives up energy consumption. Ultimately, making an informed choice ensures long-term savings and contributes positively to environmental efforts.

What is a Baghouse Dust Collector?

Baghouse dust collectors are essential components in many industrial settings, designed to capture and filter out airborne particles and dust. These systems utilize a series of fabric filters, or bags, to trap dust while allowing clean air to pass through. The efficiency and effectiveness of a baghouse make it a popular choice for industries that generate significant amounts of particulate matter.

Overview of Baghouse Technology

At its core, the baghouse technology operates on the principle of filtration. Air laden with dust enters the baghouse unit, where it passes through multiple filter bags made from various materials designed to capture specific types of dust particles. The collected dust accumulates on the exterior of the bags until it's removed during a cleaning cycle, ensuring optimal performance for the industrial dust collector.

The construction and design of baghouses can vary significantly based on their intended use and application. Some models are equipped with pulse-jet cleaning mechanisms that use bursts of compressed air to dislodge accumulated dust without interrupting operation. This dynamic approach allows for continuous operation while maintaining high collection efficiency.

Applications of Baghouse Systems

Baghouse systems find their place in numerous industries where dust generation is prevalent, including manufacturing, woodworking, food processing, and pharmaceuticals. They are particularly effective in environments where fine particulates need to be controlled to maintain air quality standards and regulatory compliance. The versatility of these systems makes them suitable for various applications ranging from cement plants to metal fabrication facilities.

In addition to traditional manufacturing environments, baghouses are increasingly being used in recycling operations and waste management facilities to mitigate airborne contaminants effectively. Their ability to handle large volumes of dusty air makes them ideal for processes like grinding or mixing materials that produce significant amounts of particulate matter. As industries continue evolving towards sustainability practices, baghouses play an integral role in reducing emissions and protecting worker health.

Pros and Cons of Baghouse Collectors

When considering a baghouse as your choice for an industrial dust collector, it's essential to weigh both its advantages and disadvantages carefully. One major pro is their high collection efficiency; they can capture even very fine particles effectively when properly maintained with appropriate filter media—making them excellent at keeping workplaces clean from harmful dust exposure.

However, one notable con is that baghouses require regular maintenance due to their reliance on fabric filters which can become clogged over time if not managed correctly—this might lead some businesses toward other options like cartridge collectors instead. Additionally, depending on the design complexity or size needed for your application needs may lead you down a path requiring more space than anticipated within your facility layout.

In conclusion, choosing a dust collector like a baghouse involves understanding its operational mechanics alongside evaluating specific industry requirements while keeping costs associated with maintenance in mind—ultimately ensuring you select an option tailored best suited towards achieving optimal performance within your unique environment.

What is a Cartridge Dust Collector?

Cartridge dust collectors are specialized systems designed to efficiently capture and filter airborne particulates in various industrial settings. Unlike traditional dust collector baghouse systems, cartridge collectors utilize cylindrical filter cartridges that provide a compact and effective solution for managing dust. This technology has gained popularity due to its ability to deliver high filtration efficiency while minimizing the footprint required for installation.

Overview of Cartridge Technology

At the heart of cartridge dust collector technology lies a series of pleated filter cartridges, which significantly increase the surface area available for capturing dust particles. These filters are often made from materials that are engineered to trap fine particles while allowing clean air to pass through, ensuring optimal performance. The design enables easy replacement and maintenance, making it an attractive option for facilities seeking efficient dust collection without extensive downtime.

In contrast to a traditional baghouse system that relies on large fabric bags, cartridge systems can handle varying types of industrial dust with remarkable efficacy. Their modular design allows for scalability; as your operations grow or change, you can add or replace cartridges without major overhauls in your existing setup. This adaptability is one reason many industries prefer cartridge collectors when investing in their dust collection solutions.

Applications of Cartridge Systems

Cartridge dust collectors find applications across numerous industries where managing airborne particulate matter is crucial. From woodworking shops and metal fabrication facilities to pharmaceutical manufacturing plants, these collectors effectively address diverse types of industrial dust challenges. Their compact size makes them particularly suitable for environments where space is at a premium but efficient air quality management remains essential.

Moreover, they are well-suited for processes generating fine particulates such as grinding, sanding, or mixing operations—where traditional baghouse systems might struggle with efficiency due to their larger size and airflow requirements. Industries such as food processing also benefit from these systems because they can be equipped with filters specifically designed to meet stringent hygiene standards while still maintaining high filtration rates.

Pros and Cons of Cartridge Collectors

Like any industrial dust collector system, cartridge collectors come with their own set of advantages and disadvantages that should be carefully considered before making a choice between them and other options like baghouses. One significant advantage is their smaller footprint; this allows businesses with limited space the flexibility they need without sacrificing performance or efficiency in managing airborne contaminants.

However, there are some downsides worth noting as well—cartridge filters may require more frequent replacements than traditional baghouse filters depending on the type and volume of dust being collected. Additionally, while they excel at capturing fine particles, they might not perform as effectively when dealing with larger debris or heavier loads compared to a robust baghouse system designed specifically for those scenarios.

In summary, understanding both the strengths and limitations of cartridge collectors will help businesses make informed decisions about their specific needs regarding effective air quality management in industrial environments.

Performance Comparison: Dust Collector Efficacy

When it comes to dust collection systems, performance is paramount. The efficacy of a dust collector can significantly impact not only the cleanliness of an industrial environment but also operational efficiency and compliance with regulatory standards. In this section, we will examine how each system—baghouse and cartridge—handles dust, their effectiveness in industrial settings, and the associated maintenance and operational costs.

How Each System Handles Dust

The dust collector baghouse employs a series of fabric filters that capture airborne particles as they pass through the system. This design allows for high filtration efficiency, making it particularly adept at handling large volumes of fine particulate matter. On the other hand, cartridge dust collectors utilize cylindrical filters that provide a compact solution with a high surface area for effective dust capture.

Both systems excel in their own right; however, the baghouse often shines in applications where heavy dust loads are present. Its ability to handle larger quantities of collected material makes it ideal for industries such as mining or cement production. Conversely, cartridge collectors are better suited for environments where space is limited but still require robust filtration capabilities.

Ultimately, understanding how each system handles dust is crucial when choosing between a baghouse or cartridge collector dust solution. Efficiency in capturing airborne particles not only affects air quality but also influences long-term operational performance.

Effectiveness in Industrial Settings

In industrial settings, the choice between a baghouse or cartridge collector can be influenced by specific needs and conditions on-site. Baghouses are typically favored for their high capacity and durability when dealing with substantial amounts of industrial dust collection requirements. They perform exceptionally well under continuous operation conditions while maintaining low emissions levels.

Cartridge systems may be more effective in smaller operations or facilities that require quick installation and less space consumption. Their modular design allows for easy integration into existing setups without significant modifications to infrastructure. However, while they may offer convenience, their capacity limitations can sometimes hinder performance in larger-scale applications.

Evaluating effectiveness means considering both immediate needs and long-term goals within an industrial setting—whether it's maximizing output or minimizing downtime due to maintenance issues related to either type of collector dust solution.

Maintenance and Operational Costs

Maintenance plays an integral role in determining the overall cost-effectiveness of your chosen dust collection system. The baghouse requires periodic cleaning cycles to ensure optimal performance; while these can be labor-intensive depending on usage levels, they often result in lower replacement costs over time due to robust filter life expectancy compared to some alternatives like cartridge filters.

On the flip side, cartridge collectors tend to have higher filter replacement rates due to their smaller size and design constraints limiting dirt capacity before needing maintenance intervention or filter swapping out entirely. This leads many operators into considering long-term operational costs rather than just initial investments when selecting between these two types of systems.

Ultimately, assessing maintenance requirements alongside operational costs will help businesses make informed decisions about which type of industrial dust collector aligns best with both budgetary constraints and environmental goals.

Efficiency and Energy Consumption

When it comes to efficiency and energy consumption, the choice between a dust collector baghouse and a cartridge system can significantly impact your operational costs. Both systems serve the same primary purpose—collecting dust—but they do so in different ways that affect their energy requirements. Understanding these differences is crucial for any industrial setup aiming to optimize performance while minimizing expenses.

Energy Use of Baghouse vs. Cartridge

The energy use of a dust collector baghouse generally tends to be higher than that of cartridge systems, primarily due to the size and complexity of the equipment involved. Baghouses often require larger fans and more extensive ductwork, which can lead to increased energy consumption during operation. In contrast, cartridge collectors are designed with compactness in mind; they usually operate with lower airflow requirements, leading to reduced power usage without sacrificing efficiency.

However, it's important to consider that while the initial energy footprint of a baghouse may be larger, its longevity and capacity for handling high dust loads can offset these costs over time. An industrial dust collector baghouse can run efficiently for years if properly maintained, making it a worthwhile investment for facilities with heavy-duty dust collection needs. Ultimately, selecting between these two options will depend on your specific application requirements and long-term goals.

Life Cycle Costs of Dust Collection Systems

Life cycle costs encompass not just initial purchase prices but also ongoing operational expenses associated with maintenance, repairs, and energy consumption over time. While a dust collector filter for cartridge systems might have a lower upfront cost compared to a baghouse system, one must factor in the frequency of filter replacements and potential downtime due to maintenance issues. Baghouses often come equipped with robust filters designed for longer life spans under heavy use conditions; thus they may prove more economical in the long run despite their higher initial investment.

Moreover, understanding how each system integrates into your existing operations can also influence life cycle costs significantly. An efficient installation process means less disruption—saving both time and money—which is particularly relevant when considering industrial dust collection setups where productivity is key. By evaluating all associated costs over the lifespan of both types of collectors, you can make an informed decision that aligns with your budgetary constraints.

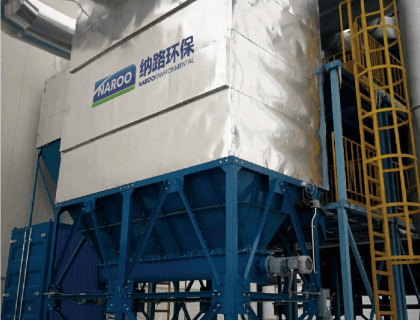

NAROO's Role in Energy-Efficient Solutions

NAROO has positioned itself as a leader in providing innovative solutions aimed at enhancing energy efficiency within dust collection systems. By developing advanced technologies tailored specifically for both baghouse and cartridge collectors, NAROO helps businesses reduce their overall environmental impact while maintaining compliance with regulatory standards related to emissions control. Their commitment goes beyond just selling equipment; NAROO actively engages in research aimed at optimizing designs that minimize power consumption without compromising performance.

For instance, NAROO’s latest offerings include intelligent monitoring systems that allow users to track performance metrics in real-time—ensuring optimal operation at all times while reducing unnecessary energy expenditure from poorly functioning units or filters needing replacement too soon. This proactive approach not only saves money but also contributes positively toward sustainable practices within industries reliant on effective dust collection solutions like mining or woodworking sectors where airborne particulates pose significant health risks.

Environmental Impact and Compliance

In today's industrial landscape, the importance of environmental compliance cannot be overstated. Dust collection systems, whether they are baghouse or cartridge types, play a crucial role in ensuring that workplaces adhere to regulatory standards designed to protect air quality. Understanding these standards is essential for businesses looking to implement effective dust collection solutions that minimize their environmental footprint.

Regulatory Standards for Dust Collection

Regulatory bodies have established stringent guidelines for dust emissions, particularly in industries where hazardous materials are processed. These standards dictate how much particulate matter can be released into the atmosphere, which directly impacts the choice of dust collector systems used. A reliable dust collector baghouse can often meet or exceed these regulations due to its superior filtration capabilities, making it a preferred option for many industrial applications.

Failure to comply with these regulations can lead to hefty fines and damage to a company's reputation. Therefore, investing in an efficient industrial dust collector not only ensures compliance but also promotes a safer working environment for employees. As companies strive to meet these regulatory demands, selecting the right collector dust system becomes paramount.

NAROO’s Innovations in Environmental Protection

NAROO is at the forefront of developing advanced technologies designed specifically for environmental protection within the realm of dust collection industrial processes. Their innovative designs focus on maximizing efficiency while minimizing energy consumption and emissions from both baghouse and cartridge systems. By integrating cutting-edge filtration technology into their dust collectors, NAROO sets new benchmarks for performance and sustainability.

One such innovation includes smart monitoring systems that provide real-time data on filter performance and air quality levels. This allows businesses to proactively manage their operations and ensure compliance with environmental regulations more effectively than ever before. NAROO’s commitment extends beyond just meeting standards; it aims at exceeding them through continuous improvement in their dust collector filter technologies.

Reducing Emissions with the Right Collector

Choosing the right type of dust collector is crucial when aiming to reduce emissions effectively within an industrial setting. Both baghouse and cartridge collectors have distinct advantages; however, understanding how each system operates can lead to better decision-making regarding emission control strategies. For instance, a properly maintained dust collector baghouse can significantly lower particulate emissions compared to less efficient options.

Moreover, regular maintenance of your chosen system—whether it’s a cartridge or baghouse—ensures optimal performance over time while reducing operational costs associated with emissions control equipment failures or inefficiencies. Investing in high-quality filters and components further enhances this ability by allowing your system to capture finer particles more efficiently than standard options available on the market today. Ultimately, selecting an appropriate collector not only meets compliance but also contributes positively towards global efforts aimed at cleaner air initiatives.

Conclusion

In the world of dust collection, making an informed choice is crucial for both efficiency and compliance. Whether you lean towards a dust collector baghouse or a cartridge system, understanding your unique needs will guide you to the right collector dust solution. Remember that the effectiveness of your industrial dust collector can significantly impact not only your operations but also the health and safety of your work environment.

Choosing the Right Dust Collector

Choosing the right dust collector involves evaluating factors such as airflow requirements, type of dust generated, and space constraints. A baghouse system is often favored for heavy-duty applications due to its robust filtration capabilities, while cartridge collectors shine in environments where space is at a premium or where fine particulates are prevalent. Ultimately, selecting between these systems requires careful consideration of both immediate needs and long-term operational costs associated with maintenance and filter replacements.

The Future of Dust Collection Technology

The future of dust collection technology is bright, with innovations aimed at improving efficiency and reducing environmental impact. Advancements in smart technology integration will allow for real-time monitoring of a dust collector's performance, ensuring optimal operation and timely maintenance alerts. As industries become more aware of their ecological footprint, we can expect to see more sustainable solutions that prioritize air quality alongside effective industrial dust collection.

NAROO's Commitment to Clean Air Solutions

NAROO stands at the forefront of clean air solutions, dedicated to developing cutting-edge technologies that enhance both performance and sustainability in dust collection systems. With a focus on energy-efficient designs, NAROO provides options that not only meet regulatory standards but also contribute positively to environmental protection efforts. By choosing NAROO’s innovative products, businesses can ensure they are investing in a cleaner future while effectively managing their dust challenges.