Introduction

In today’s industrial landscape, the importance of dust extraction systems cannot be overstated. These systems are essential in minimizing the harmful effects of aluminium dust and welding fumes, ensuring a safer working environment for employees. By investing in effective fume extraction equipment, companies can significantly enhance productivity while safeguarding their workforce.

Benefits of Dust Extraction Systems

Dust extraction systems are designed to capture and remove harmful particles from the air, including those generated during processes like welding aluminium to aluminium. By employing an efficient collector dust system, industries can reduce the risk of respiratory issues associated with prolonged exposure to harmful dust and fumes. Additionally, these systems contribute to a cleaner workspace, which not only promotes health but also reflects positively on a company's image.

Importance of Workforce Safety

Workforce safety is paramount in any industrial setting; after all, a safe worker is a productive worker. The presence of harmful substances such as aluminium dust can lead to serious health complications if not managed properly. Implementing robust fume extraction solutions is not just about compliance; it’s about creating an environment where employees feel valued and protected.

Link Between Clean Air and Productivity

The correlation between clean air and productivity is undeniable—when workers breathe easier, they work better! Poor air quality caused by accumulated welding fume can lead to distractions that slow down workflow and affect overall morale. By prioritizing effective dust control measures like aluminium dust extraction systems, companies can ensure their teams remain focused and engaged in their tasks.

The Role of Dust Extraction in Safety

In any workspace where aluminium is processed or welded, the presence of harmful dust cannot be overlooked. Proper aluminium dust extraction systems play a crucial role in maintaining a safe environment by minimizing exposure to hazardous particles. Without effective dust control measures, workers face significant health risks that can lead to serious long-term consequences.

Understanding Harmful Dust from Aluminium

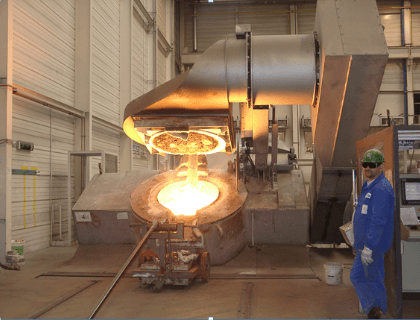

Aluminium dust is generated during various processes, including cutting, grinding, and welding aluminium to aluminium. This fine particulate matter can easily become airborne and pose serious health hazards if inhaled over time. Therefore, implementing robust aluminium dust extraction systems is essential to capture these particles before they circulate throughout the workplace.

The primary concern with aluminum dust is its potential to cause respiratory issues and other health problems among workers. Prolonged exposure can lead to conditions like asthma or even more severe pulmonary diseases. Thus, understanding the nature of harmful dust from aluminium highlights the need for effective collector dust strategies that ensure a cleaner and safer work environment.

Effects of Welding Fumes on Health

Welding fumes are another significant concern when it comes to worker safety in environments where welding occurs frequently. These fumes contain various toxic metals and gases that can adversely affect lung function and overall health if inhaled repeatedly over time. A well-designed welding fume extraction system is vital for mitigating these risks by effectively removing contaminants from the air.

Not only do welding fumes pose immediate health risks, but they can also contribute to chronic conditions if proper precautions are not taken. Workers exposed to high levels of these fumes may experience symptoms ranging from headaches and dizziness to more severe respiratory ailments later in life. Therefore, investing in quality fume extraction equipment becomes imperative for safeguarding employee well-being.

Importance of Fume Extraction Equipment

Fume extraction equipment serves as the frontline defense against harmful airborne pollutants generated during processes like welding and machining. Effective fume extraction systems ensure that both welding fumes and aluminium dust are captured at their source before they disperse into the working atmosphere. By utilizing advanced technology designed specifically for this purpose, businesses can create a healthier work environment while also enhancing productivity.

Moreover, proper fume extraction equipment not only protects workers but also contributes positively to overall operational efficiency by reducing downtime caused by illness or discomfort related to poor air quality. Investing in reliable dust control solutions is not just about compliance; it's about fostering a culture of safety within an organization that prioritizes its employees' health above all else. With NAROO’s commitment to providing top-notch solutions for fume extraction needs, companies can rest assured knowing they're making strides toward a safer workplace.

How Aluminium Dust Affects Productivity

The presence of aluminium dust in the workplace can be a significant obstacle to productivity, impacting everything from workflow efficiency to employee morale. When dust accumulates, it creates distractions that can divert focus from essential tasks. Therefore, effective aluminium dust extraction is not just a matter of cleanliness; it's integral to maintaining an efficient work environment.

Distractions Caused by Dust Accumulation

Aluminium dust can settle on surfaces and equipment, creating visual clutter that distracts workers and hampers their ability to concentrate. When employees must constantly deal with collector dust or wipe away residues from welding aluminium to aluminium processes, their attention is diverted from critical tasks. This distraction not only slows down production but also increases the likelihood of errors, which can be costly in terms of both time and resources.

Slowdowns in Workflow Due to Air Quality

Poor air quality resulting from insufficient fume extraction systems can lead to significant slowdowns in workflow. When workers are exposed to high levels of airborne contaminants like welding fumes, they may experience discomfort or health issues that force them to take breaks more frequently. Investing in a robust welding fume extraction system ensures cleaner air and helps maintain a steady workflow, allowing employees to stay focused and productive without unnecessary interruptions.

Negative Impact on Employee Morale

The accumulation of dust and poor air quality can have a detrimental effect on employee morale over time. Workers who feel uncomfortable or unsafe due to inadequate dust control measures are less likely to be engaged or motivated in their tasks. By prioritizing effective fume extraction equipment and establishing a clean work environment through proper aluminium dust extraction practices, companies can foster a positive atmosphere that boosts employee satisfaction and overall productivity.

Choosing the Right Dust Extraction System

Selecting the right dust extraction system is crucial for maintaining a safe and productive workplace, especially when dealing with aluminium dust and welding fumes. A well-designed system not only captures harmful particles but also contributes to overall operational efficiency. Understanding the features, criteria, and benefits of these systems can help businesses make informed decisions that prioritize both worker safety and productivity.

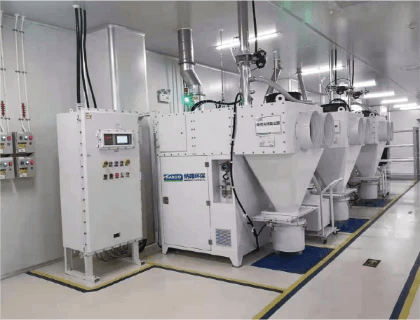

Features of Effective Dust Control Systems

Effective dust control systems are equipped with several key features that enhance their performance in managing aluminium dust extraction. High-efficiency particulate air (HEPA) filters are essential for capturing fine particles, ensuring that even the tiniest bits of debris are removed from the air. Additionally, a robust collector dust mechanism is necessary for minimizing build-up in work areas, reducing hazards associated with welding aluminium to aluminium processes.

Another important feature is adaptability; effective fume extraction equipment should be versatile enough to handle various types of operations without compromising performance. Systems designed with mobility in mind allow easy repositioning based on workflow changes or specific tasks, making them invaluable in dynamic work environments. Furthermore, noise reduction technology can significantly improve employee comfort by minimizing distractions caused by loud machinery during operation.

Criteria for Selecting a Welding Fume Extraction System

When it comes to selecting a welding fume extraction system, several criteria should be considered to ensure optimal performance and safety. First and foremost, look for systems specifically designed to handle welding fumes generated during processes like welding aluminium to aluminium; this ensures that they are equipped with appropriate filtration technologies tailored for such applications.

Next, assess the airflow capacity; an effective fume extraction system must provide adequate suction power to capture harmful fumes before they disperse into the workspace. Additionally, consider ease of maintenance—systems that allow quick filter changes or have self-cleaning capabilities will save time and reduce downtime in your operations.

Lastly, ensure compliance with local regulations regarding air quality standards; investing in equipment that meets or exceeds these requirements not only protects your workforce but also enhances your company's reputation as a responsible employer committed to health and safety.

Benefits of Investing in Quality Equipment from NAROO

Investing in quality equipment from NAROO offers numerous advantages when it comes to managing aluminium dust extraction effectively. NAROO's products are engineered with cutting-edge technology designed specifically for industrial applications involving hazardous materials like welding fumes and fine particulate matter generated during metalworking tasks. This commitment to quality means you can trust their systems will perform reliably under demanding conditions.

Moreover, NAROO’s focus on user-friendly designs ensures that employees can operate fume extraction equipment efficiently without extensive training or technical knowledge needed beforehand—this ultimately leads to higher productivity levels across your workforce. The durability of their products also means lower long-term costs due to reduced maintenance needs and fewer replacements over time.

Finally, partnering with NAROO aligns your business with an organization dedicated not just to profit but also environmental solutions—a win-win situation where improved workplace safety translates directly into enhanced employee morale and productivity levels.

Implementing a Dust Control Strategy

Creating an effective dust control strategy is essential for any workplace that deals with aluminium dust extraction and welding fumes. A well-structured plan not only safeguards the health of employees but also enhances overall productivity by maintaining a clean working environment. By focusing on key steps, training, and maintenance, businesses can ensure their dust extraction systems operate at peak efficiency.

Steps for an Effective Dust Extraction Plan

To kick off your dust extraction plan, begin with a thorough assessment of your workspace to identify areas where aluminium dust accumulation is likely to occur. This initial step will guide you in selecting the appropriate fume extraction equipment tailored to your specific needs, particularly in processes like welding aluminium to aluminium. Once you've pinpointed these areas, implement a systematic approach that includes installing collector dust systems strategically around the workspace to capture harmful particles before they become airborne.

Next, establish clear protocols for regular cleaning and monitoring of the dust control systems in place. This ensures that your fume extraction system remains functional and effective over time. Additionally, it’s wise to involve employees in this process; their insights can help refine the strategy further while fostering a culture of safety and accountability.

Finally, don't forget about compliance with health regulations regarding air quality standards—this is crucial for both legal reasons and employee well-being. Document each step taken in your aluminium dust extraction plan so you have records available for audits or inspections. With these steps firmly in place, you're well on your way to creating a safer work environment.

Employee Training on Dust Management

Training employees on proper dust management techniques is critical for maximizing the effectiveness of any fume extraction equipment installed in the workplace. Begin by educating staff about the dangers associated with aluminium dust and welding fumes—knowledge is power! When workers understand why they need to engage with these systems actively, they are more likely to take ownership of their roles in maintaining air quality.

Incorporate hands-on training sessions where employees can familiarize themselves with how to operate and maintain the welding fume extraction system effectively. Demonstrating how collector dust units function will empower them to recognize potential issues before they escalate into serious problems. Regular refresher courses should also be part of your training program; keeping knowledge fresh ensures that everyone remains vigilant against harmful airborne particles.

Furthermore, encourage open communication among team members about best practices related to dust control measures within their specific workstations. By fostering an environment where sharing tips and experiences is welcomed, you’ll create a collective commitment toward maintaining optimal air quality through effective management practices.

Regular Maintenance of Fume Extraction Systems

Regular maintenance of fume extraction systems is non-negotiable if you want them to perform optimally over time—think of it as giving your equipment a spa day! Schedule routine inspections and cleanings for all components involved in aluminium dust extraction processes so you can catch any issues early on before they lead to costly downtime or health hazards for employees working around welding fumes.

Be sure also to keep an eye on filters within your collector dust units; clogged filters can significantly reduce airflow efficiency and compromise air quality standards within the workspace. Establishing a maintenance log helps track when services were performed while ensuring no steps are overlooked during routine checks—after all, consistency is key!

Lastly, consider partnering with professionals who specialize in fume extraction equipment servicing if you're unsure about handling maintenance yourself or lack adequate resources internally. Their expertise will ensure everything runs smoothly while allowing you peace of mind knowing that safety remains top priority at all times!

Case Studies: Successful Dust Extraction Implementation

In the quest for cleaner air and improved productivity, numerous industries have successfully implemented dust extraction systems tailored to their specific needs. These case studies illustrate how effective aluminium dust extraction and fume extraction equipment can lead to significant gains in both safety and efficiency. By examining real-world examples, we can see that investing in quality dust control solutions pays off in more ways than one.

Real-World Examples of Productivity Gains

One notable example comes from an automotive manufacturing facility that specializes in welding aluminium to aluminium components. Before installing a dedicated welding fume extraction system, workers faced constant interruptions due to excessive dust accumulation, which not only hampered visibility but also slowed down workflow significantly. After implementing an advanced collector dust system, the facility reported a 30% increase in production rates as distractions decreased and air quality improved.

Another case involves a fabrication shop that struggled with harmful aluminium dust from its operations. By investing in a comprehensive dust extraction strategy that included both local exhaust ventilation and portable fume extraction units, the company saw a marked improvement in employee output and satisfaction levels. Workers could now focus on their tasks without the nagging concern of inhaling hazardous particles, leading to fewer sick days and enhanced morale.

Finally, an aerospace manufacturer adopted a robust fume extraction equipment setup designed specifically for high-volume welding operations. The results were nothing short of remarkable: not only did they comply with stringent safety regulations, but they also experienced a 25% reduction in rework due to cleaner working conditions. This success story highlights how effective dust control can transform operational efficiency while ensuring worker health.

Testimonials from Industries Using NAROO Solutions

Many businesses have turned to NAROO for their aluminium dust extraction needs, praising the effectiveness of their innovative solutions. One satisfied client from the metalworking industry stated that the difference was immediate; our new welding fume extraction system not only cleared the air but also boosted our productivity. With reduced downtime caused by poor air quality, employees felt more energized and engaged throughout their shifts.

Another testimonial comes from a construction firm specializing in metal fabrication who noted that NAROO's collector dust systems have revolutionized our approach to workplace safety. They highlighted how easy it was to integrate these systems into existing workflows while maintaining compliance with health regulations—an essential factor for any business operating today.

Lastly, an electronics manufacturer shared their experience with NAROO's fume extraction equipment by stating that the investment has paid off tenfold; we’ve seen improvements across all metrics. From increased worker satisfaction to enhanced overall productivity levels, this company exemplifies how adopting effective dust control measures can lead to long-term benefits.

Long-term Benefits of Dust Control in the Workplace

Implementing efficient aluminium dust extraction systems yields long-term benefits extending beyond immediate productivity gains. One significant advantage is improved employee health; less exposure to harmful particles translates into lower healthcare costs and fewer work-related illnesses over time. Companies committed to maintaining clean work environments often enjoy higher retention rates as employees appreciate being part of organizations prioritizing safety.

Moreover, businesses utilizing proper welding fume extraction systems generally report enhanced compliance with environmental regulations over time as well—a crucial aspect for staying competitive within today's market landscape. By investing upfront in quality fume extraction equipment like those offered by NAROO, companies safeguard themselves against potential fines or penalties associated with inadequate workplace safety measures.

Ultimately, embracing comprehensive dust control strategies fosters a culture of responsibility within organizations—one where employee well-being is paramount alongside operational efficiency. As these case studies demonstrate, integrating robust aluminium dust management practices not only protects workers but also propels businesses toward sustainable growth and success.

Conclusion

As we wrap up our discussion on the importance of dust extraction systems, it’s clear that these systems play a pivotal role in enhancing worker safety and improving overall productivity. By effectively managing harmful aluminium dust and welding fumes, businesses can create a healthier work environment that prioritizes employee well-being. This not only helps in compliance with safety regulations but also fosters a culture of care and responsibility.

Enhancing Worker Safety with Dust Extraction

Worker safety is significantly bolstered by effective dust extraction solutions, particularly in environments where aluminium dust poses health risks. Implementing an efficient fume extraction system ensures that harmful particles are captured before they can affect employees' respiratory health. With proper dust control measures, companies demonstrate their commitment to protecting their workforce from the dangers associated with welding aluminium to aluminium.

Boosting Productivity Through Clean Air

Clean air is synonymous with enhanced productivity; when employees breathe easier, they work better. Dust accumulation can lead to distractions and workflow slowdowns, ultimately affecting morale and output levels. By investing in quality fume extraction equipment, businesses can ensure that their teams remain focused and engaged, leading to increased efficiency across operations.

NAROO’s Commitment to Environmental Solutions

NAROO stands at the forefront of providing innovative solutions for aluminium dust extraction and fume management. Their dedication to producing high-quality collector dust systems reflects a commitment not just to workplace safety but also to environmental sustainability. By choosing NAROO's advanced welding fume extraction systems, companies are not only investing in their workers’ health but are also contributing positively to the planet.