Introduction

In an era where clean air is becoming increasingly vital, the baghouse dust collector stands out as a hero in industrial air purification. This essential equipment not only captures harmful particulates but also plays a crucial role in enhancing workplace safety and environmental compliance. Understanding what a baghouse dust collector is and its working principle can empower industries to make informed decisions about their air quality management strategies.

Understanding the Baghouse Dust Collector

So, what is a baghouse dust collector? It’s essentially a filtration system designed to remove particulate pollutants from industrial exhaust streams, utilizing fabric filter bags to trap dust while allowing clean air to pass through. The baghouse operates on the principle of surface filtration, making it highly effective for various applications across different industries. With its robust design and efficiency, it has become a popular choice compared to alternatives like cyclone dust collectors.

The Need for Enhanced Air Quality

The need for enhanced air quality cannot be overstated, especially in today’s industrial landscape where regulations are tightening and public health concerns are rising. Factories and manufacturing plants produce significant amounts of airborne pollutants that can harm both workers and the environment if left unchecked. By implementing systems such as a baghouse dust collector, businesses can significantly reduce their emissions, contributing not just to compliance with environmental standards but also fostering healthier workspaces.

Key Components of a Baghouse Dust Collector

Understanding the key components of a baghouse dust collector is crucial for anyone looking to improve their facility's air quality management practices. At its core, this system includes filter bags made from specialized materials designed to capture fine particles effectively while maintaining airflow efficiency. Additionally, features like cleaning mechanisms and hoppers for collecting filtered material play vital roles in ensuring the longevity and effectiveness of these systems—key considerations when deciding whether a baghouse or cartridge system would better suit your needs.

What is a Baghouse Dust Collector?

Definition and Functionality

At its core, a baghouse dust collector consists of several fabric filter bags that trap dust and other particulates as air passes through them. The working principle hinges on the concept of filtration—where dirty air enters the system, flows through these bags, and emerges cleaner on the other side. Not only does this process effectively remove particulate pollutants, but it also enhances overall air quality in work environments.

Common Applications in Industries

Baghouse dust collectors are versatile equipment found across numerous industries including manufacturing, food processing, pharmaceuticals, and woodworking. They are particularly effective in applications where fine particulate matter needs to be controlled—think grain handling or metalworking operations where airborne dust can pose health risks. By employing a baghouse dust collector, industries can significantly reduce emissions while improving workplace safety.

Comparing Baghouse to Cyclone Dust Collector

Now let’s dive into the age-old debate: which is better—the baghouse or cyclone dust collector? While both systems aim to reduce airborne particulates effectively, they operate based on different principles. A cyclone dust collector uses centrifugal force to separate particles from airflow without filters, making it less effective for very fine particles compared to a baghouse system that excels at capturing small particulates through its fabric filters.

Baghouse Dust Collector Working Principle

Understanding the baghouse dust collector working principle is crucial for optimizing its performance in various industrial applications. Essentially, it involves a sophisticated filtration process that efficiently captures airborne particulate pollutants while maintaining high air quality standards. This section delves into how a baghouse functions, its effectiveness in removing contaminants, and the significance of selecting the right bag material.

Filtration Process Explained

The filtration process of a baghouse dust collector is both simple and ingenious. Air laden with dust and particulates enters the system and is forced through fabric filter bags that trap these unwanted particles while allowing clean air to escape. This method not only enhances air quality but also minimizes environmental impact, making it an essential component in industries where clean air is paramount.

The effectiveness of this filtration process can be attributed to several factors, including the design of the filter bags and their arrangement within the collector. As air passes through these bags, larger particles are captured on the surface while smaller ones penetrate deeper into the fabric material. The result? A highly efficient removal of contaminants that keeps your workspace healthy and compliant with regulations.

How Does Baghouse Remove Particulate Pollutant?

So, how does a baghouse remove particulate pollutants? The answer lies in its multi-step operation that combines mechanical separation and gravity-assisted cleaning mechanisms. Initially, when contaminated air enters the system, it encounters a series of filters that progressively capture larger particles before they can pass through.

Once trapped within the fabric filters, these particulates accumulate over time, necessitating periodic cleaning to maintain optimal airflow efficiency. Most baghouses use an automated pulse-jet cleaning system that blasts compressed air through each filter bag to dislodge accumulated dust back into a collection hopper for disposal or recycling. This continuous cycle ensures that your operations run smoothly without compromising on cleanliness or efficiency.

Importance of Bag Material Selection

When considering what is a baghouse dust collector's most critical components, one cannot overlook the importance of bag material selection. The type of fabric used for filter bags plays a significant role in determining filtration efficiency and durability under various operating conditions. Choosing materials tailored for specific applications can enhance performance by optimizing particle retention while minimizing pressure drop across filters.

Different materials such as polyester, polypropylene, or fiberglass offer unique benefits depending on temperature tolerance and chemical exposure levels prevalent in your industry sector. For example, if you're dealing with high temperatures or corrosive substances, selecting specialized fabrics designed to withstand such conditions will ensure longevity and reliability in your dust collection system.

In summary, understanding how does a baghouse remove particulate pollutant hinges significantly on effective filtration processes paired with appropriate material choices—ensuring you get maximum value from your investment while maintaining compliance with environmental standards.

Advantages of Baghouse Dust Collectors

Baghouse dust collectors are renowned for their effectiveness in creating cleaner air environments across various industries. Their design and functionality provide numerous advantages that contribute to improved air quality, cost savings, and environmental compliance. Understanding these benefits can help businesses make informed decisions about their dust collection systems.

Efficiency in Air Quality Improvement

One of the primary advantages of a baghouse dust collector is its remarkable efficiency in air quality improvement. The baghouse dust collector working principle revolves around capturing fine particulate pollutants from industrial processes, ensuring that harmful substances are filtered out before they can enter the atmosphere. This leads to a significant reduction in airborne contaminants, making it an ideal choice for industries where clean air is paramount.

The filtration process utilized by baghouses is superior to many alternatives, including cyclone dust collectors, as it captures smaller particles that might otherwise escape into the environment. As a result, facilities utilizing baghouse systems can achieve compliance with stringent air quality regulations while safeguarding employee health and safety. By choosing a baghouse dust collector, companies not only enhance their operational efficiency but also contribute positively to public health.

Cost-Effectiveness Over Time

When considering the question Which is better: baghouse or cartridge dust collector?, it's essential to evaluate long-term cost-effectiveness alongside initial investments. While cartridge systems may have lower upfront costs, baghouses typically offer greater durability and require less frequent maintenance or replacement of parts over time. This translates into substantial savings for businesses as they avoid the ongoing expenses associated with more frequent replacements.

Moreover, because of their efficient filtration capabilities, baghouses often lead to reduced energy costs due to lower fan power requirements when compared with other systems like wet scrubbers or cyclone dust collectors. The longevity and efficiency of a baghouse dust collector mean that companies can expect a solid return on investment while improving overall operational productivity. Thus, investing in a quality baghouse system proves beneficial both financially and environmentally over time.

Environmental Compliance Benefits

In today's regulatory landscape, environmental compliance has become increasingly critical for businesses across all sectors. Baghouse dust collectors play an essential role in helping organizations meet these requirements by effectively removing particulate pollutants from exhaust streams before they reach the atmosphere. This capability not only helps prevent fines and penalties associated with non-compliance but also enhances corporate reputation as environmentally responsible entities.

Additionally, as industries strive for sustainability initiatives and reduced carbon footprints, opting for efficient air purification technologies like a baghouse becomes even more relevant. With regulations tightening globally regarding emissions standards, having robust solutions such as a baghouse ensures companies remain ahead of the curve while contributing positively to environmental preservation efforts. Ultimately, investing in effective pollution control technologies like this supports both business objectives and broader ecological goals.

Choosing Between Baghouse and Cartridge Systems

Each system has its unique strengths and weaknesses, making the decision largely dependent on specific operational needs. Understanding these differences can help you determine which is better suited for your application: a baghouse dust collector or a cartridge system.

Which is Better: Baghouse or Cartridge Dust Collector?

To answer the question, Which is better: baghouse or cartridge dust collector?, we first need to consider their fundamental designs and intended uses. A baghouse dust collector typically excels in high-volume applications where large quantities of particulate matter are generated, while cartridge systems are more compact and suitable for lower volume operations. Ultimately, the choice hinges on factors such as space availability, airflow requirements, and specific filtration needs.

Baghouse systems utilize large fabric filters known as bags that capture particulates effectively due to their extensive surface area. On the other hand, cartridge systems feature cylindrical filters that can be more efficient in certain applications but may not handle heavy loads as well as a baghouse would. Therefore, if you're dealing with significant particulate emissions from processes like woodworking or metalworking, understanding what is a baghouse dust collector could lead you to favor this option over cartridges.

Performance Differences and Use Cases

Performance differences between a baghouse dust collector and a cyclone dust collector also play a crucial role in deciding which system best fits your needs. The filtration efficiency of a baghouse is generally superior when it comes to capturing fine particles due to its advanced filtration media design. In contrast, cyclone collectors primarily rely on centrifugal force for particle separation; they are effective for larger particles but may struggle with finer dust.

In terms of use cases, industries such as cement manufacturing or food processing often benefit from the robust capabilities of a baghouse system due to its ability to handle high volumes of particulates without sacrificing air quality. Conversely, if your operation generates lighter or less dense materials—like sawdust—cartridge systems might provide adequate performance while occupying less space. Understanding how does baghouse remove particulate pollutant can also clarify why many industries prefer this method for stringent air quality regulations.

Maintenance Considerations

Maintenance considerations can significantly influence your choice between these two types of dust collectors. Baghouses typically require periodic cleaning cycles where accumulated dust is dislodged from filter bags using either mechanical shaking or reverse airflow techniques; this ensures consistent performance but may demand more time investment compared to simpler cartridge replacements. However, because they handle larger volumes effectively over extended periods without frequent interventions, their overall maintenance costs could be lower in high-load scenarios.

In contrast, cartridge systems tend to be easier to maintain since changing out cartridges requires less effort than cleaning an entire bank of bags in a baghouse system. Yet their shorter lifespan under heavy load conditions might lead you back into maintenance sooner than expected—something worth considering when evaluating total cost ownership over time!

As you weigh your options between these two technologies—baghouses versus cartridges—it’s essential not only to think about immediate needs but also future growth potential within your facility's operations.

Alternatives to Baghouse Systems

Is a Wet Scrubber Better than a Baghouse?

Wet scrubbers are designed to capture particulate pollutants by using liquid, usually water, to wash them out of the air stream. While baghouse dust collectors excel in dry applications and are highly effective at removing particulate matter, wet scrubbers can be better suited for certain industries where moisture is acceptable or beneficial. However, whether a wet scrubber is better than a baghouse depends on factors like the type of pollutants being captured and the desired efficiency in removing those pollutants.

In many cases, a baghouse dust collector may outperform a wet scrubber when it comes to dry particulates due to its filtration capabilities and lower maintenance requirements. The baghouse dust collector working principle revolves around fabric filtration that captures particles effectively without introducing additional moisture into the environment. Ultimately, choosing between these systems requires careful analysis of operational conditions and pollutant types.

Other Dust Collection Technologies

Beyond baghouses and wet scrubbers, several other dust collection technologies exist that cater to various industrial needs. Cyclone dust collectors are another popular option; they leverage centrifugal force to separate larger particles from the air stream effectively before finer filtration occurs in secondary systems like baghouses or cartridge filters. This two-stage approach can enhance overall efficiency while reducing wear on primary filters.

Electrostatic precipitators (ESPs) also serve as viable alternatives by using electrical charges to remove particles from gases without physical filtration media like those found in a baghouse dust collector. These systems work well for fine particulate matter but may not be as effective for larger particles or sticky substances that could clog traditional filters. Each technology presents unique advantages depending on specific industrial applications and goals regarding air quality improvement.

Industry Trends in Air Purification

The landscape of air purification is constantly evolving with advancements in technology and increasing regulatory pressures for cleaner air standards across industries. One significant trend is the growing integration of smart technology into traditional systems like baghouses—allowing real-time monitoring of performance metrics such as airflow rates and filter conditions. This shift not only enhances efficiency but also minimizes downtime through predictive maintenance strategies.

Moreover, there’s an increasing focus on sustainability within industries leading to innovations aimed at reducing energy consumption associated with dust collection processes—making both baghouses and alternative systems more eco-friendly over time. As companies strive for environmental compliance benefits while maintaining productivity levels, understanding options beyond just What is a baghouse? becomes crucial for informed decision-making regarding air quality solutions.

Conclusion

In the quest for cleaner air, understanding the role of a baghouse dust collector becomes increasingly vital. The health implications of poor air quality are profound, affecting everything from respiratory issues to overall well-being. By investing in effective dust collection systems, industries can significantly contribute to a healthier environment for their workers and communities.

The Impact of Clean Air on Health

Clean air is not just a luxury; it's a necessity for maintaining good health. Poor air quality can lead to serious health problems, including asthma, lung disease, and cardiovascular issues. Implementing systems like the baghouse dust collector can dramatically reduce airborne pollutants, thus improving the overall air quality and safeguarding public health.

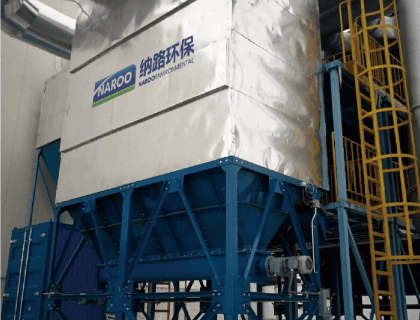

NAROO's Role in Air Quality Solutions

NAROO has positioned itself as a leader in providing innovative air quality solutions that include advanced baghouse dust collectors. By focusing on high-efficiency filtration technologies, NAROO helps industries meet stringent environmental regulations while enhancing workplace safety. Their commitment to sustainability and clean air solutions ensures that businesses can thrive without compromising on health.

Future of Baghouse Dust Collectors in Industry

The future looks bright for baghouse dust collectors as industries continue to prioritize environmental compliance and worker safety. With advancements in filtration technology and materials, these systems are becoming more efficient at removing particulate pollutants than ever before—answering questions like How does a baghouse remove particulate pollutant? effectively. As alternative technologies emerge, such as wet scrubbers or cyclone dust collectors, the ongoing debate about Which is better: baghouse or cartridge dust collector? will shape innovations that enhance performance across various applications.