Introduction

Dust is often overlooked, yet it’s a constant companion in our daily lives, particularly in industrial settings. Understanding what you breathe is crucial, as dust particles can vary significantly in composition and source. From aluminum dust to metal dust from grinding processes, each type poses unique challenges and health risks that demand our attention.

Understanding Dust: What You Breathe

When we talk about dust, we're referring to tiny particles suspended in the air that can originate from various sources. Aluminum and steel dust reaction can produce hazardous compounds that may not be immediately apparent but have long-term implications for health and safety. Knowing the specific types of dust we encounter allows us to take proactive measures to mitigate their effects.

The Importance of Dust Removal Systems

Effective dust removal systems are essential in maintaining a safe working environment and ensuring compliance with health regulations. Industrial dust extractor filters play a pivotal role in capturing harmful particles before they become airborne hazards. Without proper systems like explosion proof dust collectors, industries risk increased exposure to dangerous substances that could lead to serious health issues.

Key Types of Dust in Industries

In industrial environments, several key types of dust are prevalent, including aluminum dust and metal dust generated from grinding operations. Each type requires specialized handling and extraction methods due to their unique properties and potential hazards during processes like cutting or welding. Understanding these distinctions is vital for choosing the right equipment, such as a suitable dust collector outside or an advanced aluminum dust extraction system tailored for specific needs.

What Is Dust?

Dust is more than just a nuisance that settles on surfaces; it's a complex mix of particles that can vary widely in composition and origin. Understanding what constitutes dust is crucial for developing effective dust management strategies, especially in industrial settings. From the microscopic to the macroscopic, dust plays a significant role in both our health and the environment.

Composition of Dust Particles

Dust particles are made up of an array of materials, including organic matter, minerals, and metals. In industrial environments, aluminum dust and metal dust from grinding processes are common components that can pose specific hazards. These particles often vary in size; smaller particles can remain airborne longer and penetrate deeper into the respiratory system.

Common Sources of Dust

Dust can originate from numerous sources, particularly in industrial settings where materials are processed or handled. Activities such as grinding, cutting, or sanding metals generate significant amounts of metal dust that can quickly accumulate if not properly managed. Additionally, construction sites and agricultural operations contribute to airborne dust levels that necessitate efficient dust collector outside solutions to mitigate exposure.

The Role of Aluminum Dust and Metal Dust

Aluminum dust presents unique challenges due to its reactive nature when mixed with other materials like steel dust; this aluminum and steel dust reaction can lead to hazardous situations if not controlled effectively. The need for specialized equipment such as explosion proof dust collectors becomes evident when dealing with these types of materials to ensure safety during processing. Furthermore, proper aluminium dust extraction systems are essential for minimizing health risks associated with inhalation and ensuring compliance with industry regulations.

Health Risks Associated with Dust

Dust might seem harmless, floating through the air like a lazy cloud, but its health risks are anything but trivial. In industrial settings, where aluminum and steel dust reaction can occur, the stakes are even higher. Understanding the potential respiratory issues and long-term effects of dust exposure is crucial for maintaining a healthy work environment.

Respiratory Issues from Dust Inhalation

Inhaling dust can lead to a variety of respiratory issues that range from mild irritation to chronic diseases. Workers exposed to metal dust from grinding or aluminum dust may experience symptoms such as coughing, wheezing, and shortness of breath. Over time, these symptoms can escalate into more severe conditions like pneumoconiosis or chronic obstructive pulmonary disease (COPD), highlighting the need for effective industrial dust extractor filters.

Long-Term Effects of Industrial Dust Exposure

The long-term effects of industrial dust exposure are alarming and often underestimated. Continuous inhalation of aluminum and steel dust can result in serious health complications that manifest years down the line. Studies have shown that prolonged exposure can lead to lung fibrosis, reduced lung function, and even an increased risk of lung cancer—making it imperative for industries to invest in robust explosion proof dust collectors.

Specific Risks of Aluminum and Steel Dust Reaction

The specific risks associated with aluminum and steel dust reaction cannot be ignored; they present unique challenges in industrial environments. When these metals come into contact with certain chemicals or heat sources, they can ignite or explode—creating hazardous conditions for workers who may already be vulnerable due to exposure to metal dust from grinding processes. Implementing proper safety measures alongside efficient aluminum dust extraction systems is essential for mitigating these risks.

Dust Collection Systems Explained

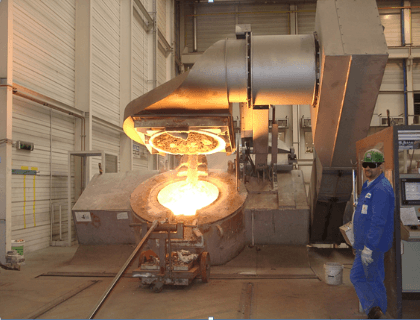

Dust collection systems are essential in industrial environments where dust generation is a constant challenge. The presence of aluminum and steel dust reaction can lead to serious safety hazards, making it crucial to implement effective dust management strategies. Industrial dust extractors play a pivotal role in maintaining air quality and ensuring the health of workers by capturing harmful particles before they become airborne.

Importance of Industrial Dust Extractors

Industrial dust extractors are designed to remove fine particles from the air, significantly reducing the risk associated with metal dust from grinding and other processes. These systems not only protect workers from respiratory issues but also help maintain equipment efficiency by preventing dust build-up. Investing in high-quality industrial dust extractor filters can enhance productivity while safeguarding employee health, making them a crucial component in any manufacturing setup.

How Explosion Proof Dust Collectors Work

Explosion proof dust collectors are engineered to handle combustible materials like aluminum and steel dust reaction safely. They feature specialized designs that contain potential explosions by using robust materials and advanced filtration systems that prevent ignition sources from coming into contact with flammable particles. By incorporating these safety measures, industries can mitigate risks associated with metal dust while ensuring compliance with safety regulations.

Choosing the Right Dust Collector Outside

Selecting the right dust collector outside requires careful consideration of various factors, including the type of operations being performed and the specific characteristics of aluminum dust or other material types involved. It's essential to evaluate whether a portable solution or a stationary unit best suits your needs based on space constraints and mobility requirements. Additionally, understanding local environmental regulations will guide you toward choosing an effective system that minimizes emissions while maximizing performance.

The Technology Behind Dust Extraction

In the world of industrial operations, effective dust extraction technology is crucial for maintaining a safe and productive environment. With various types of dust—especially aluminum and steel dust—being generated from processes like grinding, having the right systems in place is essential. This section will delve into industrial dust extractor filters, innovations in aluminum dust extraction, and how NAROO contributes to advanced solutions.

Overview of Industrial Dust Extractor Filters

Industrial dust extractor filters are the backbone of any effective dust collection system. These filters are designed to capture a wide range of particles, including fine metal dust from grinding operations and larger debris that can clog machinery or pose health risks. Selecting the right filter for an explosion proof dust collector is vital; it ensures that even the most hazardous particles from aluminum and steel do not escape into the workspace.

The efficiency of these filters can significantly impact overall air quality and worker safety. High-efficiency particulate air (HEPA) filters are often used in conjunction with other filtration technologies to maximize particle capture rates. By understanding the unique composition of metal dust—including aluminum and its reaction with other materials—manufacturers can create more effective filtration systems tailored for specific industries.

Innovations in Aluminum Dust Extraction

As industries evolve, so too do the technologies designed to handle their specific challenges, particularly when it comes to aluminum dust extraction. Recent innovations have focused on improving extraction efficiency while minimizing energy consumption, which is a win-win for both productivity and environmental sustainability. Advanced systems now incorporate smart technology that monitors air quality in real-time, allowing for adjustments based on current conditions.

One notable advancement involves specialized filter media that enhance capture rates for fine aluminum particles often released during machining processes. These innovations not only improve workplace safety by reducing exposure to harmful substances but also help companies comply with stringent environmental regulations surrounding metal dust emissions. Additionally, developments in mobile units allow for flexible placement of dust collectors outside work areas where high levels of aluminum or steel particles may accumulate.

NAROO’s Role in Advanced Dust Removal Solutions

NAROO has positioned itself as a leader in advanced solutions for industrial dust removal, particularly focusing on challenges associated with aluminum and steel applications. Their commitment to innovation has led them to develop cutting-edge explosion proof dust collectors specifically engineered to handle volatile materials safely without risk during processing or cleaning phases.

By integrating advanced filtration technology with robust design features tailored for demanding environments, NAROO ensures maximum efficiency while addressing potential hazards linked to metal dust from grinding operations or other manufacturing processes. Their products not only meet industry standards but also set new benchmarks for performance and reliability in the field of aluminium dust extraction.

As businesses increasingly recognize the importance of maintaining clean working environments free from harmful particulate matter, NAROO continues to lead advancements that prioritize both health safety and operational effectiveness.

Maintenance of Dust Removal Systems

Maintaining dust removal systems is crucial for ensuring safety and efficiency in industrial environments. Regular upkeep helps mitigate the risks associated with aluminum and steel dust reaction, which can pose significant hazards if not managed properly. A well-maintained system also extends the lifespan of equipment like industrial dust extractor filters, ultimately saving money in the long run.

Regular Checks for Dust Collectors

Regular checks for dust collectors are essential to ensure they function optimally. Inspecting the filters of your explosion proof dust collector routinely can prevent issues related to metal dust from grinding that might lead to hazardous conditions. Additionally, monitoring for clogs or wear in your aluminum dust extraction systems helps maintain airflow and efficiency, reducing the risk of a buildup that could cause an explosive reaction.

Common Issues and Troubleshooting Tips

Common issues with dust collection systems often stem from neglecting routine maintenance or failing to address minor problems before they escalate. For instance, if you notice a decrease in suction power, it could indicate clogged industrial dust extractor filters that need cleaning or replacement. If you experience frequent malfunctions with your dust collector outside, consider checking connections and seals to ensure no leaks are allowing aluminum and steel dust reaction to occur unchecked.

Best Practices for Maximizing Efficiency

To maximize efficiency in your dust removal systems, implementing best practices is key. Start by scheduling regular maintenance checks on your explosion proof dust collector and other equipment; this proactive approach will keep metal dust from grinding at bay while ensuring optimal performance during operations. Additionally, training employees on proper use and care of aluminum dust extraction tools can significantly reduce wear-and-tear while promoting a safer work environment overall.

Conclusion

In the world of industrial operations, effective dust management is not just a luxury—it's a necessity. By implementing robust dust collection systems, industries can significantly mitigate health risks associated with aluminum and steel dust reaction, while also enhancing workplace safety and productivity. An organized approach to dust control ultimately leads to healthier environments for workers and compliance with regulatory standards.

Benefits of Effective Dust Management

The benefits of effective dust management extend far beyond cleaner air; they encompass improved employee health, enhanced equipment longevity, and increased operational efficiency. Properly maintained industrial dust extractor filters capture harmful particles like metal dust from grinding before they can circulate in the air. Additionally, using an explosion proof dust collector minimizes the risk of fire or explosions caused by combustible aluminum dust, creating a safer work environment.

Moreover, companies that prioritize effective aluminum dust extraction often enjoy lower healthcare costs due to reduced respiratory issues among employees. This proactive approach fosters a culture of safety and responsibility that resonates throughout the organization. Ultimately, investing in advanced dust collection solutions pays dividends in both human health and operational performance.

The Future of Dust Control Technology

As technology advances, so too does the potential for innovative solutions in the realm of dust control. Future developments will likely focus on integrating smart sensors into industrial dust extractor filters to monitor particulate levels in real-time and optimize performance accordingly. These advancements will not only enhance efficiency but also allow for predictive maintenance, reducing downtime associated with common issues.

Moreover, as industries continue to explore sustainable practices, we can expect an increase in eco-friendly materials used in aluminum dust extraction systems and explosion proof designs that minimize environmental impact. The future is bright for those who embrace these technological changes; they stand to benefit from significantly improved safety protocols while staying ahead of regulatory demands.

Why You Should Consider NAROO Solutions

When it comes to choosing a reliable partner for your dust management needs, NAROO Solutions stands out as a leader in advanced technologies designed specifically for metalworking environments. Their expertise in aluminum and steel dust reaction prevention ensures that you receive tailored solutions that address your unique challenges effectively—be it through efficient industrial dust extractor filters or cutting-edge explosion proof designs.

NAROO’s commitment to quality means you’re investing not just in products but also in peace of mind knowing your workplace is safeguarded against hazards associated with metal dust from grinding activities or other processes involving hazardous materials like aluminum dust. With their extensive range of options—including versatile models suitable for outdoor applications—you can trust NAROO Solutions to provide the right fit for your operations.

In summary, effective management of industrial contaminants like aluminum and steel particulates is essential for any business aiming at sustainability and employee welfare. Embrace these innovations today; make NAROO Solutions your go-to ally for comprehensive solutions that ensure safe working conditions now—and into the future!