Introduction

In the realm of industrial operations and woodworking, dust collectors play a pivotal role in maintaining a clean and safe environment. These machines are designed to capture airborne particles, ensuring that workplaces remain not only tidy but also compliant with health regulations. Understanding how do dust collectors work is essential for anyone interested in optimizing their dust collection system.

Understanding Dust Collectors

Dust collectors are specialized systems that employ various technologies to filter out dust and other particulate matter from the air. At their core, these systems consist of a fan, filter, and collection container—each playing a crucial role in the overall functionality of the dust collector machine. By utilizing mechanisms like cyclone separators or bag filters, these devices efficiently remove contaminants from the air stream.

Importance of Effective Dust Collection

Effective dust collection is vital for several reasons: it enhances air quality, improves worker safety, and protects equipment from damage caused by accumulated debris. In industries such as woodworking or metalworking, where fine particles can pose serious health risks, having a reliable dust collection system is non-negotiable. Moreover, an efficient cyclone dust collector not only reduces airborne pollutants but also minimizes cleaning time and costs associated with maintaining a clean workspace.

Overview of Dust Collection Systems

Dust collection systems come in various shapes and sizes tailored to different applications—from portable units suitable for small workshops to large-scale centralized systems used in manufacturing plants. The choice between them often hinges on factors like workspace size, type of materials being processed, and specific industry requirements. Whether you're considering a compact dust collector for your wood shop or an industrial-grade cyclone separator for heavy-duty tasks, understanding your options will help you make an informed decision.

How Do Dust Collectors Work?

Dust collectors are essential tools that keep our workspaces clean and safe by removing airborne particles generated during various industrial processes. But how do dust collectors work? At their core, these systems utilize a combination of physical principles and mechanical components to efficiently capture dust, ensuring that workplaces remain free from harmful pollutants.

The Mechanics Behind Dust Collection

The mechanics behind dust collection involve the principles of airflow and filtration. A dust collection system creates a vacuum effect that draws in air laden with dust particles through a series of ducts connected to machinery or work areas. Once the air enters the dust collector, it is directed toward filters or separators that trap the particles while allowing clean air to be released back into the environment.

Understanding how do dust collectors work requires familiarity with airflow dynamics, which dictate how effectively a system can capture different sizes of particles. Larger particles tend to settle quickly due to gravity, while smaller ones remain suspended in the air longer, making them more challenging to filter out. This is where specialized components like cyclone separators come into play, enhancing overall efficiency.

Key Components of a Dust Collector

A dust collector typically comprises several key components that work together seamlessly for optimal performance. The primary elements include an intake hood or ducting system that captures airborne particles, a filtration system where contaminants are collected, and a fan or blower that generates airflow throughout the entire setup. In many cases, additional features like cyclone separators are integrated to improve particle separation before reaching the filters.

The effectiveness of any dust collection system hinges on these components working harmoniously; if one part falters, it can compromise the whole operation. For instance, if the filters become clogged or damaged over time—common in heavy-use settings—the efficiency drops significantly as airflow is restricted and more pollutants escape back into the workspace. Regular maintenance is crucial for keeping each component in top shape.

Types of Dust Collection Systems

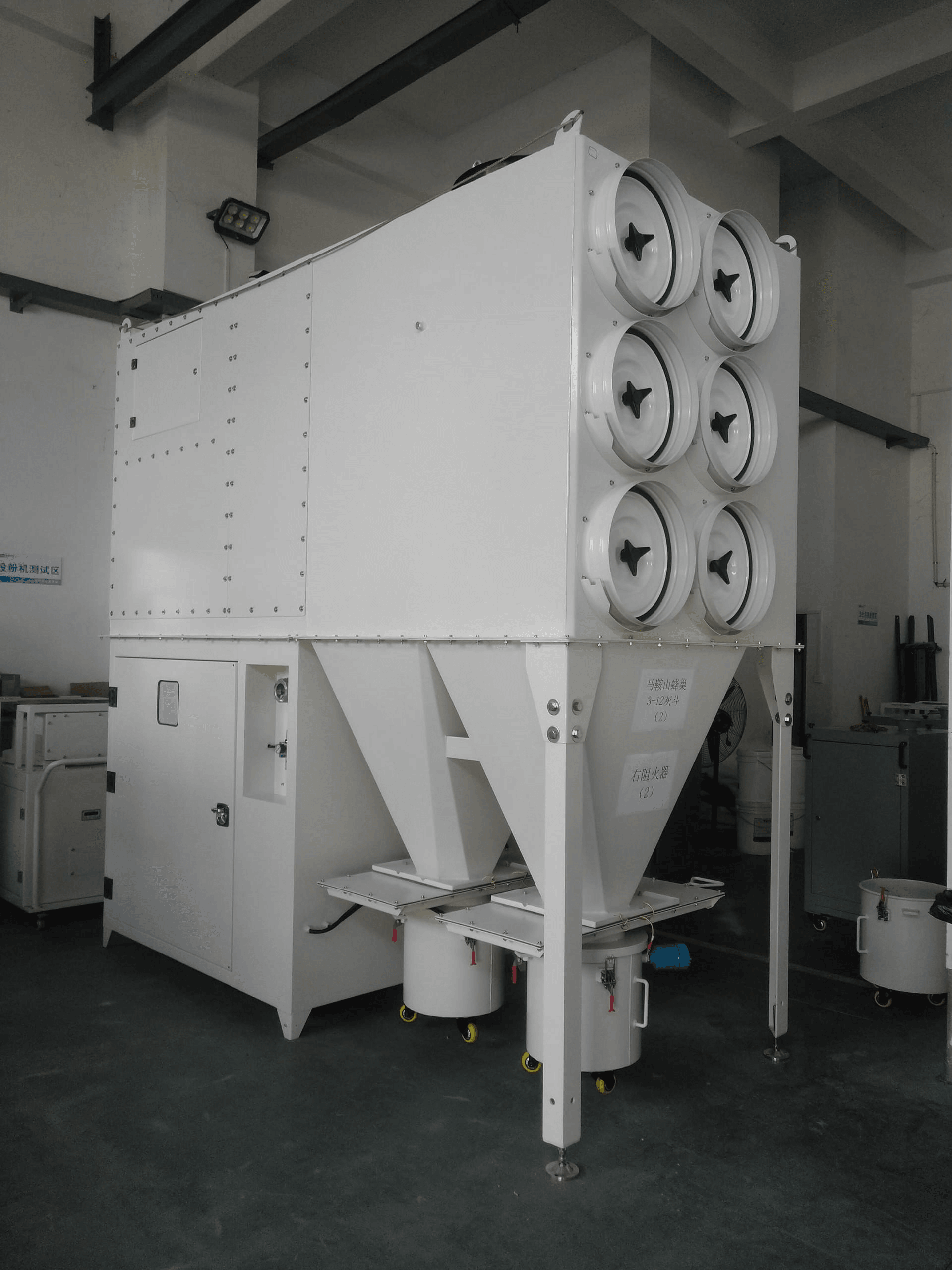

When exploring different types of dust collection systems available on the market today, you’ll find several variations tailored for specific applications and industries. From portable units designed for small workshops—often referred to as dust collector machines—to larger stationary setups used in manufacturing plants, there’s something for every need. One popular option among woodworkers is a dedicated dust collection system for wood shops equipped with features aimed at managing fine sawdust effectively.

Among these systems are baghouse collectors and cartridge collectors; both utilize unique methods for filtering out particulates but cater to different operational requirements based on factors such as particle size and volume produced during processes like sanding or cutting wood. Cyclone dust collectors stand out due to their ability to handle larger debris before it even reaches finer filtration stages—making them ideal for heavy-duty applications where large amounts of material may clog traditional filters quickly.

In summary, understanding how do dust collectors work begins with recognizing their mechanics and key components while also appreciating the variety of systems available tailored specifically for different environments—from small home workshops to expansive industrial facilities focused on maintaining clean air quality standards.

The Role of Cyclone Separators

Cyclone separators are a crucial component in many dust collection systems, particularly for those seeking efficient and effective dust management solutions. By harnessing the power of centrifugal force, these devices can separate dust and debris from the air stream without the need for complex filters. Understanding how do dust collectors work, especially with cyclone technology, can significantly improve your dust collection efficiency.

How Cyclone Separators Operate

Cyclone separators operate on a simple yet effective principle: they create a vortex that spins incoming air and particles around a cylindrical chamber. As the air moves in this circular motion, heavier particles are flung outwards due to centrifugal force and collected at the bottom of the cyclone separator. This process effectively removes larger debris from the airflow before it reaches the dust collector machine, ensuring cleaner air is sent through subsequent filtration stages.

The design of cyclone separators can vary based on specific needs but generally includes an inlet for dirty air, a conical section for particle separation, and an outlet for clean air. This straightforward mechanism makes cyclone dust collectors an excellent choice for various applications where heavy loads of particulate matter are present. As part of a comprehensive dust collection system, they play an essential role in maintaining optimal performance.

Advantages of Cyclone Dust Collectors

One significant advantage of using cyclone dust collectors is their ability to handle large volumes of particulate matter without clogging or requiring frequent maintenance. Unlike traditional filter-based systems that may become overwhelmed quickly, cyclone separators excel in high-load situations by efficiently separating larger particles before they enter more sensitive filtration stages. This not only prolongs the life of your filters but also enhances overall system efficiency.

Another benefit is their versatility; cyclone separators can be integrated into various types of dust collection systems tailored to different industries—from woodworking shops to metal fabrication facilities. Their robust construction allows them to handle abrasive materials without compromising performance or durability. Furthermore, with fewer moving parts compared to traditional systems, maintenance requirements are significantly reduced.

Applications in Various Industries

Cyclone separators find applications across numerous industries thanks to their effectiveness in managing particulate matter efficiently. In woodworking shops specifically—where sawdust and wood shavings abound—a well-designed dust collection system featuring a cyclone separator ensures that airborne particles are effectively captured before they accumulate on surfaces or enter workers' lungs.

In addition to woodworking applications, these devices are also widely used in metalworking industries where fine metal shavings pose both safety hazards and operational challenges if left unchecked. The food processing industry benefits as well; here, maintaining cleanliness is paramount while managing flour or grain particulates effectively through specialized cyclone systems designed for hygienic operation.

Dust Collection Systems for Wood Shops

Dust collection systems are essential in woodworking environments, where sawdust and debris can accumulate rapidly. Without an effective dust collector, not only can air quality diminish, but the risk of fire hazards and respiratory issues also increases. Understanding how do dust collectors work is crucial for woodworkers aiming to maintain a clean and safe workspace.

Importance of Dust Control in Woodworking

In woodworking, managing dust is not just about cleanliness; it’s vital for health and safety. Fine particles from wood can lead to serious respiratory problems if inhaled over time, making a reliable dust collection system indispensable. Moreover, excessive dust can interfere with machinery performance and even pose a fire risk—so investing in a quality dust collector is key.

Features of an Effective Wood Shop Dust Collector

An effective dust collector machine should possess several critical features to ensure optimal performance. First, look for a cyclone separator design that efficiently separates larger particles from fine dust before they reach the filter system. Additionally, features like variable speed controls and easy-to-empty containers enhance usability while ensuring that your dust collection system remains efficient and easy to maintain.

Tips for Choosing the Right System

When selecting a dust collection system for your wood shop, consider the size of your workspace and the types of machines you will be using. A cyclone dust collector might be ideal for larger setups due to its superior efficiency in handling heavy loads of sawdust. Finally, always check reviews and case studies on specific models—this way you’ll know exactly how do dust collectors work in real-world scenarios before making your purchase.

Exploring Dust Collector Machines

When it comes to maintaining a clean and safe workspace, understanding the different types of dust collector machines is essential. These machines play a crucial role in various industries, from woodworking to manufacturing, by effectively managing airborne particles. Knowing how do dust collectors work can help you choose the right system for your specific needs.

Common Types and Their Uses

There are several common types of dust collectors, each designed for specific applications. The most popular include baghouse collectors, cartridge collectors, and cyclone dust collectors. Baghouse systems are ideal for large-scale operations where fine particulate matter is prevalent, while cartridge collectors excel in environments with limited space yet high filtration needs; both effectively utilize a dust collector separator to improve air quality.

Cyclone separators stand out as an efficient option for handling larger particles before they reach the main filtration system. This pre-separation minimizes wear on filters and extends their lifespan—making it a smart choice for industries like woodworking where sawdust is abundant. Understanding these common types allows businesses to select the best dust collection system that aligns with their operational requirements.

Innovations in Dust Collector Technology

The world of dust collection technology has seen remarkable innovations over recent years, making systems more efficient and user-friendly than ever before. For instance, modern cyclone separators have been enhanced with advanced airflow dynamics that increase separation efficiency while reducing energy consumption—a win-win for both performance and sustainability! Additionally, smart technology integration allows users to monitor filter conditions and airflow remotely.

Another exciting development is the introduction of self-cleaning capabilities in many dust collector machines. These features not only reduce maintenance time but also ensure consistent performance without manual intervention—perfect for busy industrial environments where downtime can be costly. As innovations continue to emerge, we can expect even more effective solutions that enhance how do dust collectors work across various sectors.

Maintenance and Care for Longevity

To ensure your dust collection system operates at peak efficiency over its lifespan, regular maintenance is key. This includes routine inspections of filters and components within your cyclone dust collector or any other type of machine you may have installed in your wood shop or factory setting. Keeping an eye on potential wear-and-tear will help prevent larger issues down the line.

Another important aspect of maintenance involves cleaning out accumulated debris from the dust collector separator regularly; this helps maintain optimal airflow and prevents clogs that could hinder performance. It's also wise to follow manufacturer recommendations regarding replacement schedules for filters—after all, a well-maintained system not only works better but also lasts longer! By prioritizing care for your equipment, you'll maximize its efficiency while ensuring a healthier work environment.

NAROO’s Impact on Dust Collection

When it comes to dust collection systems, NAROO has been a game changer. Their innovative approach integrates advanced technology with practical applications, ensuring that dust collectors not only function effectively but also enhance the overall efficiency of industrial processes. By focusing on both performance and user experience, NAROO's dust collector machines have set new standards in the industry.

NAROO's Innovations in Dust Collection Systems

NAROO has pioneered several cutting-edge designs that redefine how dust collectors work. One notable innovation is their cyclone separator technology, which significantly improves the efficiency of dust collection systems by separating larger particles before they reach the main filter. This means longer filter life and reduced maintenance costs for users who rely on effective dust control in their operations.

Moreover, NAROO's commitment to creating compact and versatile cyclone dust collectors allows them to fit seamlessly into various work environments, from wood shops to manufacturing plants. These systems are designed with user-friendly features such as easy access for cleaning and maintenance, ensuring that operators can keep their equipment running smoothly without hassle. By constantly evolving their product line, NAROO ensures that customers receive state-of-the-art solutions tailored to meet their specific needs.

Commitment to Environmental Sustainability

In today’s world, environmental sustainability is more crucial than ever—and NAROO takes this responsibility seriously. Their dust collection systems are engineered not only for high performance but also with eco-friendly practices in mind. By optimizing air filtration and minimizing energy consumption, NAROO helps industries reduce their carbon footprint while maintaining compliance with stringent environmental regulations.

Furthermore, many of their cyclone separators are designed to capture fine particulates that could otherwise escape into the atmosphere or contribute to workplace pollution. This commitment extends beyond product design; it encompasses a holistic approach where sustainable practices are integrated into every aspect of production and operation at NAROO facilities. With such dedication to preserving our planet while providing effective solutions for businesses, it's clear that NAROO stands out as a leader in environmentally responsible manufacturing.

Case Studies of NAROO Solutions in Action

To illustrate the impact of NAROO's innovations in real-world applications, consider a woodworking shop struggling with excessive sawdust accumulation—a common challenge faced by many woodworkers today. After implementing a customized dust collection system for wood shop operations featuring advanced cyclone separators from NAROO, they reported a dramatic improvement in air quality and employee satisfaction due to reduced respiratory issues linked to airborne particles.

Another success story comes from an automotive parts manufacturer that faced challenges managing metal shavings generated during machining processes. By integrating a specialized dust collector machine equipped with high-efficiency filters and robust cyclone technology from NAROO, they achieved significant reductions in downtime related to cleaning and maintenance while enhancing overall productivity levels across the facility.

These case studies exemplify how effective implementation of innovative dust collection systems can transform workplaces across various industries—demonstrating not just improved operational efficiency but also contributing positively towards employee health and environmental stewardship.

Conclusion

Dust collection is not just a luxury but a necessity in various industries, playing a crucial role in maintaining air quality and ensuring worker safety. An effective dust collection system minimizes health risks associated with airborne particles, enhances operational efficiency, and helps comply with regulatory standards. As we’ve explored throughout this discussion, understanding how do dust collectors work is fundamental to selecting the right system for your specific needs.

The Importance of Dust Collection in Industry

In industries ranging from woodworking to manufacturing, the significance of a robust dust collector cannot be overstated. Dust particles can lead to respiratory problems and pose fire hazards; thus, implementing an efficient dust collection system is vital for safeguarding both employees and equipment. Moreover, investing in solutions like cyclone separators can enhance productivity by keeping workspaces cleaner and more organized.

Choosing the Right Dust Collector for Your Needs

Considerations such as the type of materials being processed and the size of your workspace will guide you toward choosing between options like cyclone dust collectors or traditional bag filters. Additionally, understanding how do dust collectors work will empower you to make informed decisions about maintenance and performance optimization.

Future Trends in Dust Collection Technology

The future of dust collection technology looks promising as innovations continue to emerge aimed at improving efficiency and sustainability. Expect advancements such as smart monitoring systems that provide real-time data on performance metrics for your dust collector separator or enhancements in filtration materials that capture even smaller particles effectively. With environmental concerns rising, integrating eco-friendly practices into your dust collection system for wood shops will not only benefit the planet but also position businesses as leaders in responsible manufacturing.